Multifunctional composite pipe silencer

A composite and muffler technology, which is applied in the direction of pipe components, non-variable pumps, machines/engines, etc., can solve the problems of loss, noise pollution, noise enhancement, etc., and achieve the effect of improving service life and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

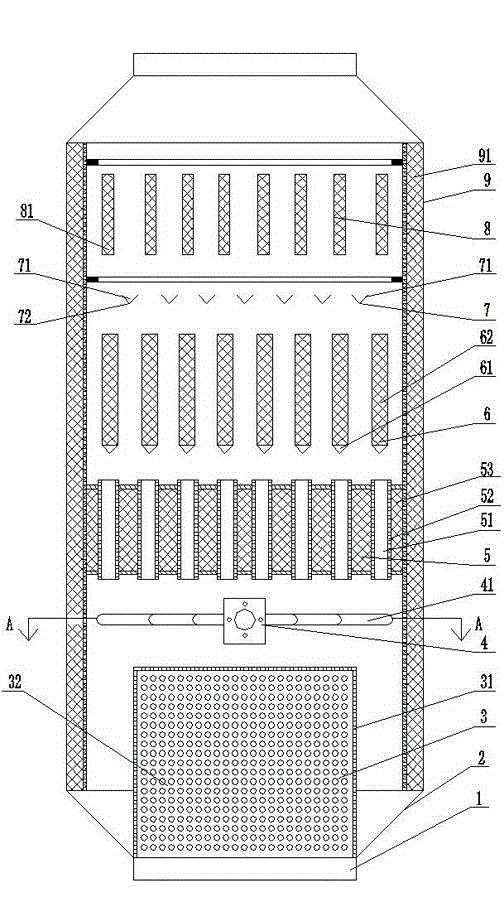

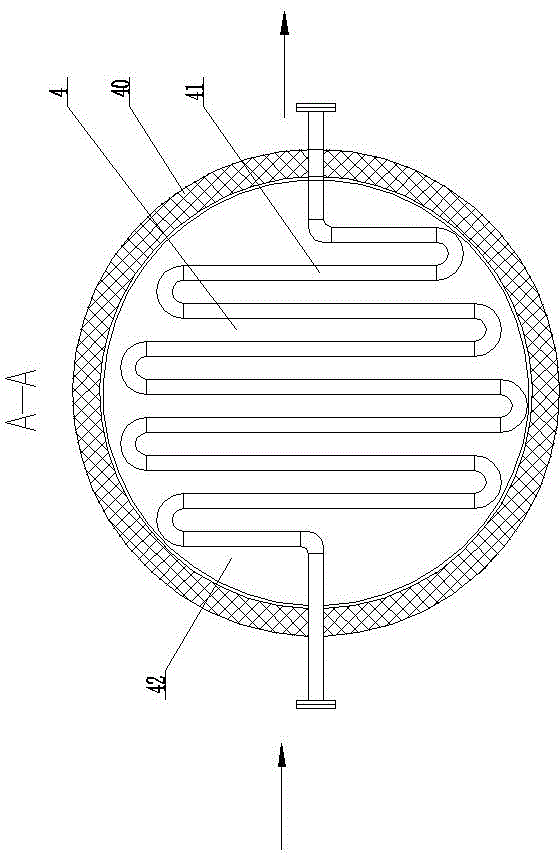

[0022] Embodiment 1, with reference to figure 1 and figure 2 , a multifunctional composite pipe muffler, including an exhaust cylinder 9 with an air inlet and an air outlet, and a capacity expansion and pressure reduction device 3 and a cooling and energy storage device 4 arranged in sequence in the chamber of the exhaust cylinder , FM sound-absorbing device 5, low-frequency noise reduction device 6, high-frequency noise reduction device 7 and sound resistance device 8; the air inlet of the exhaust cylinder 9 is connected with the exhaust pipe 1 through a short connection 2; the expansion and pressure reduction The device 3 has an air inlet passage 32 connected to the air inlet, and a plurality of air holes 31 for connecting the air inlet passage 32 and the exhaust cylinder chamber are provided on the peripheral surface of the expansion and pressure reduction device; The device 4 includes a cooling liquid circulation chamber 40 with a ventilation cavity 42 and a cooling liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com