Whole process tracking automatic adjustment system and control method of steel pipe pre-welding machine

An automatic adjustment and pre-welding machine technology, applied in the direction of manufacturing tools, welding equipment, tubular objects, etc., can solve the problems of high operator requirements, increased production and processing costs, and impact on quality, so as to save costs, human resources, replace and easy maintenance, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

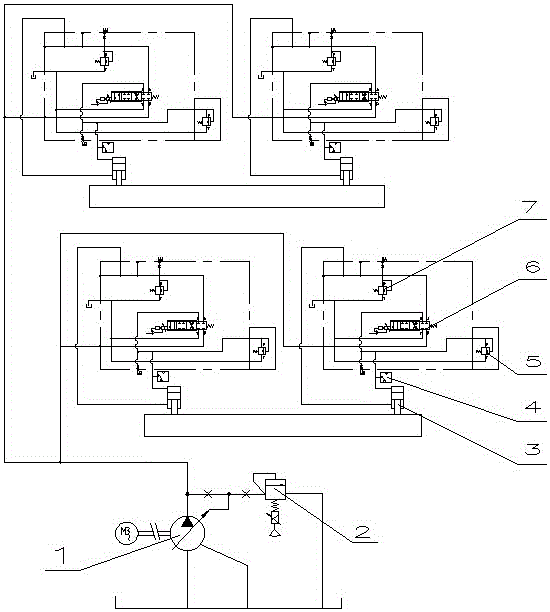

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0018] Such as figure 1As shown, a steel pipe pre-welding machine tracking automatic adjustment system includes an infrared inspection sensor connected to the head of the steel pipe pre-welding machine, and the infrared inspection sensor is connected to the image acquisition card of the control machine. The model of the infrared inspection sensor is VDM18-300 / 20 / 88 / 122 / 151. The infrared inspection sensor is connected with the operation panel. The operation panel mainly realizes man-machine exchange information, which is transmitted to the operation panel through PLC. The operation panel is connected with the steel pipe pre-welding machine welding torch tracking drive motor; The steel pipe pressing and maintaining system consists of power unit 1, proportional overflow valve 2, master cylinder 3 of steel pipe pre-welding machine, pressure sensor 4, upper chamber safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com