Water-based environment-protective resin, preparation method and application

An environmentally friendly resin, water-based technology, used in special paper, coatings, paper coatings, etc., can solve problems such as poor processing performance, and achieve the effects of easy access, good scrubability and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

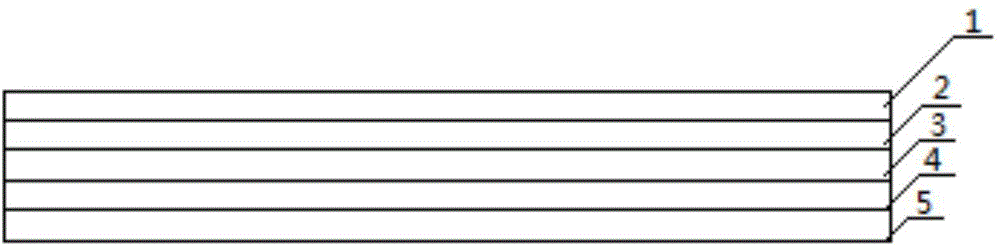

Image

Examples

Embodiment 1

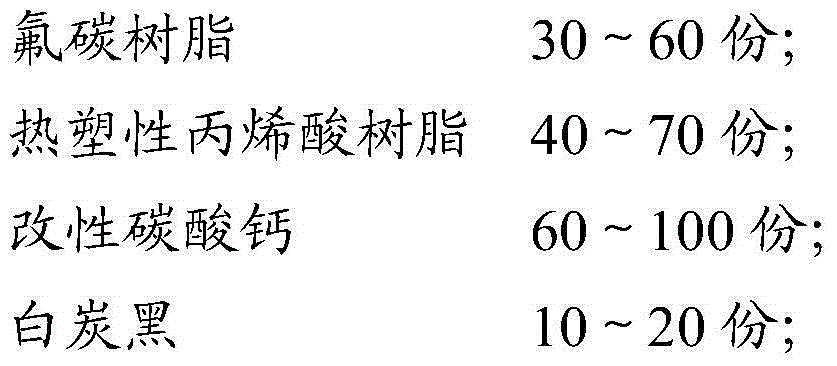

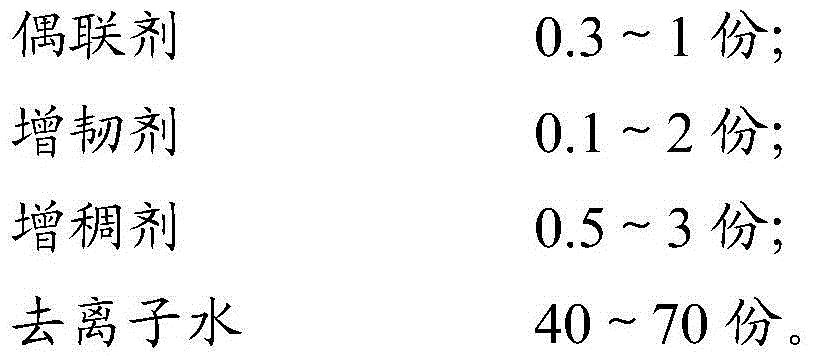

[0029] A kind of water-based environment-friendly resin described in the embodiment is made of the following components in parts by weight:

[0030]

[0031] Among them, the thickener is one of cellulose thickener and polyurethane thickener; the toughener is one of polyvinyl alcohol and polyvinyl butyral; the coupling agent is vinyl triethyl Any one or more of oxysilane, methacryloxypropyltrimethoxysilane, and ethylenediaminopropyltriethoxysilane.

[0032] A kind of preparation method of water-based environment-friendly resin described in the embodiment of the present invention, comprises the following steps:

[0033] 1) Mix and stir the fluorocarbon resin, thermoplastic acrylic resin, and coupling agent in said parts by weight to form a mixture A; wherein, the solid content of the fluorocarbon resin used in this step is ≥50%, and the fluorine content is ≥20% .

[0034] 2) the modified calcium carbonate of described parts by weight, white carbon black and the described mi...

Embodiment 2

[0038] A kind of water-based environmental protection resin described in the embodiment of the present invention is made of the following components in parts by weight:

[0039]

[0040]

[0041] Among them, the thickener is one of cellulose thickener and polyurethane thickener; the toughener is one of polyvinyl alcohol and polyvinyl butyral; the coupling agent is vinyl triethyl Any one or more of oxysilane, methacryloxypropyltrimethoxysilane, and ethylenediaminopropyltriethoxysilane.

[0042] A kind of preparation method of water-based environment-friendly resin described in the embodiment of the present invention, comprises the following steps:

[0043] 1) Mix and stir the fluorocarbon resin, thermoplastic acrylic resin, and coupling agent in said parts by weight to form a mixture A; wherein, the solid content of the fluorocarbon resin used in this step is ≥50%, and the fluorine content is ≥20% .

[0044] 2) the modified calcium carbonate of described parts by weight, ...

Embodiment 3

[0048] A kind of water-based environmental protection resin described in the embodiment of the present invention is made of the following components in parts by weight:

[0049]

[0050] Among them, the thickener is one of cellulose thickener and polyurethane thickener; the toughener is one of polyvinyl alcohol and polyvinyl butyral; the coupling agent is vinyl triethyl Any one or more of oxysilane, methacryloxypropyltrimethoxysilane, and ethylenediaminopropyltriethoxysilane.

[0051] A kind of preparation method of water-based environment-friendly resin described in the embodiment of the present invention, comprises the following steps:

[0052] 1) Weigh each raw material according to the above weight parts, weigh the fluorocarbon resin, thermoplastic acrylic resin, and coupling agent, and pour them into the reaction kettle to mix and stir evenly; the solid content of the fluorocarbon resin used in this step is ≥50%, Fluorine content ≥ 20%.

[0053] 2) Add the modified c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com