Preparation method of graphene film

A technology of graphene film and carbon source, which is applied in the field of integrated circuits, can solve the problem that it is difficult to obtain high-quality graphene film with a controllable number of layers, and achieve the effect suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

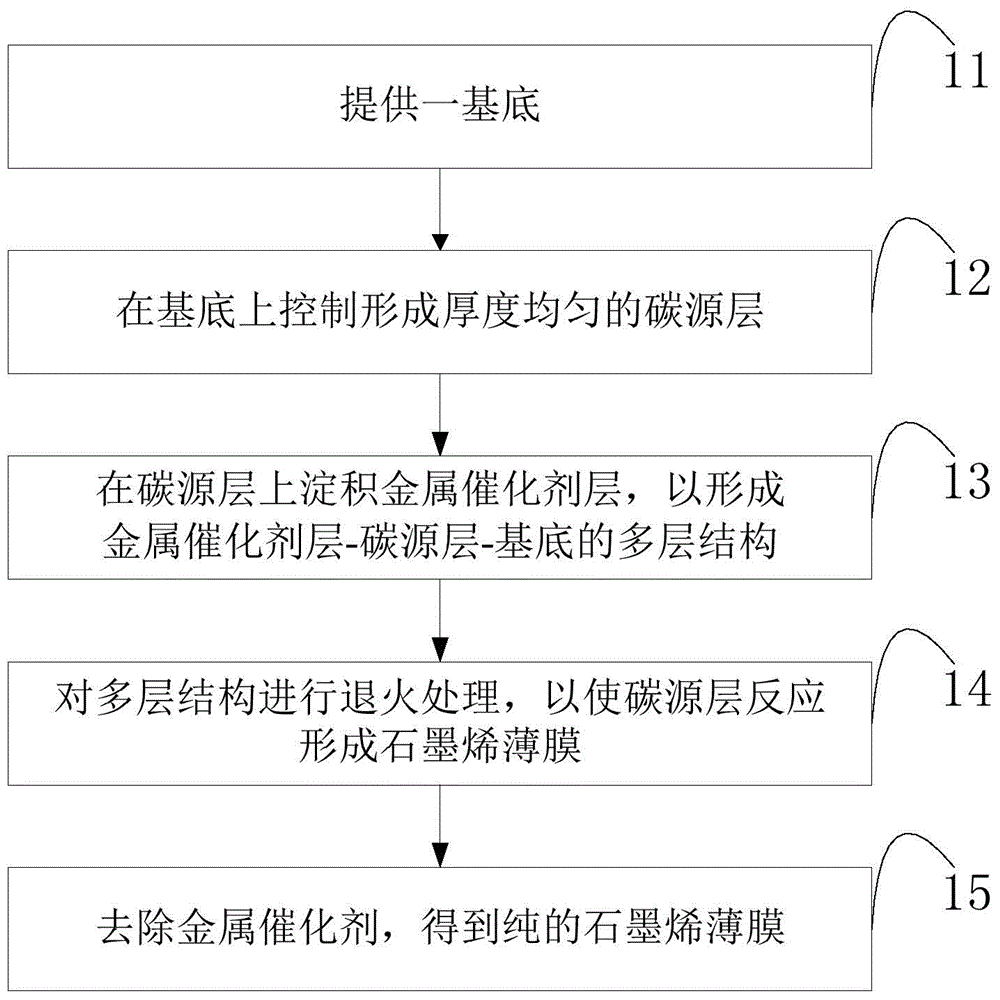

[0028] The following is attached figure 1 The preparation method of the graphene thin film of the present invention is described in further detail with specific examples. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0029] see figure 1 , the preparation method of the graphene film of the present embodiment comprises the following steps:

[0030] Step 11: providing a substrate;

[0031] Here, the carbon concentration of the provided substrate is required to be extremely low. If the carbon concentration in the substrate is high, it will lead to the precipitation of carbon in the substrate during the subsequent annealing treatment, thereby destroying the precisely controlled thickness and uniformity of the carbon source layer. sex. The carbon concentration of the substrate is lower than 0.5ppma; the substrate c...

Embodiment 2

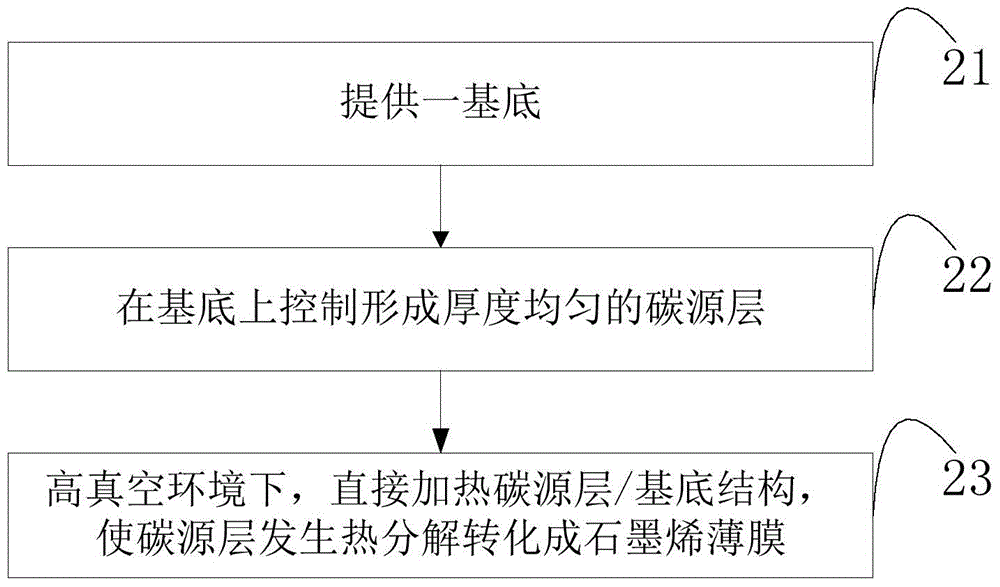

[0041] The preparation steps of the graphene thin film of the present embodiment two are substantially the same as those in the first embodiment, the difference is that in the second embodiment, the metal catalyst is not used to form the graphene thin film, but in a high vacuum environment, the carbon The source layer is directly pyrolyzed to obtain a graphene film; thus, the material of the carbon source layer in the second embodiment must have high temperature pyrolysis characteristics, and silicon carbide is used here. Specifically, see figure 2 , the graphene preparation method of the present embodiment two specifically comprises the following steps:

[0042] Step 21, provide a base; Here, adopt SiO 2 / Si substrate; this step can refer to the specific description of step 11 in embodiment one;

[0043] Step 22, control and form a carbon source layer with a uniform thickness on the substrate; here it is a silicon carbide layer with a thickness of 3nm; thereby forming a si...

Embodiment 3

[0046] The preparation step of the graphene thin film of present embodiment three is identical with embodiment one, and difference is: in the present embodiment, adopt Langmuir-Blodgett (LB) film method that liquid carbon source toluene molecule is evenly coated on the substrate, Form a toluene molecular film / substrate structure, and then use the same steps S13-S15 as in Example 1 to form a graphene film / substrate structure.

[0047] In summary, the preparation method of the graphene thin film of the present invention first controls the formation of a carbon source layer with uniform thickness on the substrate, and then the carbon source layer is heated and reacts to form a graphene thin film. In this way, by precisely controlling the uniformity of the carbon source layer and thickness, can precisely control the uniformity and thickness of the graphene film; at the same time, the graphene preparation method of the present invention can obtain high-quality graphene film, which can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com