Preparation method of reverse osmosis membrane

A technology of reverse osmosis membrane and ultrafiltration membrane, applied in the field of preparation of reverse osmosis membrane, can solve the problems of interfacial polymerization membrane performance difference, high recovery cost, environmental pollution, etc., and achieve the effect of ensuring stability and reducing recovery cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further detail below in conjunction with the embodiments. The present invention will be more fully and better understood when considered in conjunction with the examples. The embodiments described here are used to provide a further understanding of the present invention, and do not constitute an improper limitation of the present invention.

[0019] A kind of preparation method of reverse osmosis membrane, take the aqueous solution of 2.5wt% m-phenylenediamine as the water phase solution, the Isopar G solution of 0.1wt% trimesoyl chloride as the oil phase solution as an example, the film coating parameters of the film coating equipment are : Coating speed 3.5m / s, booster pump flow rate 20m 3 / h, coating distance 300m

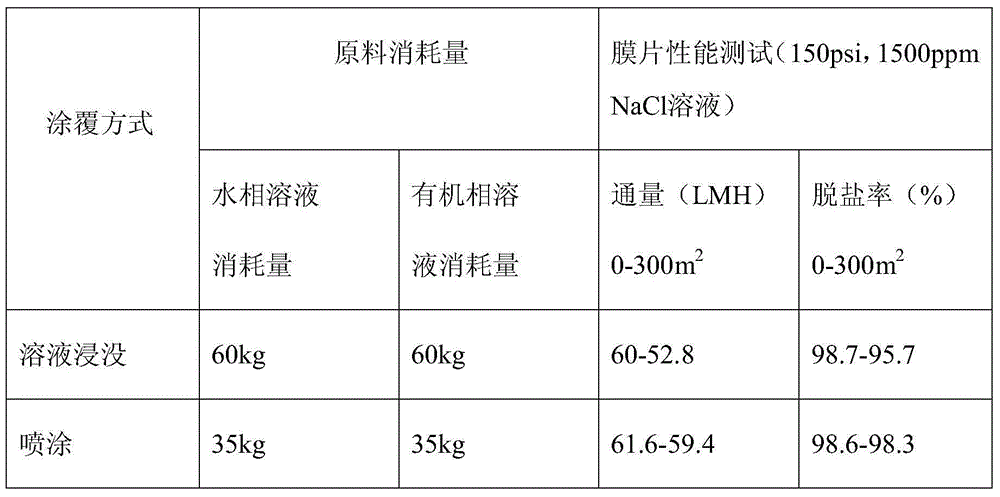

[0020] Production 300m 2 During diaphragm, original dip coating and spraying method of the present invention consume material and film performance contrast as shown in table 1:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com