Method for improvingthermal stability of test strips for detecting peroxide value of cooking oil

A technology of oil peroxide value and thermal stability, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problems of easy failure, inaccurate results, and long reaction time. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

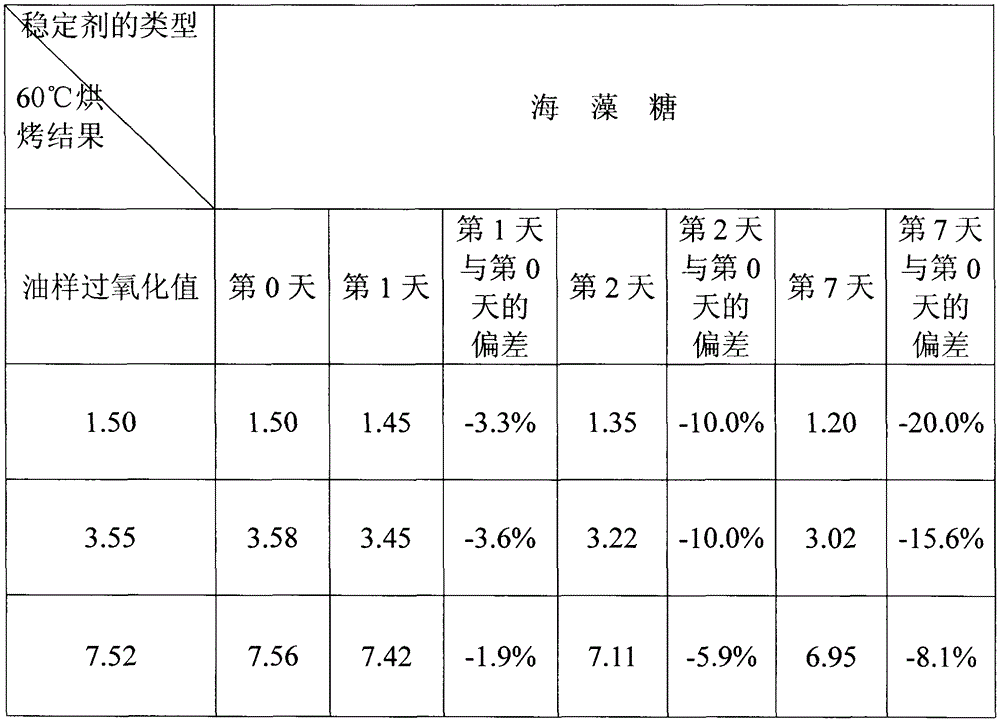

[0018] The stabilizer of embodiment 1 reagent composition only has the preparation of the test paper block of trehalose

[0019] 1. Dissolve 100g of citric acid buffer reagent, 1.6g of horseradish peroxidase, 2.8g of surfactant, 12g of background material and 100g of trehalose in 1000mL of deionized water in sequence. Immerse the filter paper in the solution, take it out after 1 minute, and dry it at 60°C; then dissolve 15g of the color developer and 10g of the reaction accelerator in 1000mL of absolute ethanol, soak the filter paper in the solution for 1 minute, take it out and dry it at 60°C Dry at ℃, cut into 5×5mm square test paper pieces and pack them in airtight vacuum-packed aluminum foil bags for later use. At the same time, a small amount of test paper pieces were sealed and placed in an oven at 60°C for continuous baking for 1 day, 2 days, and 7 days respectively.

[0020] 2. Use a straw to drop a drop of the oil sample to be tested on the test paper block. After 12...

Embodiment 2

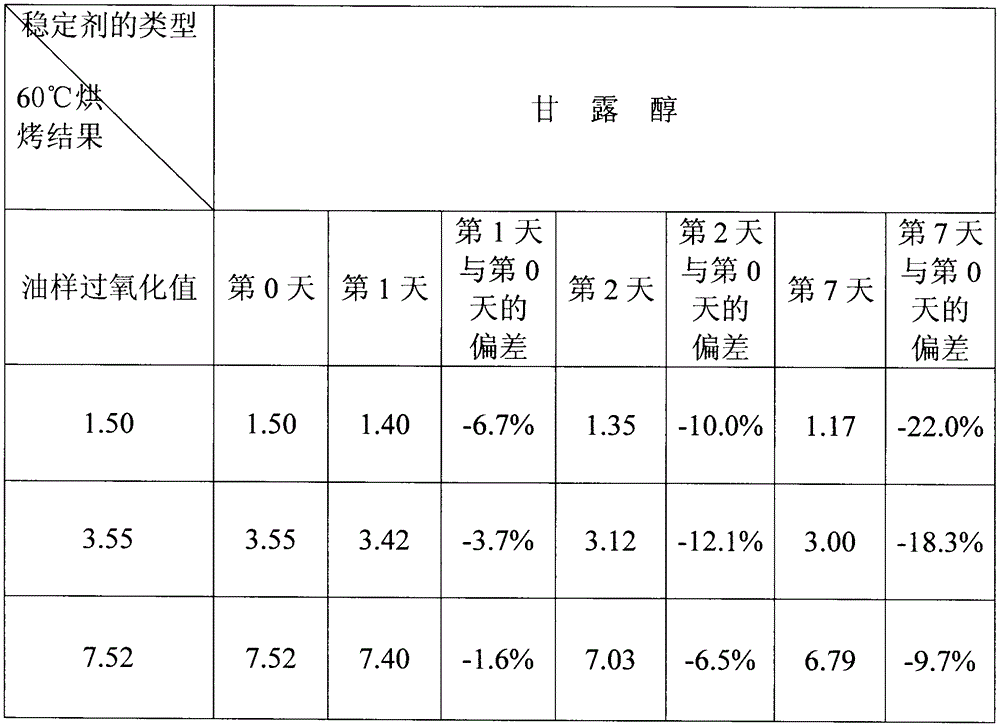

[0023] The stabilizer of embodiment 2 reagent composition has only the preparation of the test paper block of mannitol

[0024] 1. Dissolve 100g of citric acid buffer reagent, 1.6g of horseradish peroxidase, 2.8g of surfactant, 12g of background material and 100g of mannitol in 1000mL of deionized water in sequence. Immerse the filter paper in the solution, take it out after 1 minute, and dry it at 60°C; then dissolve 15g of the color developer and 10g of the reaction accelerator in 1000mL of absolute ethanol, soak the filter paper in the solution for 1 minute, take it out and dry it at 60°C Dry at ℃, cut into 5×5mm square test paper pieces and pack them in airtight vacuum-packed aluminum foil bags for later use. At the same time, a small amount of test paper pieces were sealed and placed in an oven at 60°C for continuous baking for 1 day, 2 days, and 7 days respectively.

[0025] 2. Use a straw to drop a drop of the oil sample to be tested on the test paper block. After 120 ...

Embodiment 3

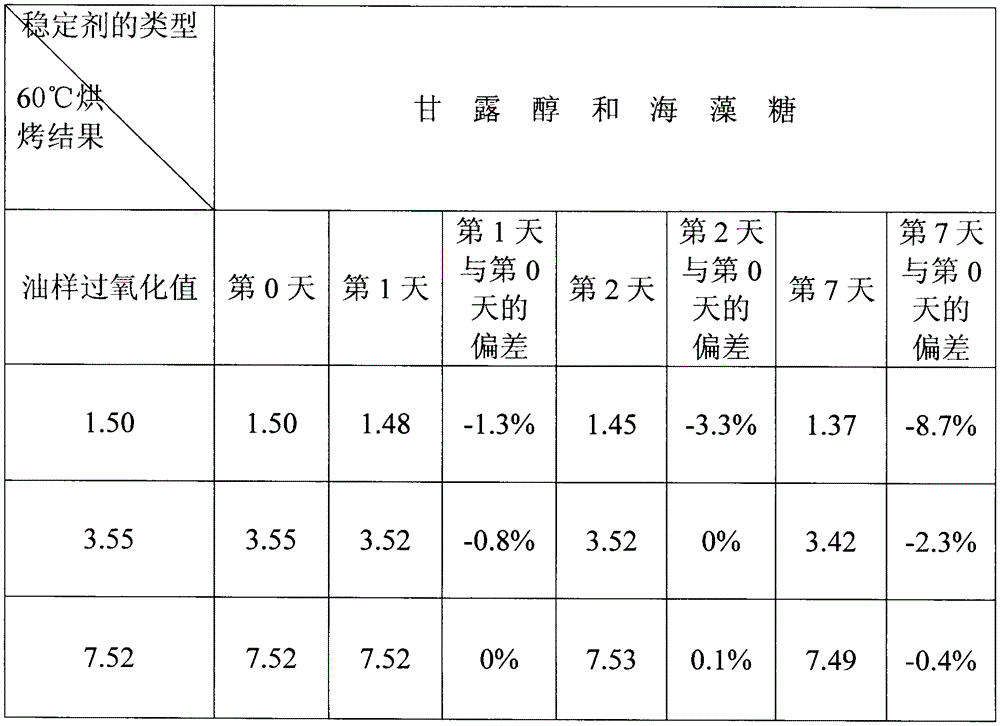

[0028] The stabilizer of embodiment 3 reagent composition is the preparation of the mixture test paper block of mannitol and trehalose

[0029] 1. Dissolve 100g of citric acid buffer reagent, 1.6g of horseradish peroxidase, 2.8g of surfactant, 12g of base color material and 100g of a mixture of mannitol and trehalose in 1000mL of deionized water in sequence. Immerse the filter paper in the solution, take it out after 1 minute, and dry it at 60°C; then dissolve 15g of the color developer and 10g of the reaction accelerator in 1000mL of absolute ethanol, soak the filter paper in the solution for 1 minute, take it out and dry it at 60°C Dry at ℃, cut into 5×5mm square test paper pieces and pack them in airtight vacuum-packed aluminum foil bags for later use. At the same time, a small amount of test paper pieces were sealed and placed in an oven at 60°C for continuous baking for 1 day, 2 days, and 7 days respectively.

[0030] 2. Use a straw to drop a drop of the oil sample to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com