Hand-push type power drive steel brush de-icing machine

A power-driven, deicer technology, applied in cleaning methods, snow surface cleaning, construction, etc., can solve the problems of laboriousness, low operation efficiency, and high energy consumption by thermal deicing, so as to reduce the intensity of manual work and improve the The effect of working efficiency and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

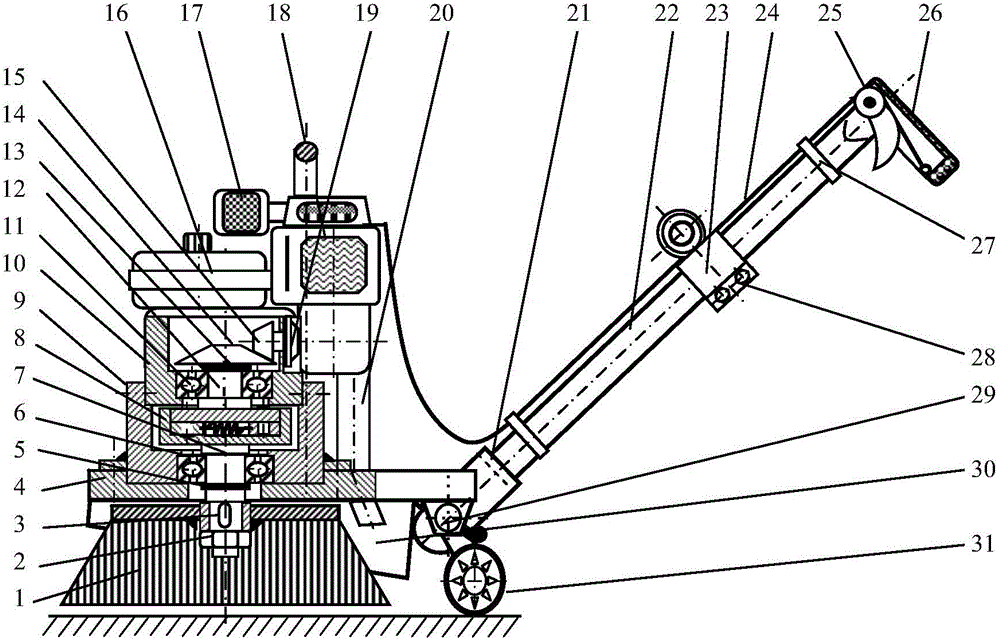

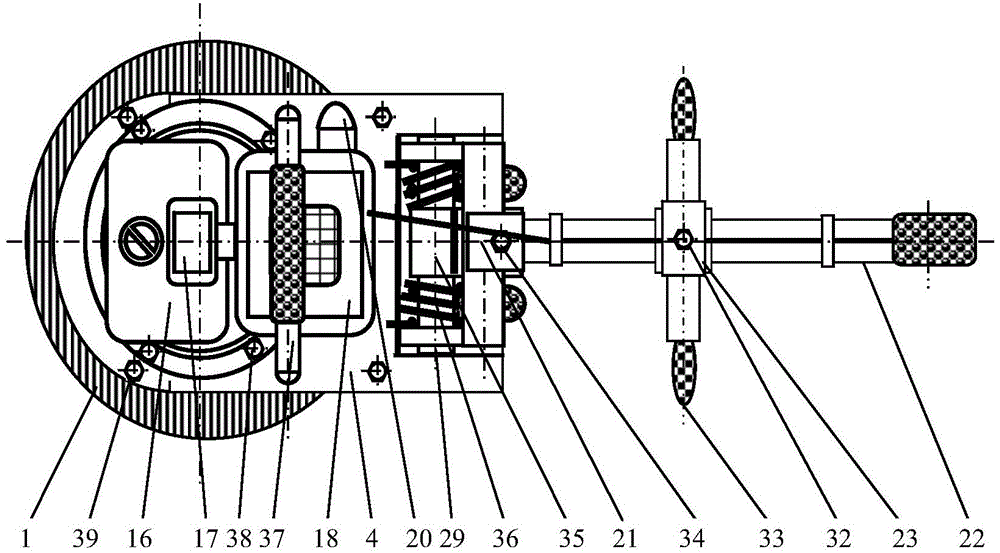

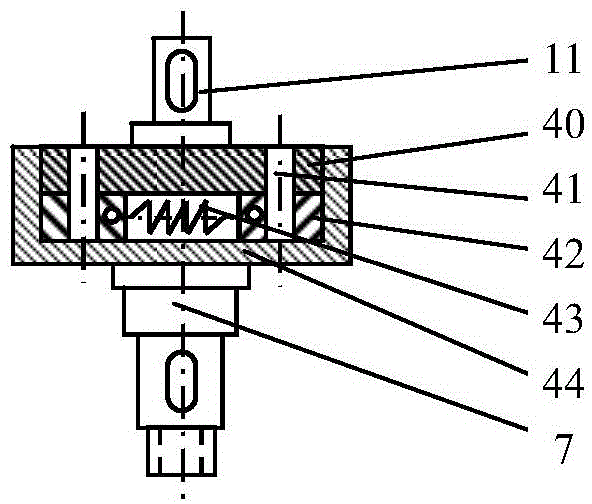

[0016] like figure 1 As shown, in the structure of the hand-push power-driven steel brush deicer described in the present invention, a small internal combustion engine 18, a fuel tank 16, an air filter 17 and an exhaust pipe 20 form a power unit, and the flange 19 is formed by a bolt Connected and installed on the casing of the reducer 10; the power output part of the small internal combustion engine 18 is mechanically connected with the drive gear 15 of the reducer, and the drive gear 15 of the reducer and the driven gear 14 of the reducer transmit power in the form of meshing transmission; The inner ring of the bearing 11 is installed on the clutch input shaft 12, and it is positioned by the circlip 13, and the outer ring of the bearing 11 is installed in the bearing seat of the reducer 10 box; the lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com