Cell-grade lithium metal casting device and method

A metal lithium, battery-level technology, which is applied to the battery-level metal lithium casting equipment and the field of casting, can solve the problems of long argon circulation cooling time, difficult to find leakage, large glove box space, etc. The effect of safe and reliable production operation and simple and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

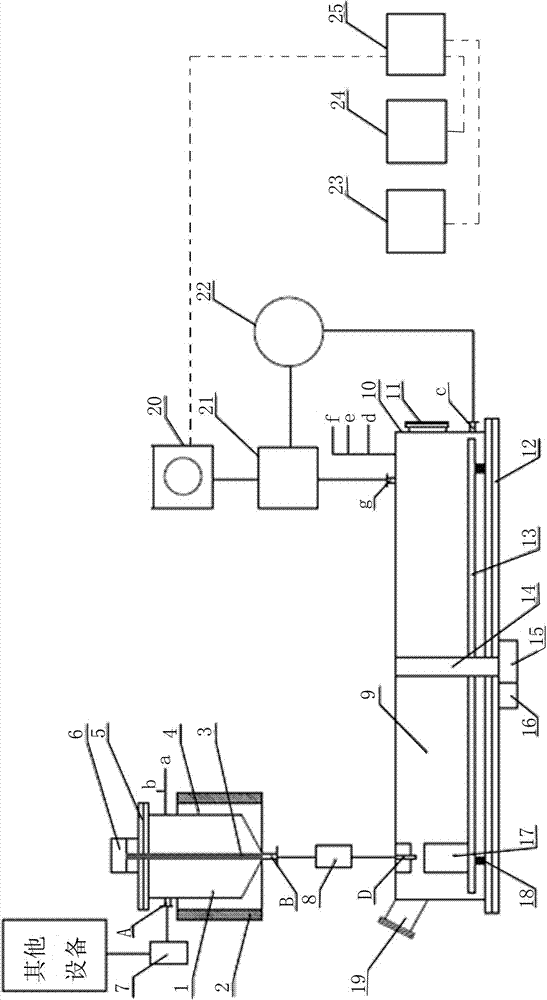

[0027] Refer to attached figure 1 , a battery-grade metal lithium casting equipment of the present invention includes a pure lithium tank 1, a disc casting machine 9, an argon gas circulation device, an argon gas device 24, a vacuum pump 23, a refrigeration unit 20 and a control cabinet 25;

[0028] One side of the upper part of the pure lithium tank 1 is provided with a feed pipe A, and the bottom of the pure lithium tank 1 is provided with a discharge pipe B; the other side of the upper part of the pure lithium tank 1 is provided with a pure lithium tank vacuum tube a and a pure lithium tank argon The air pipe b; the tank cover 5 and the tank body 4 on the upper part of the pure lithium tank 1 are fully sealed and connected by a flange, and the flange sealing ring is provided with upper and lower water-cooled jackets; the tank cover 5 is provided with a pneumatic valve cylinder 6, The pneumatic valve cylinder 6 and the long-stem valve 3 in the pure lithium tank 1 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com