Pore-forming construction method by mixing high pressure water with air in long screw pile in high clay layer

A construction method and long spiral technology, which is applied in earthwork drilling, sheet pile walls, foundation structure engineering, etc., can solve problems such as inability to drill, long spiral drilling cannot be applied, etc., achieves fast pile formation and improves construction efficiency , the effect of reducing side resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

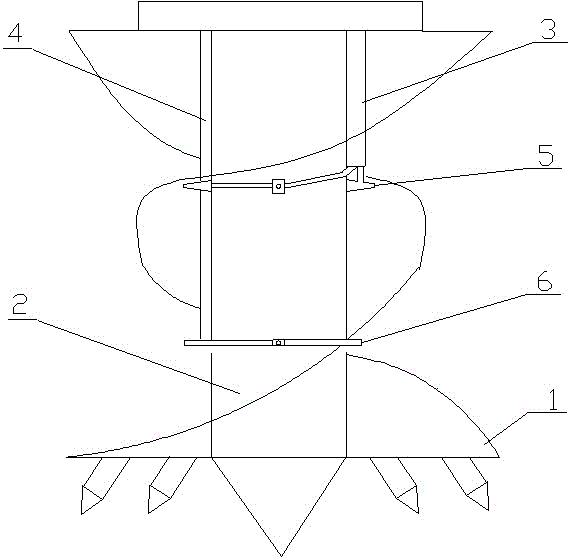

[0015] A construction method for forming holes by mixing high-pressure water and air with long screw piles in high-cohesive soil layers, comprising the following steps:

[0016] Step 1: install a multi-channel central flow divider under the power head of the long screw pile driver, and install high-pressure water pipes and gas pipes with spray heads on the outside of the long auger drill pipe;

[0017] Step 2: when the drill bit 1 drills to the cohesive soil layer, use the high-pressure water injection pump to inject high-pressure water into the high-pressure water delivery pipe 3, and the high-pressure sprayed water flow cuts the cohesive soil between the spiral blades, so that the cohesive soil forms pieces;

[0018] The third step: use the air compressor to press air into the air pipe 4;

[0019] Step 4: A mixture of water, air and soil is formed at the bottom of the pile, and under the action of the rotary thrust of the drill pipe, it goes up to the pile hole along the hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com