Borophosphate fluorescent powder capable of emitting green fluorescence as well as preparation method and application of borophosphate fluorescent powder

A borophosphate and green fluorescence technology, applied in the field of borophosphate phosphor and its preparation, can solve the problem of high price, and achieve the effects of easy mass production, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of above-mentioned borophosphate fluorescent powder, it comprises the following steps:

[0026] NH first 4 h 2 PO 4 、H 3 BO 3 , Ln 2 o 3 (Ln is one or a combination of La, Gd, Yb and Lu) and Tb 4 o 7 as raw material, press (Ln 1-x Tb x ) 7 o 6 (BO 3 )(PO 4 ) 2 (0.01≤x≤0.1) The stoichiometric ratio is used for batching, after grinding, it is placed in a covered alumina crucible and heated at 300-500°C for 6-12 hours to obtain the initial product; NH 4 h 2 PO 4 、H 3 BO 3 , Ln 2 o 3 and Tb 4 o 7 These raw materials are low in cost and easy to obtain, and the reaction conditions of this step are easy to control.

[0027] Then the initial product obtained in the first step is ground and pressed into a disc with a diameter of 1 to 5 cm (the pressure of the initial product pressed into a disc is preferably 150 to 200Mpa), and placed in a covered platinum crucible; The product is ground and pressed into a disc, which can reduce the...

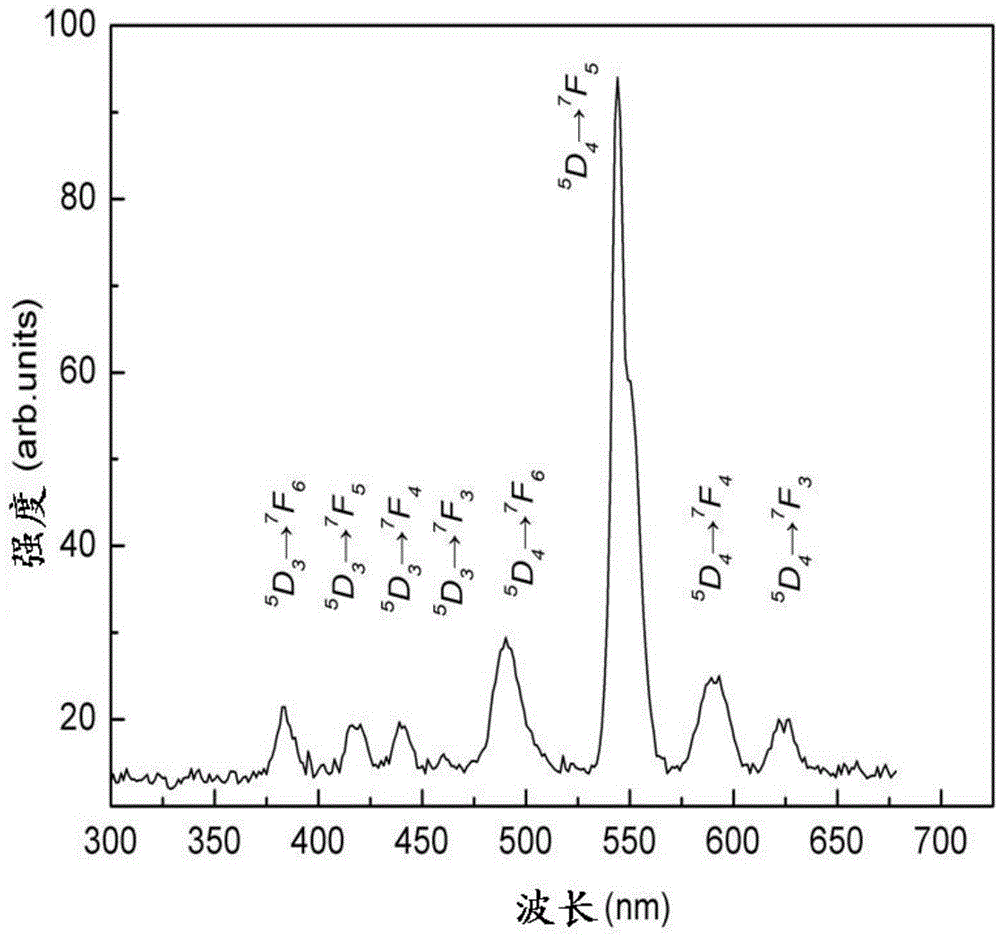

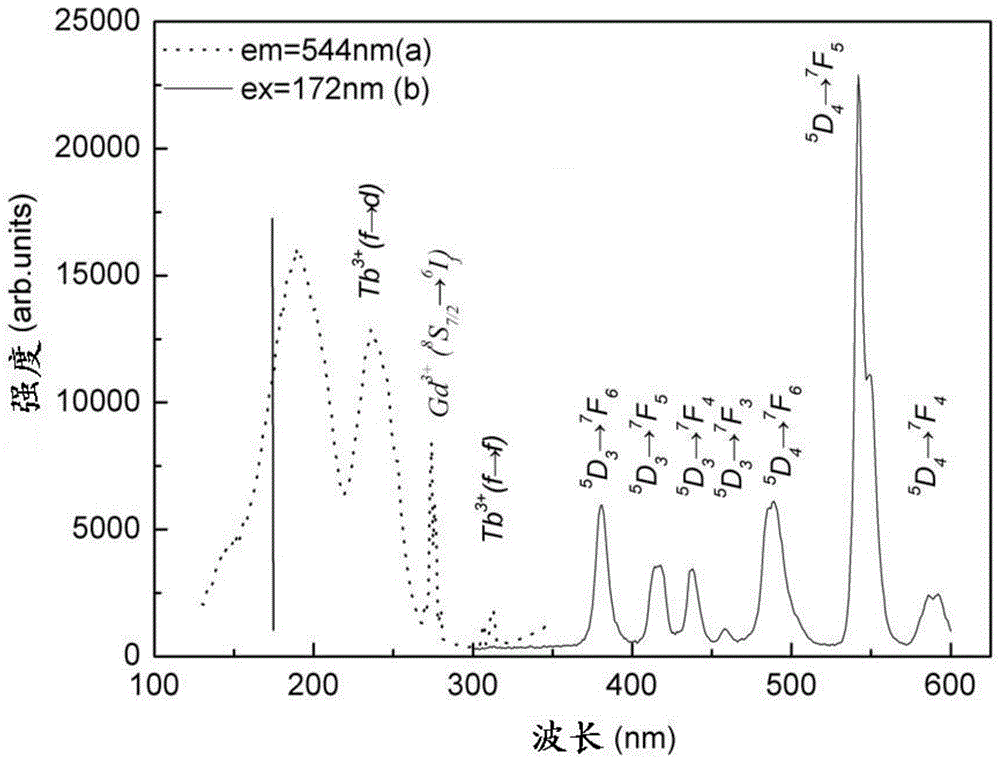

Embodiment 1

[0032] This embodiment provides a kind of borophosphate fluorescent powder, and its chemical formula is: Gd 6.3 Tb 0.7 o 6 (BO 3 )(PO 4 ) 2 , in order to prepare the phosphor, the specific operation is: weigh NH 4 h 2 PO 4 (Analytical pure) 1.38g, H 3 BO 3 (Analytical pure) 0.37g, Gd 2 o 3 (99.99%) 6.85g and Tb 4 o 7 (99.99%) 0.785g, fully ground and mixed in an agate mortar, then placed in an alumina crucible and closed the lid, placed in a muffle furnace and heated at 500°C for 6 hours; then the primary product after heating and reaction Put it in an agate mortar and grind it thoroughly, then pour it into a tablet press and press it into a disc with a diameter of 5 cm under 150 MPa, put the disc in a covered platinum crucible, and then place the platinum crucible in a place containing a large amount of carbon In the muffle furnace of the powder, the temperature is raised to 1000°C at a rate of 5°C per minute, and it is calcined for 30 hours and then naturally co...

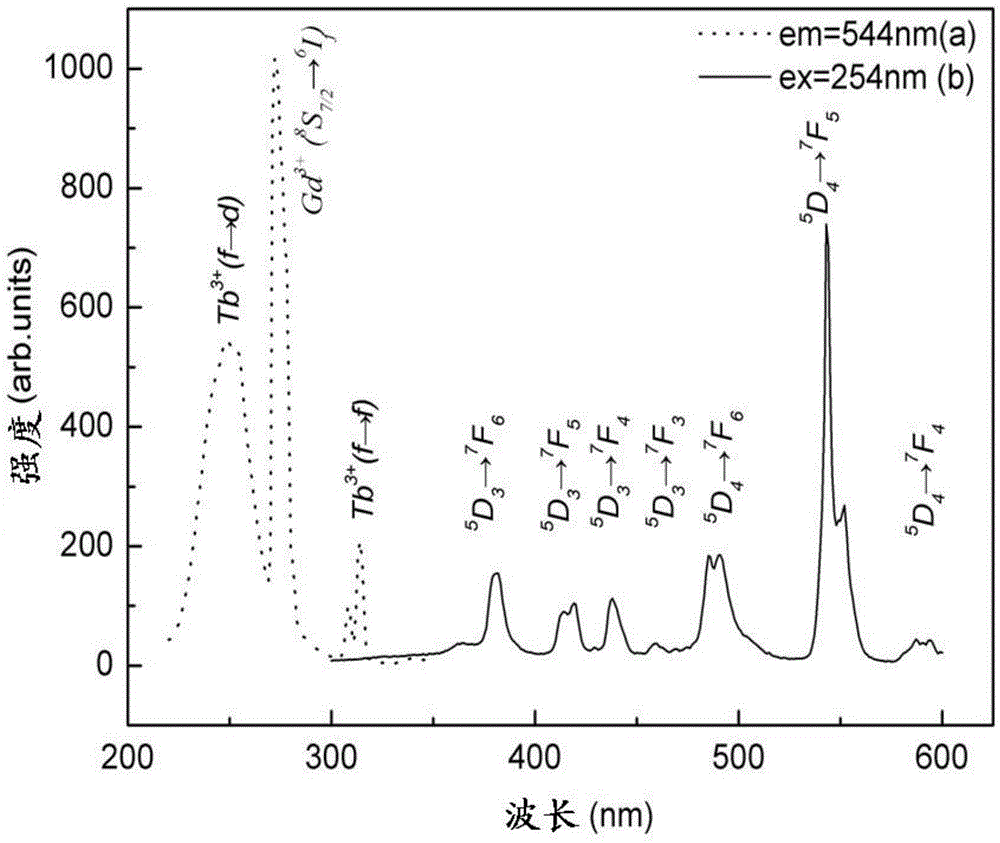

Embodiment 2

[0034] This embodiment provides a kind of borophosphate fluorescent powder, and its chemical formula is: Gd 6.93 Tb 0.07 o 6 (BO 3 )(PO 4 ) 2 , in order to prepare the phosphor, the specific operation is: weigh NH 4 h 2 PO 4 (analytical pure) 1.38 g, H 3 BO 3 (Analytically pure) 0.37 g, Gd 2 o 3 (99.99%) 7.53 g and Tb 4 o 7 (99.99%) 0.079 g, thoroughly ground and mixed in an agate mortar, then placed in an alumina crucible with the lid closed and heated in a muffle furnace at 300°C for 12 hours; then the primary product after heating reaction Put it in an agate mortar and grind it thoroughly, then pour it into a tablet press and press it into a disc with a diameter of 1 cm under 200 MPa, put the disc in a covered platinum crucible, and then place the platinum crucible in a place containing a large amount of carbon In the muffle furnace of the powder, the temperature is raised to 1500°C at a rate of 10°C per minute, calcined for 12 hours, and then naturally cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com