External wall fireproof thermal-insulation plate prepared by using slag cotton

A technology of fire prevention and heat preservation, slag wool, which is applied in the direction of glass manufacturing equipment, manufacturing tools, etc., to achieve the effect of reducing power consumption, low production cost, and light density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

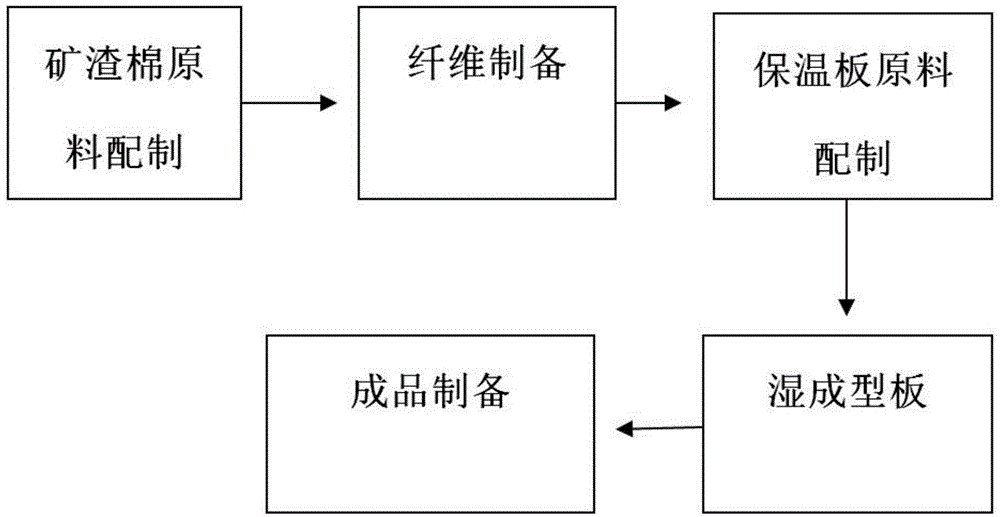

[0029] A kind of production method of the building external wall fireproof insulation material prepared with slag wool:

[0030] (1) Raw material preparation of slag wool: mix blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, wollastonite and melt them into a liquid mixture;

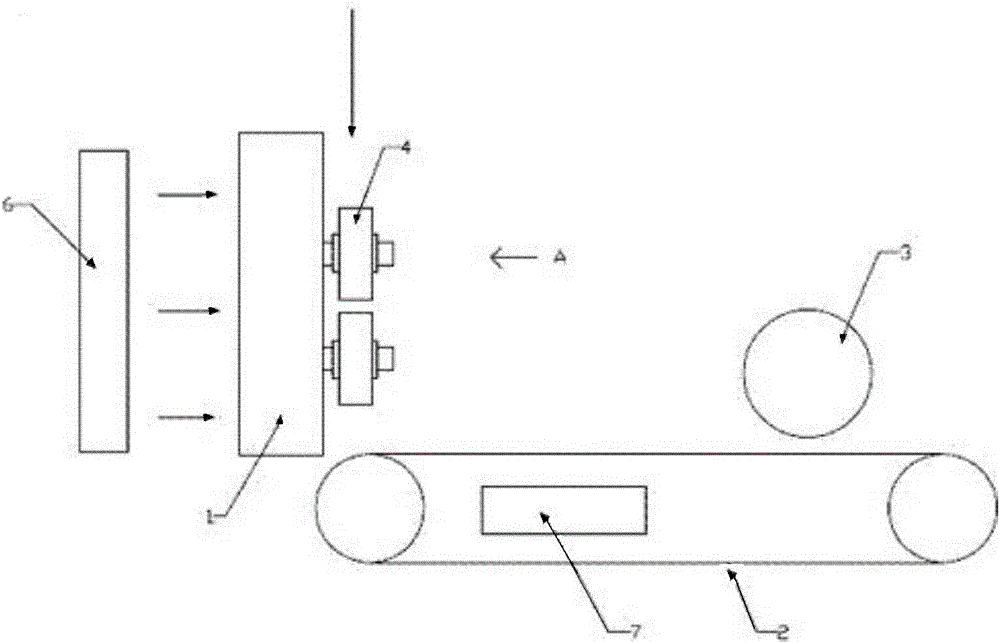

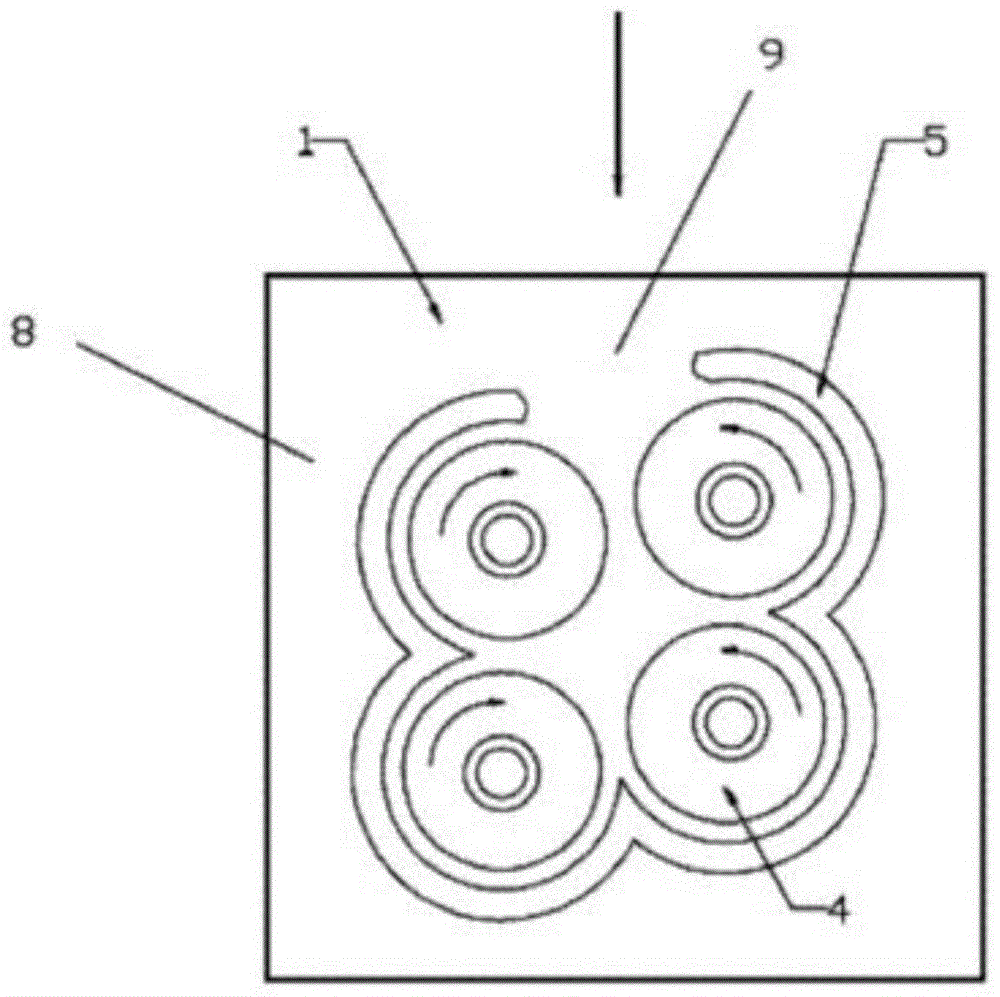

[0031] (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into filamentous filaments under the action of centrifugal throwing and air cooling, and the filaments are collected and formed under the action of the blower. ;

[0032] (3) Preparation of insulation material raw materials: 59% of slag cotton, 6% of polycrystalline zirconia fiber, 15% of desulfurized gypsum, 10% of fly ash, and 10% of 425# cement prepared in the above steps;

[0033] (4) Preparation of wet forming board: put slag wool into the cotton beating pool and mix it with water at a mass ratio of 1:1.2 to make slag cotton ...

Embodiment 2

[0038] A kind of production method of the building external wall fireproof insulation material prepared with slag wool:

[0039] (1) Raw material preparation of slag wool: mix blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, wollastonite and melt them into a liquid mixture;

[0040] (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into filamentous filaments under the action of centrifugal throwing and air cooling, and the filaments are collected and formed under the action of the blower. ;

[0041] (3) Preparation of raw materials for thermal insulation materials: 55% slag cotton, 3% polycrystalline zirconia fiber, 17% desulfurized gypsum, 10% fly ash, 15% 425# cement;

[0042] (4) Preparation of wet forming board: put slag wool into the cotton beating pool and mix it with water at a mass ratio of 1:1.2 to make slag cotton pulp, then mix polycrystalline zir...

Embodiment 3

[0047] A kind of production method of the building external wall fireproof insulation material prepared with slag wool:

[0048] (1) Raw material preparation of slag wool: mix blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, wollastonite and melt them into a liquid mixture;

[0049] (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into filamentous filaments under the action of centrifugal throwing and air cooling, and the filaments are collected and formed under the action of the blower. ;

[0050] (3) Preparation of insulation material raw materials: 60% of slag cotton, 4% of polycrystalline zirconia fiber, 15% of desulfurized gypsum, 10% of fly ash, and 11% of 425# cement prepared in the above steps;

[0051] (4) Preparation of wet forming board: put slag wool into the cotton beating pool and mix it with water at a mass ratio of 1:1.2 to make slag cotton ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com