Maintenance-free vacuum heat-insulation fluid heat energy delivery pipe

A technology for vacuum insulation and conveying pipelines, applied in the direction of thermal insulation protection of pipelines, pipeline protection, pipes, etc., can solve the problems of large heat loss, low energy density of new energy, low temperature, etc., so as to reduce the heat loss rate and operating cost. , The effect of saving primary energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

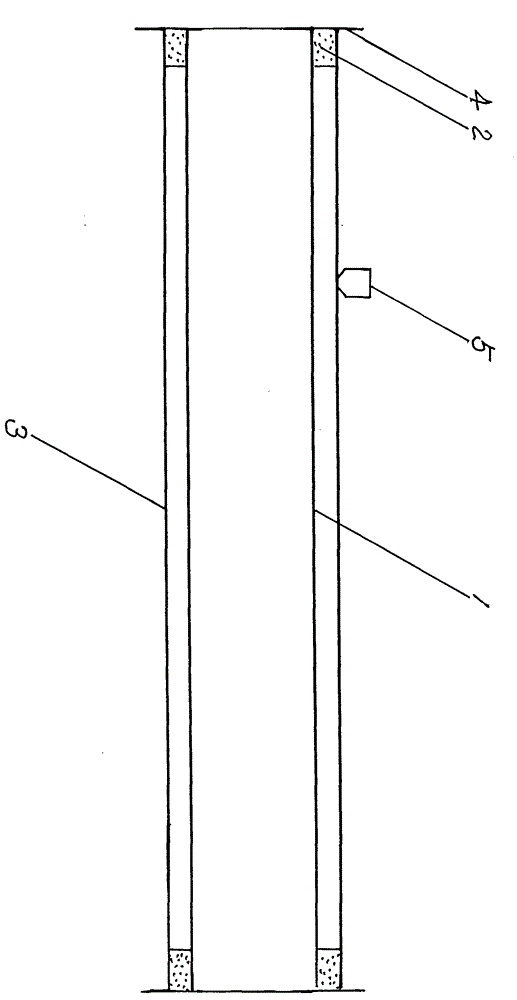

[0034] Example 1 The diameter of the inner tube is φ300mm and the length is 10M. The base material of the inner tube is stainless steel or low-alloy steel, and the base material of the outer tube is carbon steel.

[0035] Embodiment 1 is applied to seawater, river water, sewage, and geothermal water in urban power generation, heating, and heating projects, or in traditional coal, oil, and natural gas thermal power generation, heating, and heating projects.

[0036] The maximum working temperature is 650°C, and it can be used in the delivery system of high-temperature and high-pressure steam for turbogenerators. Its heat loss is reduced from 10-30% of equivalent traditional insulated pipes to 1%.

Embodiment 2

[0037] Example 2 The diameter of the inner tube is φ1200mm and the length is 10M. The base material of the inner tube is carbon steel, and the inner surface is heat-treated. The base material of the outer tube is carbon steel, and the outer surface is treated with anticorrosion. Embodiment 2 is applied to the central heating project for power generation and central heating of biomass renewable energy, environment-friendly and low-carbon cities. It is suitable for domestic sewage in urban pipelines, geothermal water or technical transformation projects in existing urban central heating pipelines. Its heat loss rate is reduced from 10-30% to 1% per 10 kilometers (Km) of the same insulation pipeline, and correspondingly saves 90% of primary energy coal, oil, and natural gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com