Biocompatible miniature frictional generator

A biocompatible, triboelectric generator technology, applied in triboelectric generators and other directions, can solve the problem that batteries cannot provide permanent electrical energy, and achieve the effects of simple structure, promotion of cell growth, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

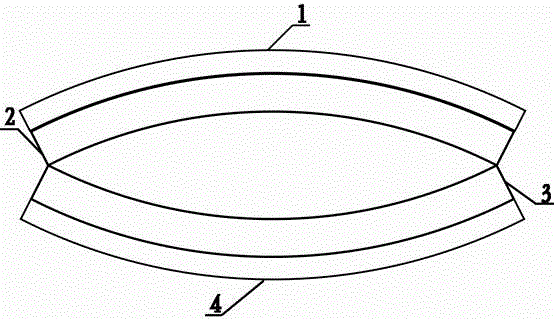

[0021] A biocompatible miniature triboelectric generator, such as figure 1 As shown, it is composed of nylon 66 coating layer 1 on the upper plate, poly-L-lactic acid polymer friction layer 2 on the upper plate, ethyl cellulose friction layer 3 on the lower plate, and nylon 66 coating layer 4 on the lower plate. The plate material is a plate formed by insulating poly-L-lactic acid that is easy to obtain electrons, and the lower plate is a plate formed by insulating ethyl cellulose that is easy to lose electrons. The contact interface of the upper and lower plates is made with patterns of different shapes , The upper and lower plates form an arc-shaped space in close contact with each other according to the concave and convex, and are encapsulated with biocompatible nylon 66 film.

[0022] The molecular weight of the upper plate material poly-L-lactic acid is 150,000, the thickness of the upper plate is 4mm, the width is 60mm, and the length is 70mm. It is prepared by a film sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com