Argon-arc welding fixture for T-shaped components

A technology of argon arc welding and parts, applied in the field of argon arc welding fixtures of T-shaped parts, can solve the problems of high cost, affecting material performance, high hardness, etc., achieve the effect of protecting material performance and overcoming the increase in hardness and strength of weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

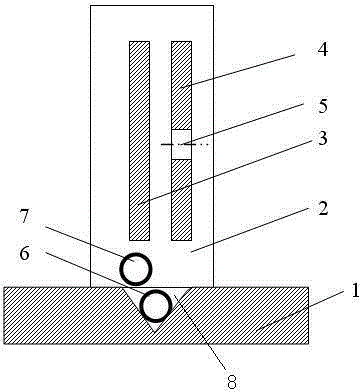

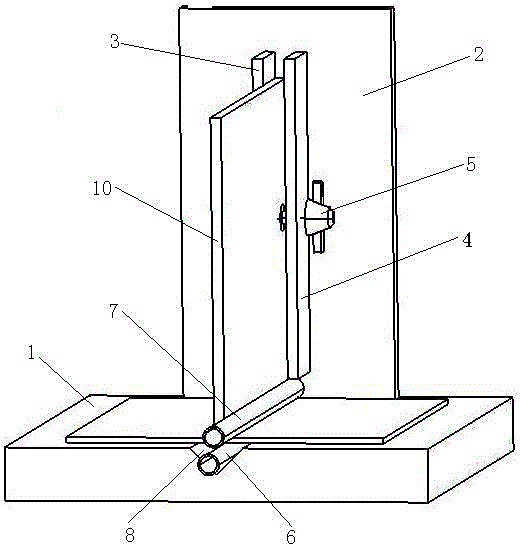

[0014] Example: see figure 1 , figure 2 , image 3 .

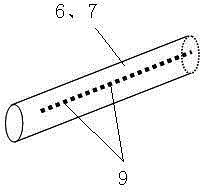

[0015] A T-shaped part argon arc welding fixture, including a column plate 2, a base plate 1, two positioning baffles 3, 4, divided into two left and right pieces, two air guide pipes 6, 7, the column plate 2 is perpendicular to the base plate 1, the left and right positioning blocks 3 and 4 are installed vertically on the column plate 2 to fix the T-shaped part 10, the two air guide pipes 6 and 7 are perpendicular to the column plate 2, and the first air guide pipe 6 is arranged At the lower part of the T-shaped part 10 , the second air guide pipe 7 is arranged at the vertical angle position of the T-shaped part 10 .

[0016] Grooves 8 are formed on the bottom plate 1 at positions corresponding to the two positioning baffles 6 and 7 , and the first air guide pipe 6 is arranged in the grooves 8 .

[0017] Right locating baffle 4 is fixed on the left locating baffle 3 by T-shaped part 10 by jacking bolt 5 that is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com