Fiber-reinforced hydrogel composites and methods of forming fiber-reinforced hydrogel composites

A composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced hydrogel composite materials to form fiber-reinforced hydrogel composite materials, can solve problems such as blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0079] Other implementations are within the scope of the claims and non-limiting examples. In addition, where features or aspects of the invention are described in terms of Markush groups, those skilled in the art will recognize that the invention is also thereby described in terms of any individual member or subgroup of members of the Markush group.

[0080] Example part

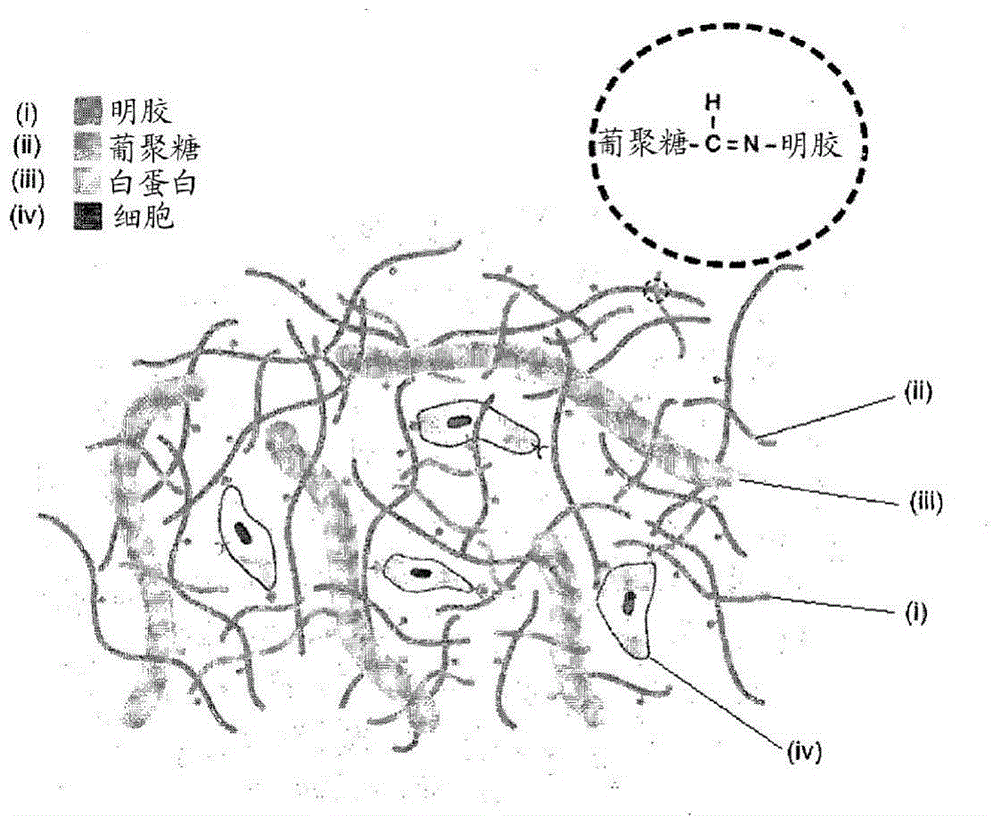

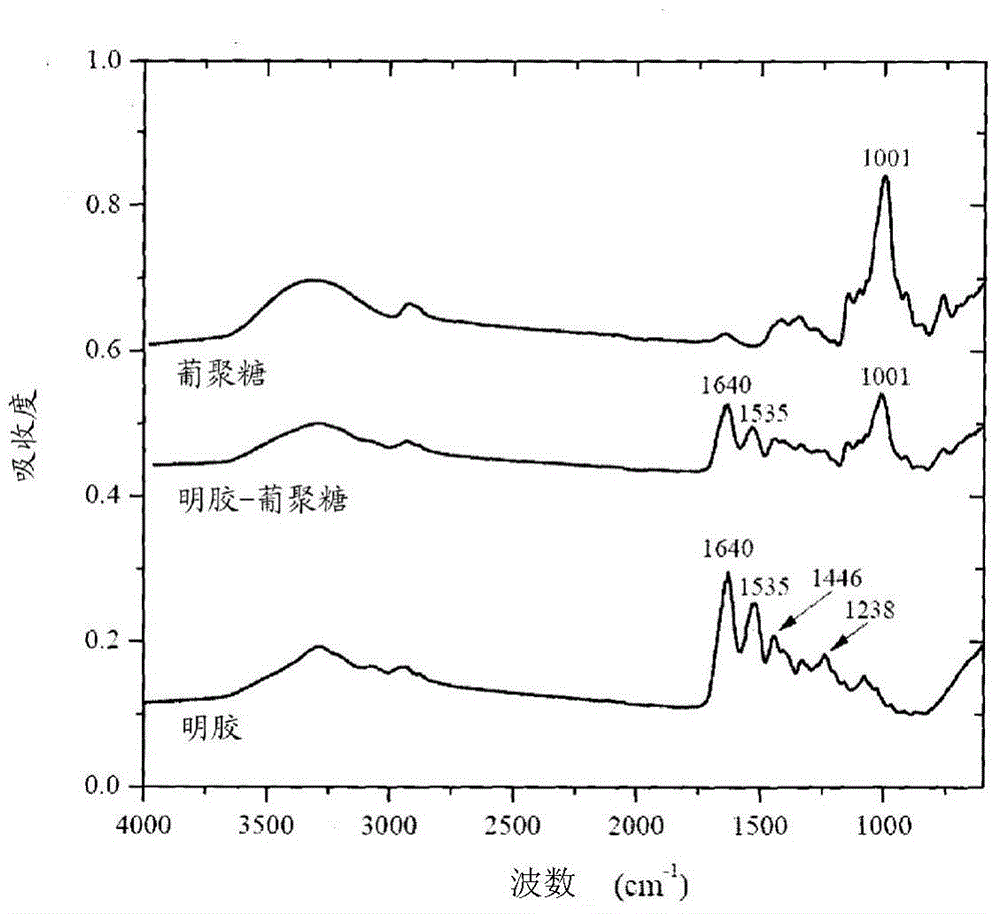

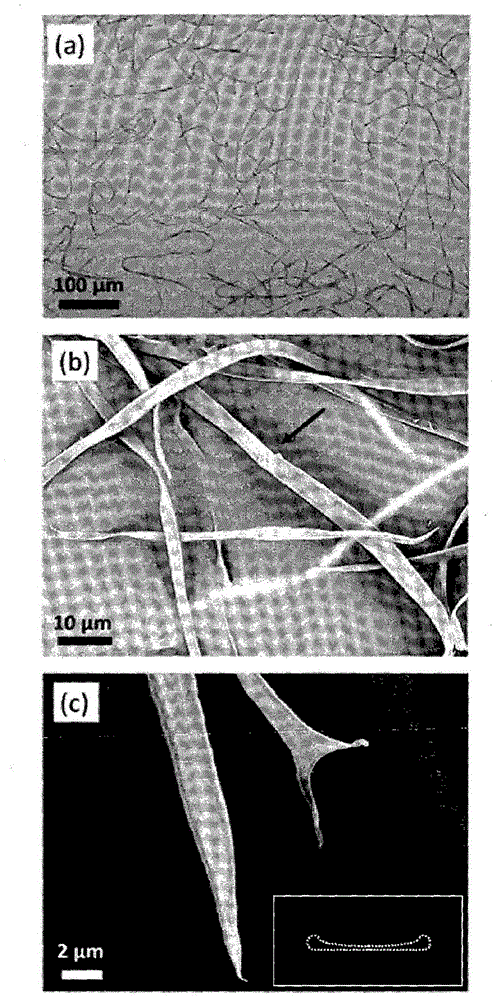

[0081] The exemplary embodiment shown below relates to a hybrid material comprising a hydrogel of dextran dialdehyde-cross-linked gelatin embedded with electrospun bovine serum albumin fibers. In this embodiment, the length of each fiber used ranges from about 100 μm to about 1000 μm. Incorporating fibers at a weight fraction of about 1% to about 6% increases the hydrogel elastic modulus by about 40% and reduces the gel time by about 20%.

[0082] Hybrid scaffolds, including hydrogels and short electrospun fibers, are also provided. Dextran dialdehyde-crosslinked gelatin was used as the hydrogel componen...

Embodiment 1

[0083] Example 1: Materials

[0084] Gelatin (type A, from pig skin), dextran (70 kDa, from Leuconostoc spp.), sodium periodate (ACS reagent, >99.8% pure), sodium tetraborate decahydrate (Borax) and 2,2,2-trifluoroethanol (TFE, Reagent Plus (R)) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Bovine serum albumin (BSA, Fraction V) was purchased from MP Biomedicals (Solon, OH, USA). 2-Mercaptoethanol (ME, molecular biology grade) was purchased from Merck (Darmstadt, Germany). All compounds were used without further modification.

Embodiment 2

[0085] Embodiment 2: Preparation of composite material hydrogel

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com