Tracer agent spraying system applied for visual engine test

A technology of injection system and tracer, which is applied in the direction of engine testing, engine components, machine/engine, etc., can solve the problems of large gaps and errors, and the inability to fully and effectively calibrate the engine measurement objects, so as to achieve optimal mixing and save experiments The effect of prep time, good dispersion and proportioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

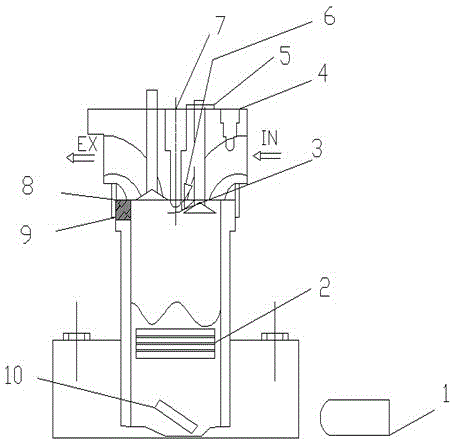

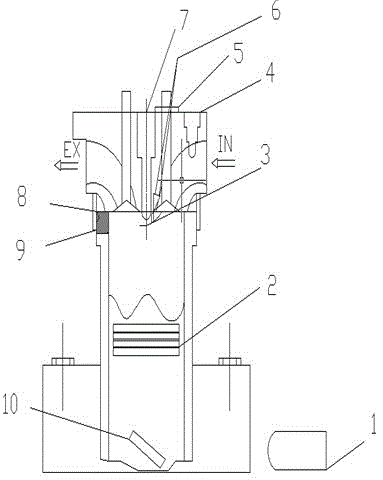

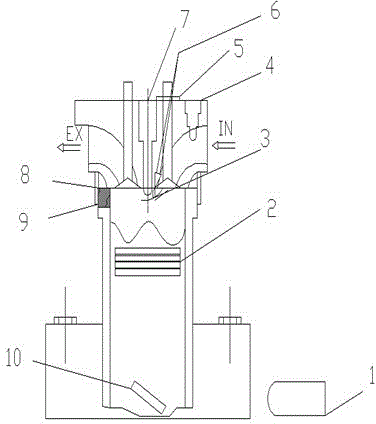

[0020] (1) Use conventional 3-pentanone with a volume fraction of 10% (Scheme 1), or acetone with a volume fraction of 10% (Scheme 2) and 3-hexanone with a volume fraction of 9% and a volume fraction of 1% 3-Pentanone was mixed in a ratio of 4:1 by volume (Scheme 3) in a tracer proportioning scheme separately placed in the tracer injection valve.

[0021] (2) Use commonly used isooctane or n-pentane with weak fluorescent effect as an alternative fuel, control it through the injection system, place it in the fuel injector, turn on the laser, and adjust the angle to 15° to the axis of the engine cylinder head 65°.

[0022] (3) The piston moves from the top dead center to the bottom dead center driven by the crankshaft; at this time, the intake valve opens, the exhaust valve closes, and the crankshaft rotates 180°. At this time, the tracer and air quickly mix and enter the cylinder. It is further mixed with alternative fuels in the cylinder to form a combustible mixture.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com