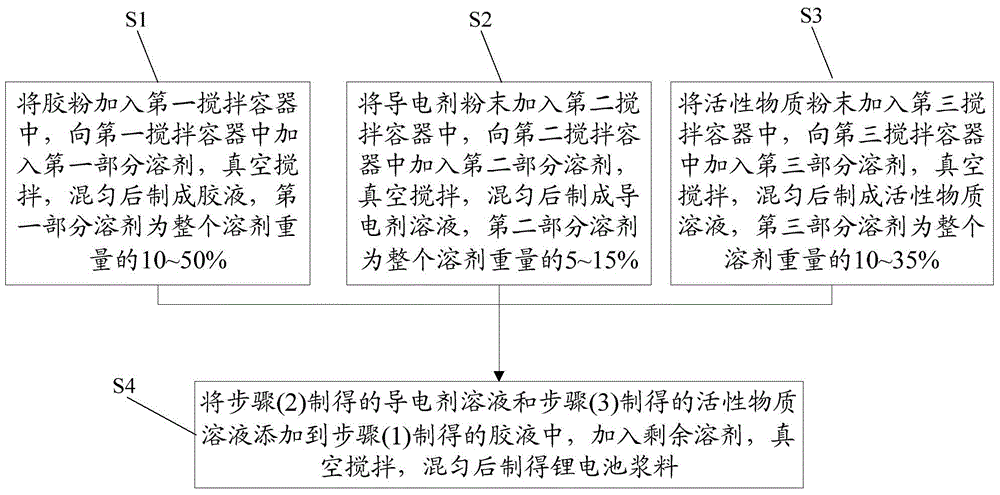

Preparation process of lithium battery slurry

A preparation process, lithium battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor stability, long process time, poor quality, etc., and achieve the effect of short process time and uniform slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the positive electrode active material is lithium nickel cobalt manganese oxide, the rubber powder is PVDF (polyvinylidene fluoride), the solvent is NMP (N-methylpyrrolidone), and the conductive agent is carbon black.

[0035] Clean the mixing tank of the double planetary power mixer, add all the rubber powder and solvent accounting for 10% of the total solvent weight, turn on the revolution and stir at a low speed, control the stirring speed at 10RPM, and vacuum, the vacuum degree is -0.085MPa~-0.095MPa. When finally forming a transparent gel-like liquid, it is made into a glue solution.

[0036] At the same time, pre-mix the conductive agent with a solvent accounting for 15% of the total solvent weight, turn on the revolution and stir at a low speed, control the stirring speed at 8RPM, vacuumize, the vacuum degree is -0.085MPa~-0.095MPa, and mix well to make a conductive agent solution Pre-mix the active substance with a solvent accounting for 35% ...

Embodiment 2

[0039] In this embodiment, the positive electrode active material is lithium nickel cobalt manganese oxide, the rubber powder is PVDF (polyvinylidene fluoride), the solvent is NMP (N-methylpyrrolidone), and the conductive agent is carbon black.

[0040] Clean the mixing tank of the double planetary power mixer, add all the rubber powder and the solvent accounting for 10% of the total solvent weight, turn on the revolution and stir at a low speed, the stirring speed is controlled at 10RPM, when the rubber powder is completely soaked and appears viscous, further Add solvent accounting for 40% of the total solvent weight, revolution and stir, the stirring speed is controlled at 10RPM, vacuumize, the vacuum degree is -0.085MPa~-0.095MPa. When finally forming a transparent gel-like liquid, it is made into a glue solution.

[0041] At the same time, pre-mix the conductive agent with a solvent accounting for 15% of the total solvent weight, turn on the revolution and stir at a low sp...

Embodiment 3

[0044] In this embodiment, the negative electrode active material is lithium titanate, the rubber powder is PVDF, the solvent is NMP, and the conductive agent is carbon black.

[0045] Clean the mixing tank of the double planetary power mixer, add all the rubber powder and the solvent accounting for 15% of the total solvent weight, turn on the revolution and stir at a low speed, the stirring speed is controlled at 8RPM, when the rubber powder is completely soaked and viscous, further Add solvent accounting for 35% of the total solvent weight, revolution and stir, the stirring speed is controlled at 10RPM, and vacuumize, the vacuum degree is -0.085MPa~-0.095MPa. When finally forming a transparent gel-like liquid, it is made into a glue solution.

[0046] At the same time, pre-mix the conductive agent with a solvent accounting for 10% of the total solvent weight, turn on the revolution and stir at a low speed, control the stirring speed at 8RPM, vacuumize, the vacuum degree is -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com