Multifunctional thermal-insulation putty and application method thereof

A thermal insulation putty, multi-functional technology, applied in the direction of filling slurry, etc., can solve the problems of inability to meet the needs of development and the application conditions of external wall putty, and achieve the effect of good anti-self-cracking effect, convenient construction and small thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

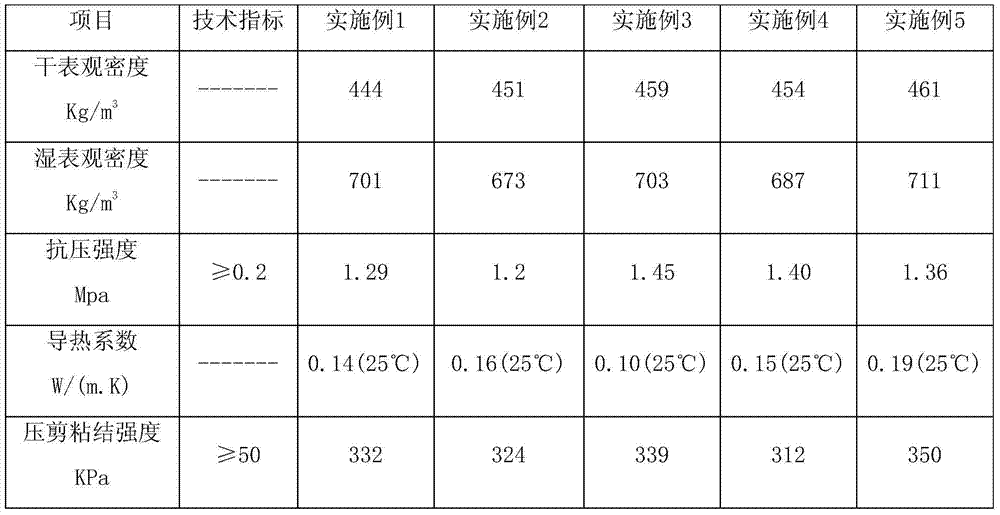

Examples

Embodiment 1

[0023] A multifunctional heat preservation putty, which comprises the following components and parts by weight content: 40 parts of cement, 15 parts of quartz powder, 8 parts of quartz sand, 20 parts of corrugated beads, 8 parts of gray calcium, heavy calcium 8 parts, 5 parts of Wacker rubber powder, 0.5 parts of Ruitai cellulose, 0.2 parts of ultra-short fiber, 0.5 parts of wood fiber, 0.2 parts of starch ether.

[0024] The particle size of quartz powder is 300 mesh; the particle size of quartz sand is 100 mesh; the particle size of vitrified beads is 1mm; the particle size of heavy calcium and gray calcium powder is 350 mesh; the length of ultra-short fiber is 2mm.

Embodiment 2

[0026] A multifunctional thermal insulation putty, which includes the following components and parts by weight content: 50 parts of cement, 12 parts of quartz powder, 4 parts of quartz sand, 27 parts of corrugated beads, 5 parts of gray calcium, and heavy calcium 6 parts, 2 parts WACKER rubber powder, 1 part Ruitai cellulose, 0.05 parts ultra-short fiber, 0.8 parts wood fiber, 0.4 parts starch ether.

[0027] The particle size of quartz powder is 450 mesh; the particle size of quartz sand is 80 mesh; the particle size of vitrified beads is 1mm; the particle size of heavy calcium and gray calcium powder is 400 mesh; the length of ultra-short fiber is 2.5mm.

Embodiment 3

[0029] A multifunctional heat preservation putty, which comprises the following components and parts by weight content: 45 parts of cement, 10 parts of quartz powder, 5 parts of quartz sand, 25 parts of corrugated beads, 5 parts of gray calcium, heavy calcium 5 parts, 3.13 parts of Wacker powder, 0.78 parts of Ruitai cellulose, 0.31 parts of ultra-short fiber, 0.47 parts of wood fiber, and 0.31 parts of starch ether.

[0030] The particle size of quartz powder is 500 mesh; the particle size of quartz sand is 80 mesh; the particle size of vitrified beads is 0.5 mm; the particle size of heavy calcium and gray calcium powder is 300 mesh; the length of ultra-short fiber is 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com