An anti-slagging gas turbine combustor using biomass fuel

A biomass fuel and gas turbine technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problem of serious slagging of biomass fuel, reduce the probability of slagging, reduce the problem of air pollution, and reduce the burning time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

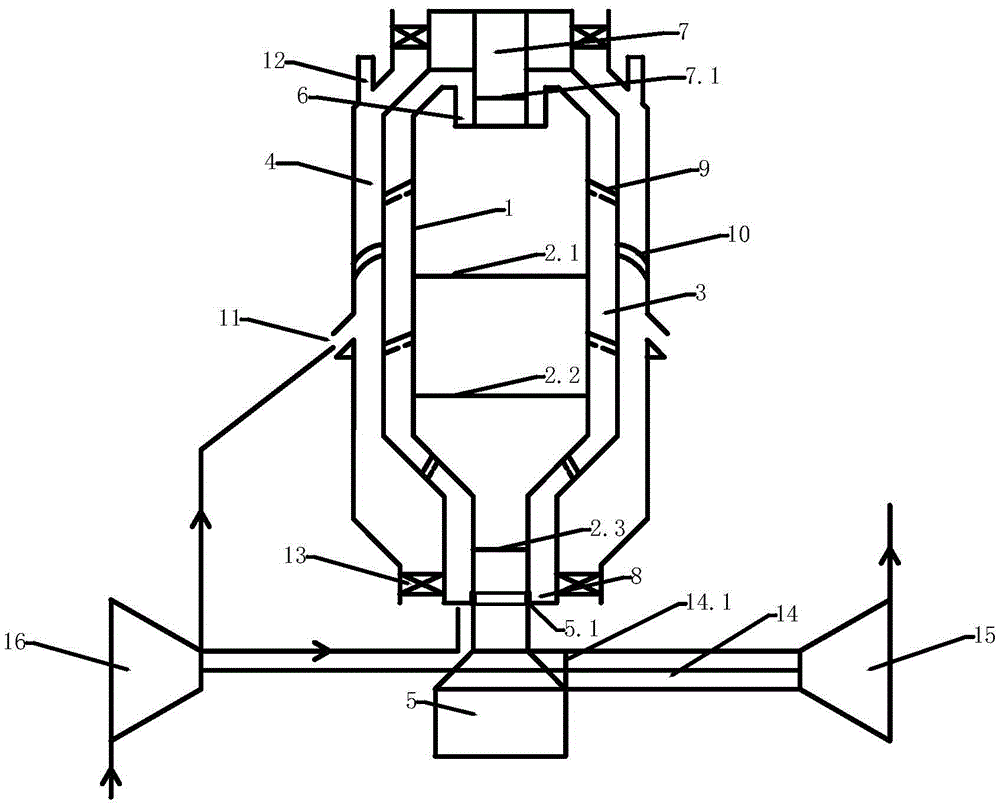

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

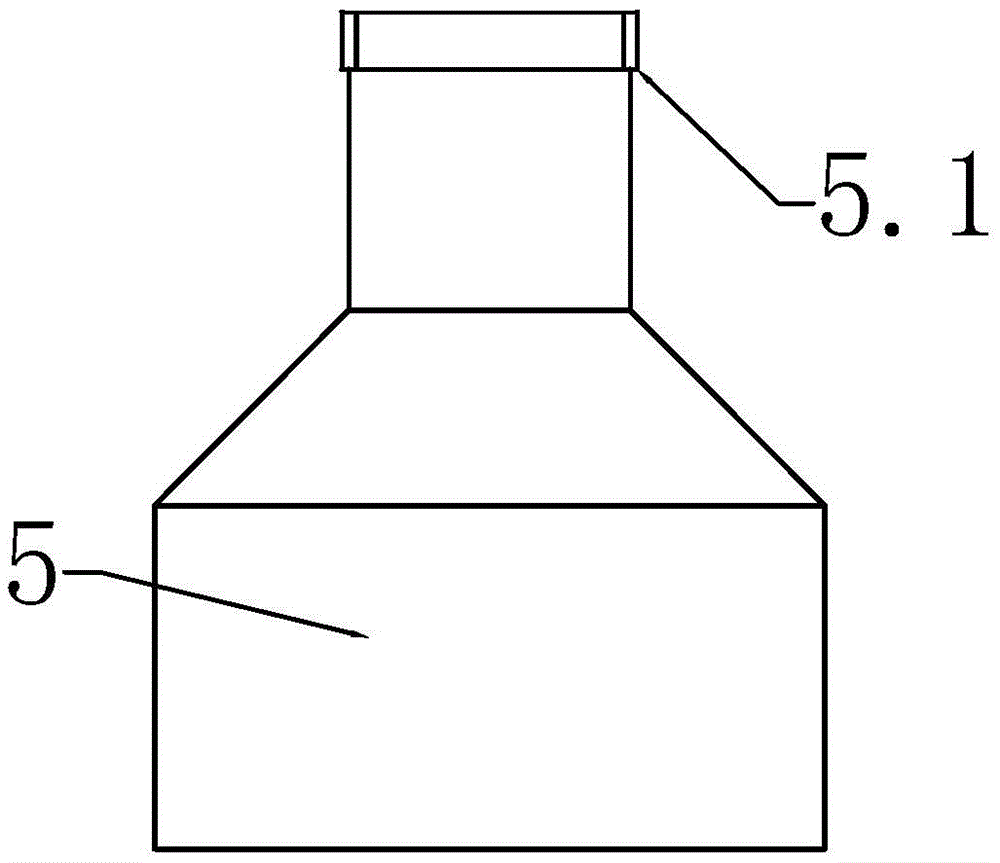

[0027] Such as figure 1 As shown, a kind of anti-slagging gas turbine combustor chamber utilizing biomass fuel in the present invention comprises a combustor 1, an air layer 3 and a cylinder liner layer 4 arranged sequentially from the inside to the outside; wherein, the bottom end of the combustor 1 is arranged In the annular clamping groove 5.1 at the top of the ash collector 5, and the bottom end of the combustion chamber 1 can rotate freely in the annular clamping groove 5.1, and the top of the combustion chamber 1 is provided with a combustion chamber air inlet 6 and a fuel inlet in sequence from bottom to top Channel 7, the fuel inlet channel 7 is provided with a rotary valve 7.1, and the combustion chamber 1 is provided with several layers of perforated fire grates.

[0028] The air layer 3 and the combustion chamber 1 are rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com