Novel transformer anti-aging mixed insulating oil and preparation method thereof

A technology for insulating oil and transformers, which is applied in the field of new transformer anti-aging mixed insulating oil and its preparation, which can solve the problems of increasing the production cost of insulating oil, poor biodegradability, and low water saturation of mineral insulating oil, so as to improve safety and reliability, Good heat dissipation performance and the effect of inhibiting insulation aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention are described in detail below.

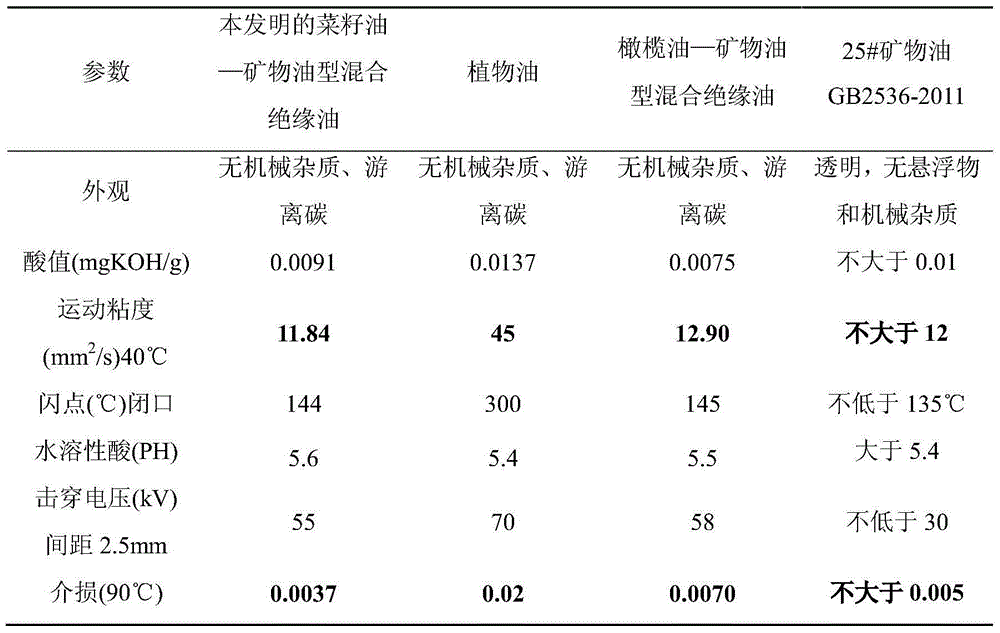

[0028] The invention provides a novel anti-aging mixed insulating oil for transformers. The mixed insulating oil includes the following raw materials in weight percentage: refined rapeseed oil, 15%; mineral insulating oil, 85%.

[0029] Among them, rapeseed oil is obtained by refining rapeseed crude oil, and mineral insulating oil is 25# transformer insulating oil. The novel transformer anti-aging mixed insulating oil also includes an antioxidant, the antioxidant is 2,6-di-tert-butyl-p-cresol, and the weight percentage of the 2,6-di-tert-butyl-p-cresol is 0.3%.

[0030] A preparation method of a novel transformer anti-aging mixed insulating oil is as follows:

[0031] (1) Refining of Rapeseed Crude Oil

[0032] ① Alkali refining and deacidification: add 2% NaOH solution to the crude vegetable oil at 75°C and normal pressure to carry out alkali neutralization reaction to remove acid impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com