Unsaturated polyester and fiber reinforced composite material thereof based on environment-friendly reactive solvent

A reactive solvent, environmentally friendly technology, used in the field of fiber-reinforced resin composite materials, can solve problems such as air pollution, and achieve high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Raw materials: raw bamboo fiber (average length 22.81mm, average width 150μm) was provided by Fujian Haibosi Chemical Technology Co., Ltd.; propylene glycol (PG) was purchased from SAFC Company of the United States; isophthalic acid (IPA) was purchased from Sigma-Aldrich Company of the United States ; Fumaric acid (FA) was purchased from Fluka Analytical Company of the United States; Butyl titanate (TB) was purchased from Fluka Analytical Company of the United States; 4-methoxyphenol (MP) was purchased from Sigma-Aldrich Company of the United States; N- Vinylpyrrolidone (NVP) was purchased from Sigma-Aldrich, USA; the initiator was tert-butyl peroxybenzoate (TBPB), purchased from Sigma-Aldrich, USA; ethyl acetate was purchased from EMD, USA.

[0019] UPE composites with bamboo fiber reinforced NVP as reactive solvent:

[0020] The solid UPE resin powder, NVP and initiator are mixed according to a certain mass ratio to obtain a styrene-free UPE resin mixed liquid. T...

Embodiment 2

[0024] Raw materials: raw bamboo fiber (average length 22.81mm, average width 150μm) was provided by Fujian Haibosi Chemical Technology Co., Ltd.; propylene glycol (PG) was purchased from SAFC Company of the United States; isophthalic acid (IPA) was purchased from Sigma-Aldrich Company of the United States ; Fumaric acid (FA) was purchased from Fluka Analytical Company of the United States; Butyl titanate (TB) was purchased from Fluka Analytical Company of the United States; 4-methoxyphenol (MP) was purchased from Sigma-Aldrich Company of the United States; N- Vinylpyrrolidone (NVP) was purchased from Sigma-Aldrich, USA; the initiator was tert-butyl peroxybenzoate (TBPB), purchased from Sigma-Aldrich, USA; ethyl acetate was purchased from EMD, USA.

[0025] UPE composites with bamboo fiber reinforced NVP as reactive solvent:

[0026] The solid UPE resin, NVP and initiator are mixed according to a certain mass ratio to obtain a styrene-free UPE resin mixed solution. The mixed ...

PUM

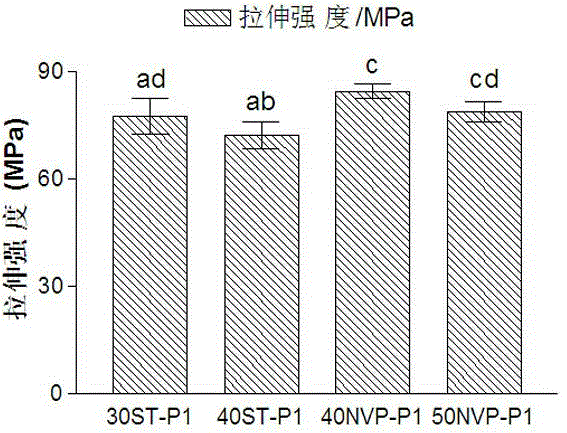

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com