Chemical agent and process for treating wastewater containing thallium and heavy metals

A technology for heavy metals and chemicals, applied in the field of chemicals and processes for treating wastewater containing thallium and heavy metals, can solve the problems of complex treatment process, incomplete treatment and high cost, and achieve the effects of simple process, saving factory investment and fast processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Comprehensive Wastewater Treatment Containing Thallium

[0028] A compound agent (RX-1 self-defined code) for treating thallium-containing and heavy metal wastewater of the present invention mainly consists of 7.8kg of 4-methyl-dimercaptobutane disodium, 32kg of 5,8-diethyl - 7-hydroxyl-6-dodecanone oxime, 20.2kg of 5-dodecyl salicylaldoxime and 40kg of dibutyl sodium dithiophosphate are placed in a mixing reactor and mixed uniformly.

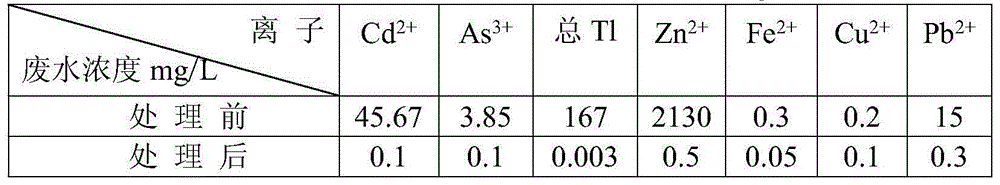

[0029] Use inorganic thallium, Mn, Zn, Cu, Hg, Cd, Pb, Cr, Ni salts to prepare wastewater samples containing thallium and various heavy metal ions as shown in Table 1, take 100ml of water samples, and place them in a beaker stand-by.

[0030] After adding 100mL of 2% RX-1 pharmaceutical aqueous solution to the waste water sample to be used, after stirring for 5 minutes, a large amount of metal complex precipitates will be produced, then add 8ml, 1% concentration of magnesium hydroxide inorganic flocculant, and stir for 5 minu...

Embodiment 2

[0034] Embodiment 2: zinc metallurgical wastewater treatment

[0035] A compound agent (RX-2 self-defined code) for treating thallium-containing and heavy metal wastewater of the present invention mainly consists of 4kg dimercaptopropanol, 31kg 2-hydroxy-5-nonylbenzophenone oxime, 18kg dipropylene Potassium dithiophosphate and 47kg sodium diisobutyl dithiophosphate are placed in a mixer and mixed uniformly.

[0036] to 100m 3 Add 10m3 of the solution of RX-2 composite agent with a mass concentration of 3% to the waste water (zinc metallurgy waste water, washing water or filter press water, and the thallium and heavy metals contained in it are shown in Table 2 below), and a large amount of metals will be produced after stirring for 5 minutes. Complex precipitation, then add 1.5% magnesium hydroxide inorganic flocculant 0.5m 3 , stirred for 5 minutes, and finally added polyacrylamide 0.5% flocculant 0.2m 3 , and stir for 5 minutes. The sediment was removed by filtration, and...

Embodiment 3

[0040] Example 3: Treatment of metallurgical thallium-containing wastewater

[0041] A compound agent (RX-3 self-defined code) for treating thallium-containing and heavy metal wastewater of the present invention mainly consists of 25kg of 2-methyl-dimercaptobutane disodium, 28kg of 2-hydroxy-4-octyl Oxybenzophenone oxime and 47kg sodium diisopropyl dithiophosphate are placed in a mixer and mixed uniformly to make.

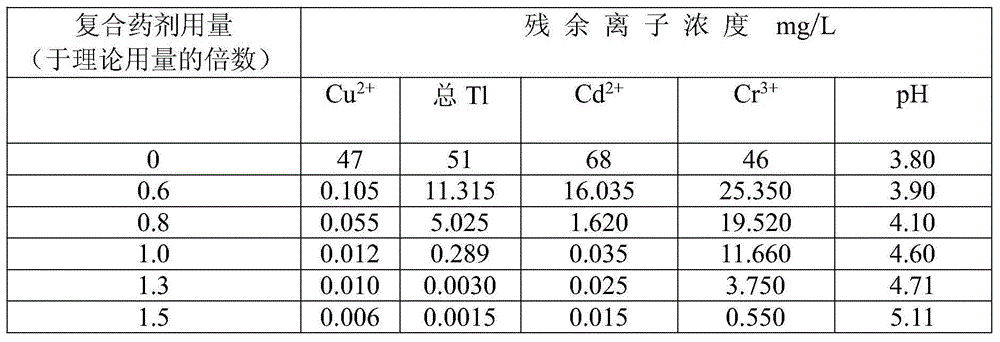

[0042] For the metallurgical wastewater in this example, different doses of composite agents (RX-3) were added, and the dosage was between 0.5 and 1.5 times the theoretical amount of heavy metals, and the relationship test between the addition and the treatment effect of heavy metals was carried out. The results As shown in Table 3 below.

[0043] Table 3: The effect of the addition amount of the compound agent on the treatment effect

[0044]

[0045] It can be seen from Table 3 that the removal rate increases with the increase of the amount of compound agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com