A beam-splitting laser multi-station time-sharing cutting machine and processing method

A multi-station, cutting machine technology, applied in laser welding equipment, glass cutting equipment, metal processing equipment, etc., can solve the problems of difficulty in adapting to mechanical processing, low efficiency of small arcs, glass surface damage, etc., to improve the cutting effect , fast cutting speed and low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

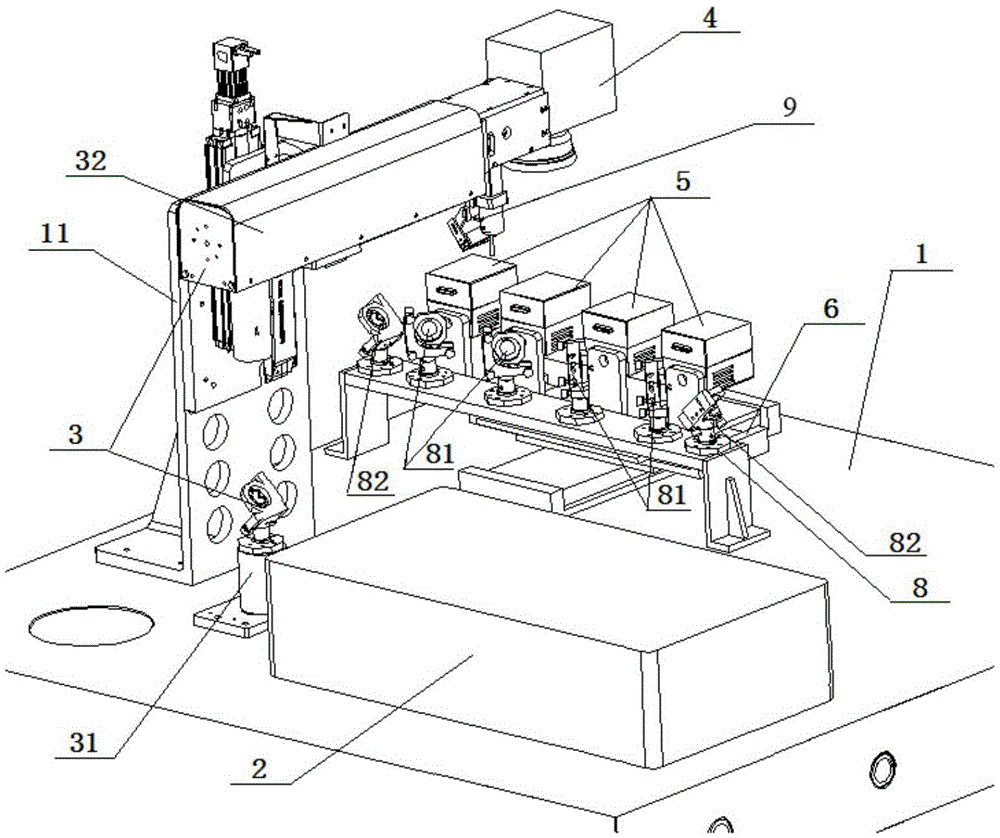

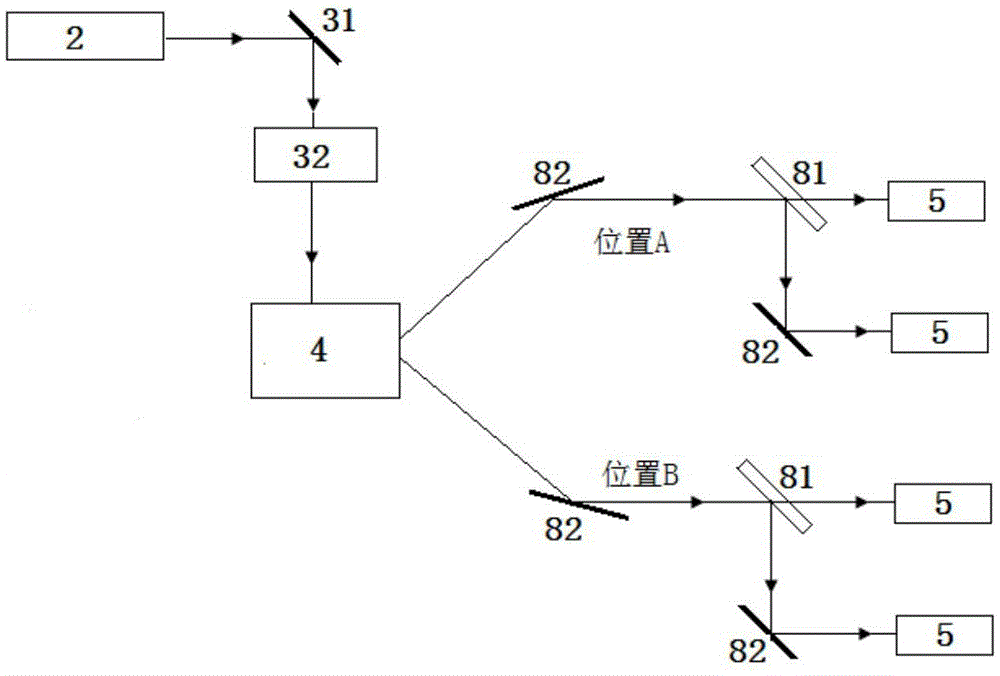

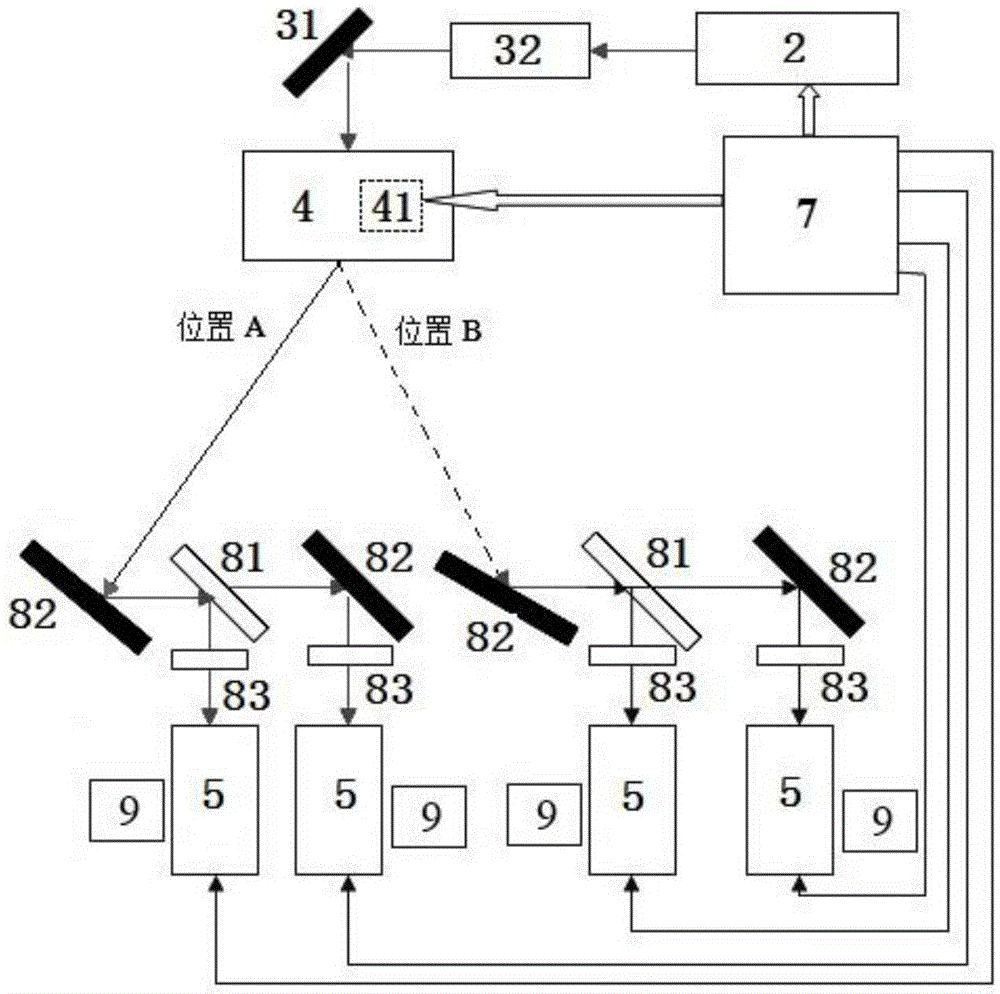

[0034] like figure 1 As shown, the present invention provides a beam-splitting laser multi-station time-sharing cutting machine, including a platform 1, a laser light source 2, an incident mechanism 3, a laser vibrating mirror 4, a processing head 5, a cross moving platform 6, and a beam-splitting mechanism 8 , beam splitter 81, beam splitting mirror 82 and CCD camera 9. The laser light source 2, the incident mechanism 3, and the cross moving platform 6 are installed on the platform 1, the CCD camera 9 is installed under the laser vibrating mirror 4 by bolts, and the beam splitter 81 and the beam splitting mirror 82 are installed on the cross moving platform 6 . The cross moving platform 6 can move in the X and Y directions under the control of the linear motor, and the control accuracy is 10 μm.

[0035] like image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com