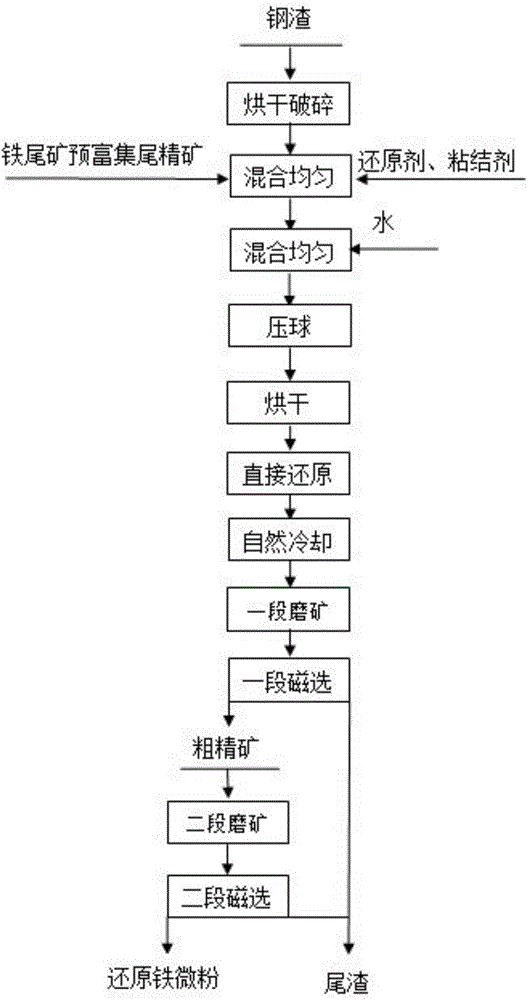

Method for reducing iron tailings and enriching tail concentrate by taking steel slag as additive

A technology for pre-enrichment and reduction of iron is applied in the field of comprehensive utilization of resources to achieve the effects of quality reduction, energy saving and simple process method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

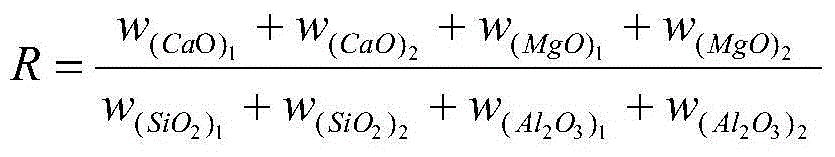

[0024] A steel slag contains 12.22% of silicon dioxide, 35.82% of calcium oxide, 11.00% of magnesium oxide, 6.84% of aluminum oxide and 19.37% of total iron. The steel slag is dried and crushed, so that the particle size of the crushed steel slag is -2mm, wherein the steel slag with a particle size of -1mm accounts for 92%, and the steel slag with a particle size of -0.1mm accounts for 56%. Using iron tailings pre-enriched tailings concentrate as raw material, adding steel slag with a quaternary alkalinity of 0.4 as an additive, 15% bituminous coal as a reducing agent, and 0.4% sodium carboxymethylcellulose as a binder, and then Mix evenly to make mixed raw meal; add 7% water to the mixed raw meal and mix evenly again, and then press balls in the briquetting equipment to make green pellets; dry the made green pellets, and then Put it into a reducing atmosphere furnace for rapid reduction, the reduction temperature is 1350°C, and the reduction time is 30 minutes. The product ob...

Embodiment 2

[0026] A steel slag contains 11.60% silicon dioxide, 41.80% calcium oxide, 10.08% magnesium oxide, 1.43% aluminum oxide and 22.08% total iron. The steel slag is dried and crushed, so that the particle size of the crushed steel slag is -2mm, wherein the steel slag with a particle size of -1mm accounts for 92%, and the steel slag with a particle size of -0.1mm accounts for 56%. Using iron tailings pre-enriched tailings concentrate as raw material, adding steel slag with a quaternary alkalinity of 0.3 as an auxiliary agent, 25% bituminous coal as a reducing agent, and 0.5% sodium carboxymethylcellulose as a binder, and then Mix evenly to make mixed raw meal; add 8% water to the mixed raw meal and mix evenly again, and then press balls in the briquetting equipment to make green pellets; dry the made green pellets, and then Put it into a reducing atmosphere furnace for rapid reduction, the reduction temperature is 1350°C, and the reduction time is 40 minutes. The product obtained a...

Embodiment 3

[0028]A steel slag contains 12.22% of silicon dioxide, 35.82% of calcium oxide, 11.00% of magnesium oxide, 6.84% of aluminum oxide and 19.37% of total iron. The steel slag is dried and crushed, so that the particle size of the crushed steel slag is -2mm, wherein the steel slag with a particle size of -1mm accounts for 92%, and the steel slag with a particle size of -0.1mm accounts for 56%. Using iron tailings pre-enriched tailings concentrate as raw material, adding steel slag with a quaternary alkalinity of 0.4 as an auxiliary agent, 25% bituminous coal as a reducing agent, and 0.5% sodium carboxymethylcellulose as a binder, and then Mix evenly to make mixed raw meal; add 9% water into the mixed raw meal and mix evenly again, and then press balls in the briquetting equipment to make green pellets; dry the made green pellets, and then Put it into a reducing atmosphere furnace for rapid reduction, the reduction temperature is 1325°C, and the reduction time is 40 minutes. The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com