Scanning type metal surface imaging and component analyzing device

A metal surface and component analysis technology, which is applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., to achieve reasonable structure design and improve analysis accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

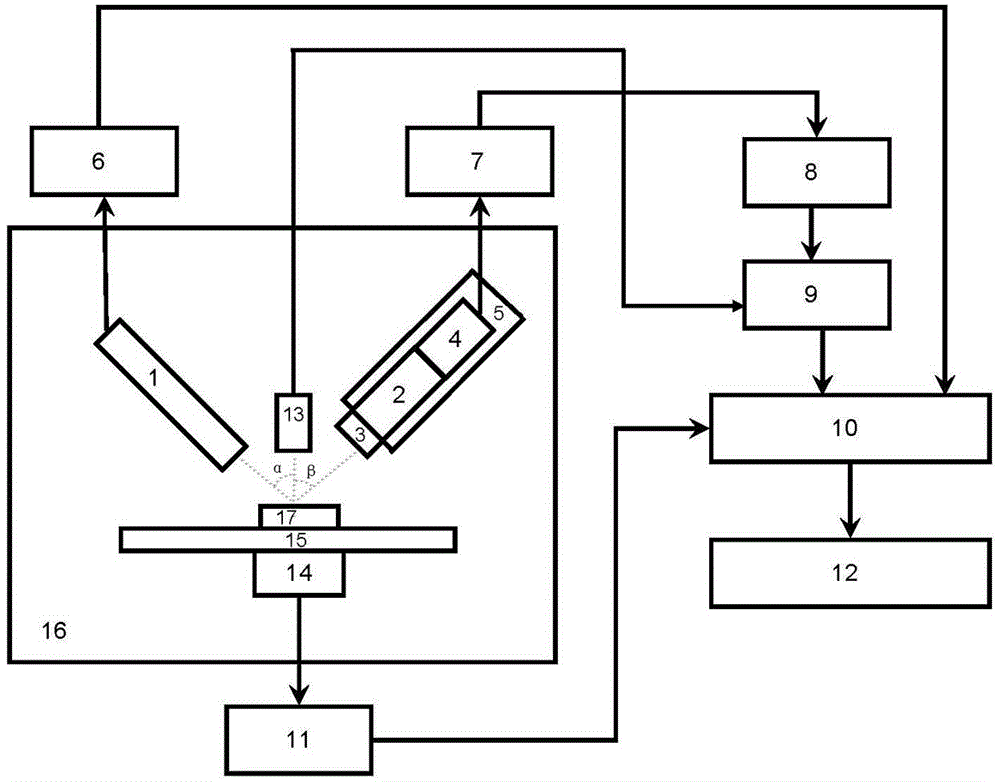

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] refer to figure 1 , in the scanning metal surface imaging and component analysis device of the present invention, X-ray tube 1 generates incident X-rays, and its energy is determined by high-voltage control system 6; X-ray tube 1, X fluorescence probe 2, collimator 3, position sensitive The photomultiplier tube 4 , the detector package 5 , and the laser range finder 13 are all arranged in the shielding body 16 and above the sample stage 15 . The X-ray tube 1 and the X-fluorescent probe 2 are reflectively arranged, the laser rangefinder 13 is arranged directly above the sample 17, and the X-ray tube 1 and the X-fluorescent probe 2 are symmetrically arranged on both sides of the laser rangefinder 13 respectively. The angle α between the surface normal of tube 1 and sample 17 is 67.5°, the angle β betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com