Aluminum oxide sol composite slurry

A technology of alumina sol and composite materials, which is applied in the direction of conductive coatings and coatings, can solve the problems of poor high temperature resistance, easy contamination, and insufficient conductivity to meet the conductivity, and achieve low cost and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below by example.

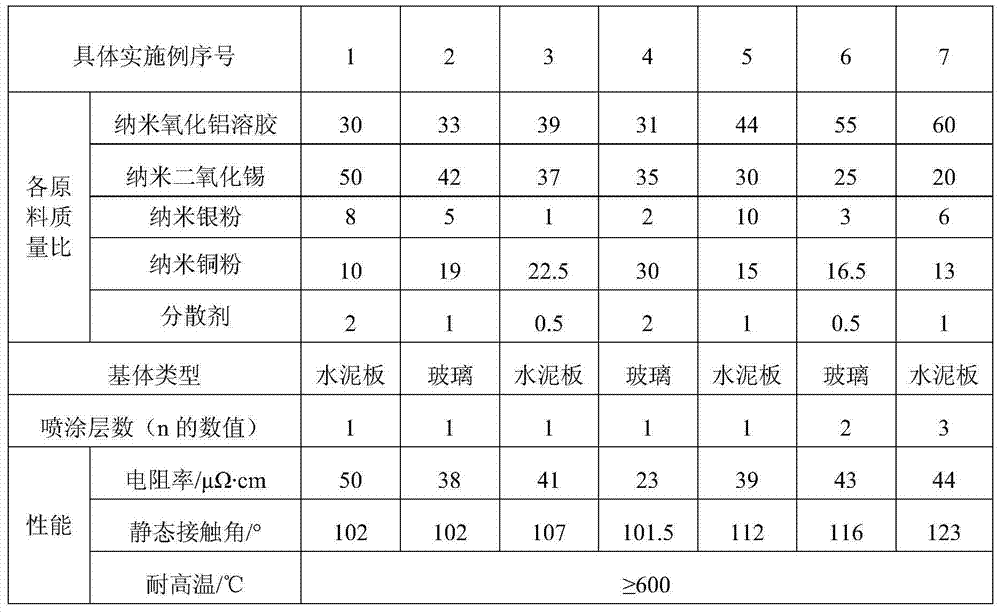

[0021] The alumina sol composite slurry in the present invention is formed by mixing the following raw materials in percentage by weight: 20-50% of nano-tin dioxide, 30-60% of nano-alumina sol, 5-10% of nano-silver powder, Copper powder 10-30% and dispersant 0.5-2%.

[0022] In this embodiment, the nano-tin dioxide is selected from the product with a purity of 99.99% produced by Shanghai Jingchun Biochemical Technology Co., Ltd., and the particle size is 50-70nm; the nano-alumina sol is selected from the mass concentration produced by Hefei Xiangzheng Chemical Technology Co., Ltd. It is the product of 20~25%, and particle size is 10~20nm; Nano-silver powder passes silver nitrate (analytical pure, molecular weight: 169.87, Sinopharm Chemical Reagent Co., Ltd.) and glucose (analytical pure, molecular weight: 198.17, Sinopharm Chemical Reagent Co., Ltd.) Company) prepared by reduction reaction at 25°C, the par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com