Method for preparing heavy metal adsorbent

An adsorbent and heavy metal technology, which is applied in the field of heavy metal adsorbent preparation, can solve the problems of difficulty in increasing the grafting rate of cellulose molecules and low accessibility of cellulose, so as to increase economic added value, increase reaction grafting rate, The effect of enhancing chemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

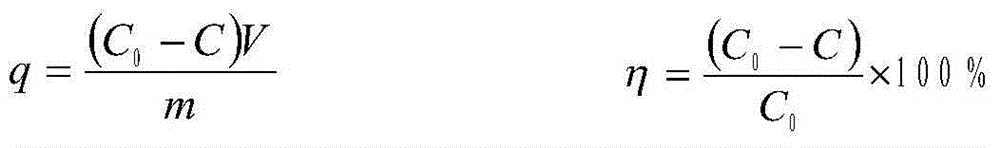

Method used

Image

Examples

Embodiment 1

[0019] A kind of preparation method of heavy metal adsorbent, carries out according to the following steps:

[0020] 1. Preparation of bagasse cellulose:

[0021] After crushing the bagasse, sieve it with a 100-mesh sieve to keep the small parts, add 80ml of 15% NaOH to the bagasse, treat at 120°C for 0.5h, wash with distilled water until neutral, and dry to obtain bagasse cellulose.

[0022] 2. Activation of bagasse cellulose:

[0023] Take 1.0 g of the absolute-dried bagasse cellulose obtained in step 1 and place it in a three-necked flask, add 15 ml of distilled water, and react for 30 minutes under ultrasonic conditions with a power of 150 W to obtain an activated cellulose suspension.

[0024] 3. Graft copolymerization of bagasse cellulose and acrylic acid:

[0025] Take the bagasse cellulose suspension obtained in step 2, add neutralized acrylic acid (sodium hydroxide:acrylic acid mass ratio is 2:3); add initiator ammonium persulfate and N,N'-methylenebisacrylamide in ...

Embodiment 2

[0029] A kind of preparation method of heavy metal adsorbent, carries out according to the following steps:

[0030] 1. Preparation of bagasse cellulose:

[0031] After crushing the bagasse, sieve it with a 100-mesh sieve to keep the fine parts, add 100ml of 20% NaOH to the bagasse, treat at 120°C for 1.0h, wash with distilled water until neutral, and dry to obtain bagasse cellulose.

[0032] 2. Activation of bagasse cellulose:

[0033] Take 1.0 g of the absolute-dried bagasse cellulose obtained in step 1 and place it in a three-necked flask, add 18 ml of distilled water, and react for 30 minutes under ultrasonic conditions with a power of 300 W to obtain an activated cellulose suspension.

[0034] 3. Graft copolymerization of bagasse cellulose and acrylic acid:

[0035] Take the bagasse cellulose suspension obtained in step 2, add neutralized acrylic acid (sodium hydroxide:acrylic acid mass ratio is 2:5); add initiator potassium persulfate and N,N'-methylenebisacrylamide in...

Embodiment 3

[0039] A kind of preparation method of heavy metal adsorbent, carries out according to the following steps:

[0040] 1. Preparation of bagasse cellulose:

[0041] After crushing the bagasse, sieve it with a 100-mesh sieve to keep the fine parts, add 120ml of 20% NaOH to the bagasse, treat at 120°C for 1.0h, wash with distilled water until neutral, and dry to obtain bagasse cellulose.

[0042] 2. Activation of bagasse cellulose:

[0043] Take 1.0 g of the absolute-dried bagasse cellulose obtained in step 1 and place it in a three-necked flask, add 18 ml of distilled water, and react for 30 minutes under ultrasonic conditions with a power of 400 W to obtain an activated cellulose suspension.

[0044] 3. Graft copolymerization of bagasse cellulose and acrylic acid:

[0045] Take the bagasse cellulose suspension obtained in step 2, add neutralized acrylic acid (sodium hydroxide: acrylic acid mass ratio is 2:7); add initiator ammonium persulfate and N,N'-methylenebisacrylamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com