Formaldehyde scavenging agent for glue artificial board as well as preparation method thereof

A formaldehyde scavenger, wood-based panel technology, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of low quality of wood-based panel products, poor timeliness, low free formaldehyde removal rate, etc., to improve the removal rate and timeliness, The effect of suppressing overflow and improving the elimination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

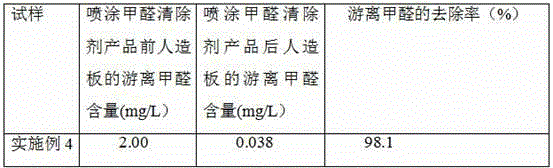

Examples

Embodiment 1

[0032] The invention proposes a formaldehyde scavenger for wood-based panels and a preparation method thereof. The formaldehyde scavenger is a film-forming material that covers the surface of wood-based panels by brushing, spraying or rolling, and can not only form a protective film on the surface of wood-based panels. membrane to prevent the overflow of free formaldehyde, and its active ingredient ethylene urea can also enter the interior of the wood-based panel under the action of the penetrating agent, react with the free formaldehyde in it, and achieve the purpose of eliminating free formaldehyde in the wood-based panel, of course, for To better realize the present invention, in the actual use process, an accelerator is also added in the formaldehyde scavenger, and its purpose is to: play a catalytic role when ethylene urea and free formaldehyde react, and can effectively improve the concentration of free formaldehyde. Elimination rate, proved by practice, its use effect is...

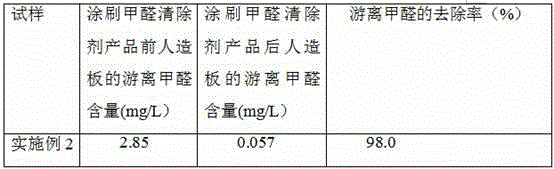

Embodiment 2

[0051] By weight percentage, the formaldehyde scavenger involved in the present embodiment comprises the following components:

[0052] Ethylene urea: 40%;

[0053] Film-forming agent: 30%, polyvinyl alcohol film-forming agent can be used;

[0054] Penetrant: 0.1%, JFC-1 penetrant can be used;

[0055] Accelerator: 10%, a mixture of calcium sulfate and magnesium chloride can be used, the mass ratio of calcium sulfate: magnesium chloride is 1:1;

[0056] Solvent water: 19.9%.

[0057] The preparation process of above-mentioned formaldehyde scavenger is as follows:

[0058] (1) First, prepare ethylene urea with appropriate proportions of ethylenediamine, urea, and water:

[0059] Add ethylenediamine, urea, and water with a molar ratio of 1.5:1:0.5 into the reactor respectively, heat and stir at 240°C, and control the reaction time to 4h. After obtaining ethylene urea paste, continue Heat and stir, after the ethylene urea paste dissolves, cool down to 180°C, then add water t...

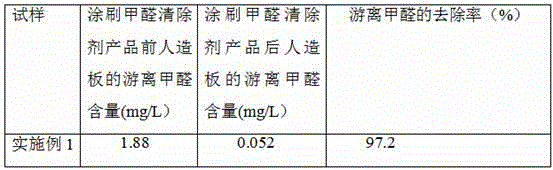

Embodiment 3

[0069] By weight percentage, the formaldehyde scavenger involved in the present embodiment comprises the following components:

[0070] Ethylene urea: 30%;

[0071] Film-forming agent: 25%, sodium alginate film-forming agent can be used;

[0072] Penetrant: 5%, JFC-E penetrant can be used;

[0073] Accelerator: 5%, a mixture of magnesium sulfate, calcium sulfate and calcium chloride can be used, wherein the mass ratio of magnesium sulfate: calcium sulfate: calcium chloride is 1:1:0.5;

[0074] Solvent water: 35%.

[0075] The preparation process of above-mentioned formaldehyde scavenger is as follows:

[0076] (1) First, prepare ethylene urea with appropriate proportions of ethylenediamine, urea, and water:

[0077] Add ethylenediamine, urea, and water with a molar ratio of 1.5:1:0.5 into the reactor respectively, heat and stir at 180°C, and control the reaction time to 3.5h. After obtaining the ethylene urea paste, Continue heating and stirring. After the ethylene urea p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com