Semi-coke mixed burning method

A blue charcoal and a part of the technology, applied in the field of blue charcoal blending, can solve the problem of lack of extensive research in application, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Process the semi-coke through a crusher and a screening machine to obtain coal particles with a particle size of ≤50mm;

[0020] 2) Process the PCI coal through a crusher and a screening machine to obtain a coal particle size ≤ 50mm;

[0021] 3) Inject semi-coke and PCI coal into the hopper at a mass ratio of 50:50, and the hopper is divided into two parts by a partition, one part is used for injecting semi-coke, and the other part is used for injecting PCI;

[0022] 4) Mix the semi-coke and PCI coal in the hopper into the vibrating hopper below the hopper to obtain mixed pulverized coal;

[0023] 5) Put the mixed coal powder mixed in step 4 into the gasifier at 1100°C for reaction to generate syngas for indirect coal liquefaction.

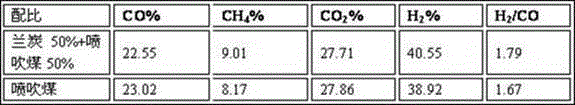

[0024] The hydrogen-to-carbon ratio of the syngas is controlled at H 2 / CO>1.7. The comparison of the obtained coal synthesis gas with the synthesis gas obtained using PCI is shown in Table 1.

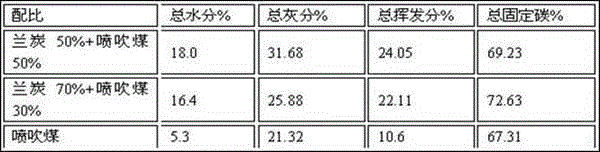

[0025] Table 1 The main components of ...

Embodiment 2

[0028] 1) Process the semi-coke through a crusher and a screening machine to obtain coal particles with a particle size of ≤50mm;

[0029] 2) Process the PCI coal through a crusher and a screening machine to obtain a coal particle size ≤ 50mm;

[0030] 3) Inject semi-coke and PCI coal into the hopper at a mass ratio of 70:30, and the hopper is divided into two parts by a partition, one part is used for injecting semi-coke, and the other part is used for injecting PCI;

[0031] 4) Mix the semi-coke and PCI coal in the hopper into the vibrating hopper below the hopper to obtain mixed pulverized coal;

[0032] 5) Put the mixed coal powder mixed in step 4 into the gasifier at 1100°C for reaction to generate syngas for indirect coal liquefaction.

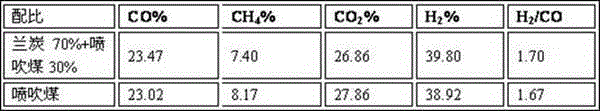

[0033] The hydrogen-to-carbon ratio of the syngas is controlled at H 2 / CO>1.7. The comparison of the obtained coal synthesis gas with the synthesis gas obtained using PCI is shown in Table 2.

[0034] Table 2 The main components of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com