Carbon fiber cloth reinforced poplar laminated veneer lumber and making method thereof

A technology of poplar veneer and carbon fiber cloth, which is applied in the direction of wood layered products, wood veneer bonding, wood processing appliances, etc. problem, to achieve the effect of not easy delamination, wide application range and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

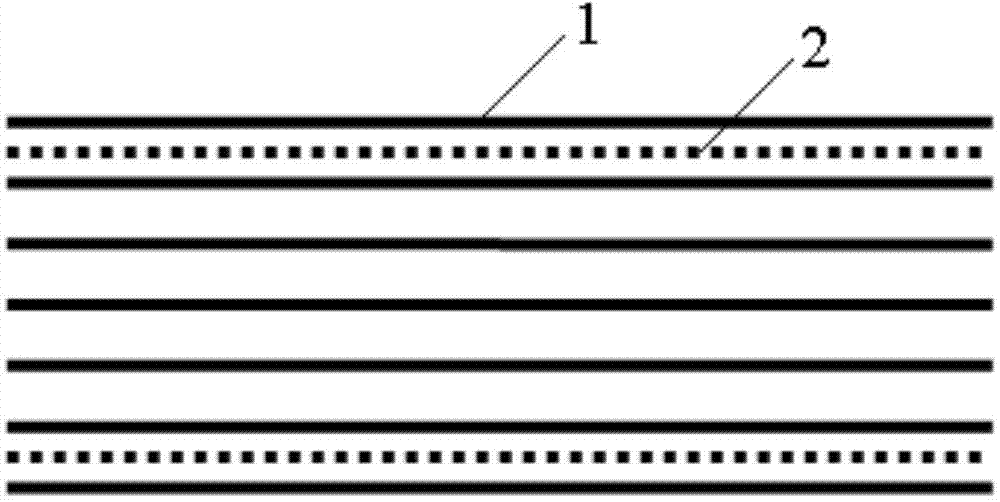

[0016] Embodiment 1: This embodiment is a carbon fiber cloth reinforced poplar veneer laminated lumber prepared from 7 poplar veneers and 2 carbon fiber cloths, and from top to bottom are poplar veneer, surface Treated carbon fiber cloth, poplar veneer, poplar veneer, poplar veneer, poplar veneer, poplar veneer, surface treated carbon fiber cloth and poplar veneer.

[0017] The advantage of this implementation mode:

[0018] 1. The carbon fiber cloth reinforced poplar laminated veneer lumber obtained in this embodiment has the advantages of high strength, wide application range, and not easy to delaminate;

[0019] 2. The static bending strength of the carbon fiber cloth reinforced poplar laminated veneer lumber obtained in this embodiment is 62MPa-65MPa, the elastic modulus is 8808MPa-8810MPa, and the shear strength is 8MPa-9MPa.

[0020] In this embodiment, a carbon fiber cloth-reinforced poplar laminated veneer lumber and a preparation method thereof can be obtained.

specific Embodiment approach 2

[0021] Specific implementation mode two: this implementation mode is a kind of preparation method of carbon fiber cloth reinforced poplar veneer laminated lumber, specifically completes according to the following steps:

[0022] 1. Add solvent to the silane coupling agent KH550 to obtain a silane coupling agent KH550 solution with a concentration of 1.0% to 2.5%; immerse the carbon fiber cloth in the silane coupling agent KH550 solution with a concentration of 1.0% to 2.5% for 5 minutes to After 15 minutes, take the carbon fiber cloth out of the silane coupling agent KH550 solution with a concentration of 1.0% to 2.5%, and then dry it at a temperature of 100°C to 130°C for 15min to 25min to obtain a carbon fiber cloth after surface treatment;

[0023] 2. Assemble the 7 poplar veneers according to the grain, and get the 7 poplar veneers after the grain formation. From top to bottom, they are 1# poplar veneer, 2# poplar veneer, and 3# poplar veneer. #poplar veneer, 4# poplar ven...

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, solvent is added to the silane coupling agent KH550 to obtain a silane coupling agent KH550 solution with a concentration of 1.5%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com