Preparation method of molybdenum disulfide nanosheet in stripping manner

A molybdenum disulfide, nanosheet technology, applied in the directions of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of high energy consumption, long preparation process cycle, and the peeling efficiency needs to be further improved, and achieve high efficiency and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

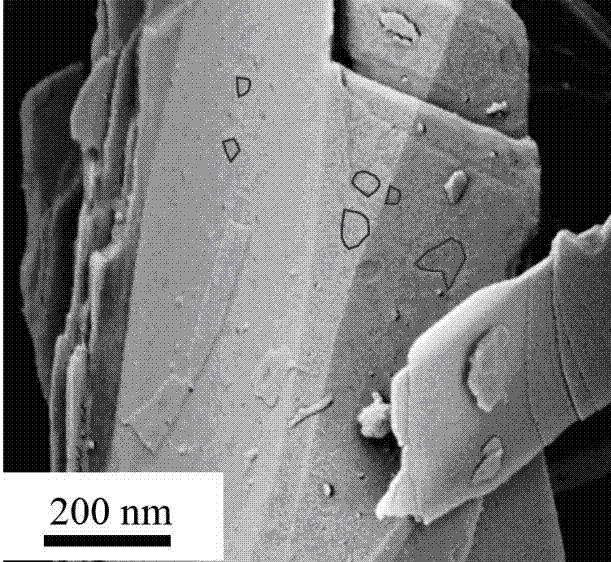

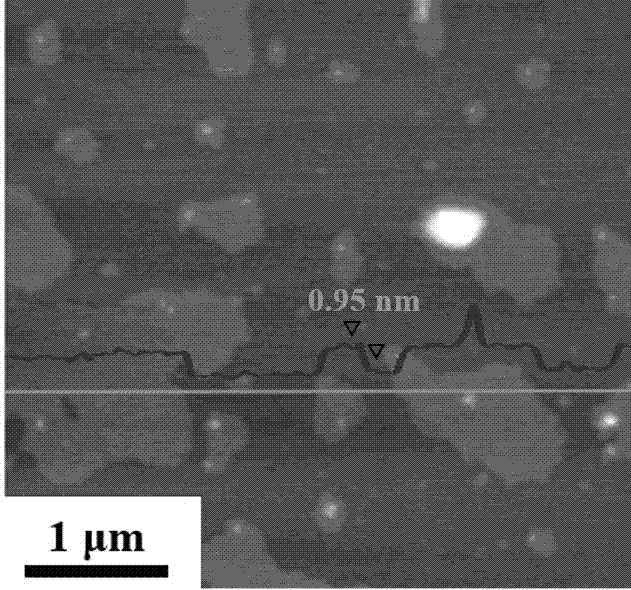

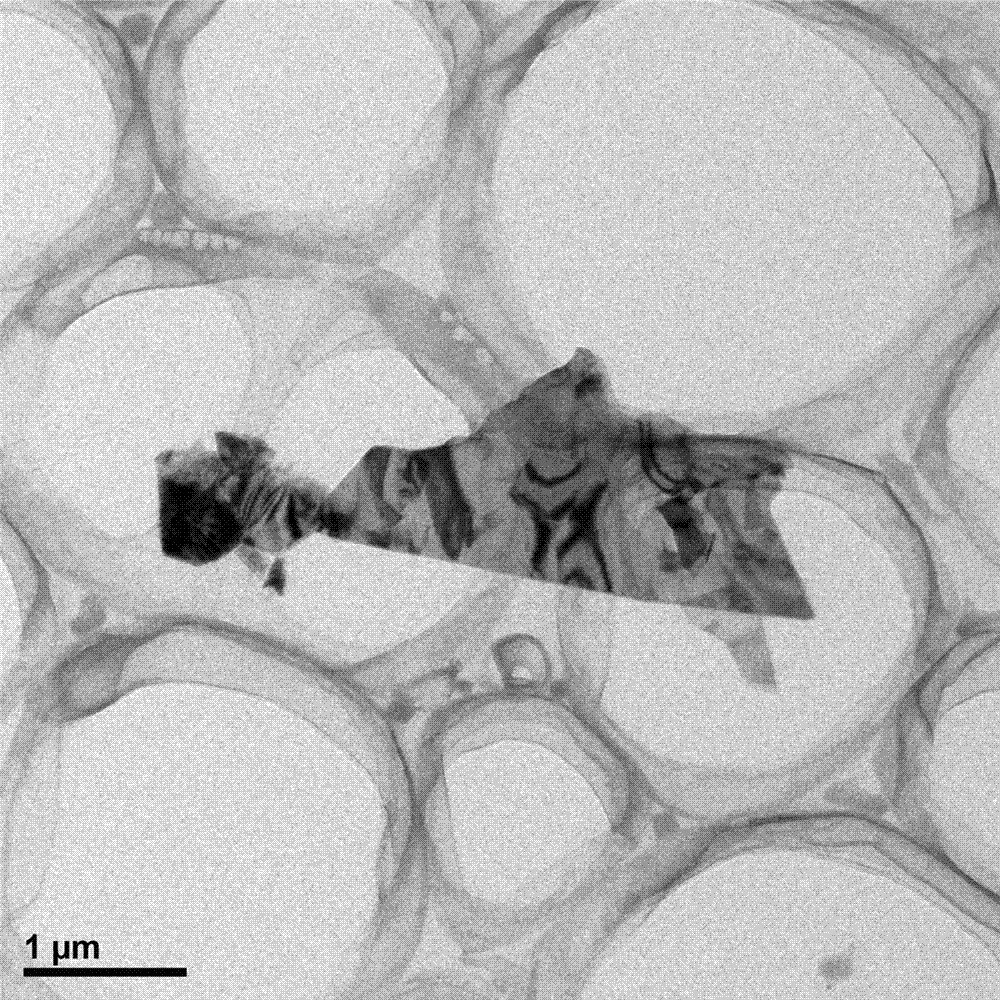

[0024] Disperse 20 mg of molybdenum disulfide powder in 20 ml of N-methyl-2-pyrrolidone mixed solvent containing hydrogen peroxide (NMP: 30% H 2 o 2 The mass ratio of the aqueous solution is 10:1), stirred at 35°C for 10 hours, and then cooled to room temperature. Centrifuge at 5000 rpm for 10 minutes to remove unstripped powder, collect the supernatant, filter and dry. The final exfoliated yield of molybdenum disulfide nanosheets is about 60 wt% (relative to the raw material powder). The scanning electron microscope image of the molybdenum disulfide raw powder before stripping is shown in figure 1 As shown, the atomic force microscopy and transmission electron microscopy images of the exfoliated nanosheets are shown in figure 2 and image 3 As shown in , the atomic force microscope photographs confirm that the height of the sheet is 0.95 nm, which is in line with the height of a typical single-layer molybdenum disulfide nanosheet.

Embodiment 2

[0026] Disperse 20 mg of molybdenum disulfide powder in 20 ml of N-methyl-2-pyrrolidone mixed solvent containing hydrogen peroxide (NMP: 30% H 2 o 2 The mass ratio of the aqueous solution is 100:1), stirred at 35°C for 10 hours, and then cooled to room temperature. Centrifuge at 5000 rpm for 10 minutes to remove unstripped powder, collect the supernatant, filter and dry. The final exfoliation yield of molybdenum disulfide nanosheets is greater than 60 wt% (relative to the raw material powder).

Embodiment 3

[0028] Disperse 100 mg of molybdenum disulfide powder in 20 ml of N-methyl-2-pyrrolidone mixed solvent containing hydrogen peroxide (NMP: 30% H 2 o 2 The mass ratio of the aqueous solution is 10:1), stirred at 35 °C for 10 hours, and then cooled to room temperature. Centrifuge at 5000 rpm for 10 minutes to remove unstripped powder, collect the supernatant, filter and dry. The final exfoliation yield of molybdenum disulfide nanosheets is greater than 30 wt% (relative to the raw material powder).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com