Assembled type special-shaped hollow column frame-shear wall housing construction system and assembling method

A frame system and residential building technology, applied in the direction of building, building components, building structure, etc., can solve the problem that rectangular and circular columns cannot fully consider the applicability of residential buildings, affect the safety performance of buildings, and the quality of welding seams is not easy to control. and other problems, to achieve the effect of increasing the usable area of the building, excellent fire performance, and increasing the usable area of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

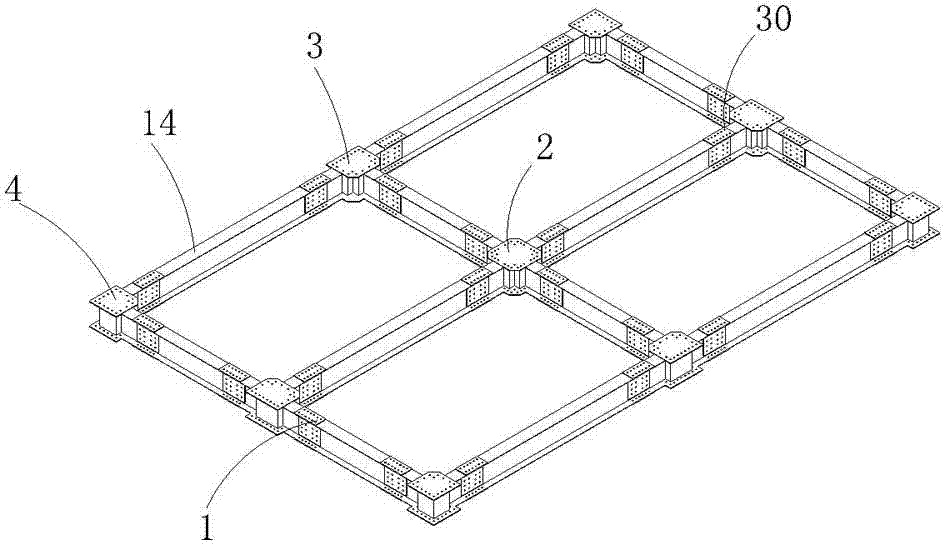

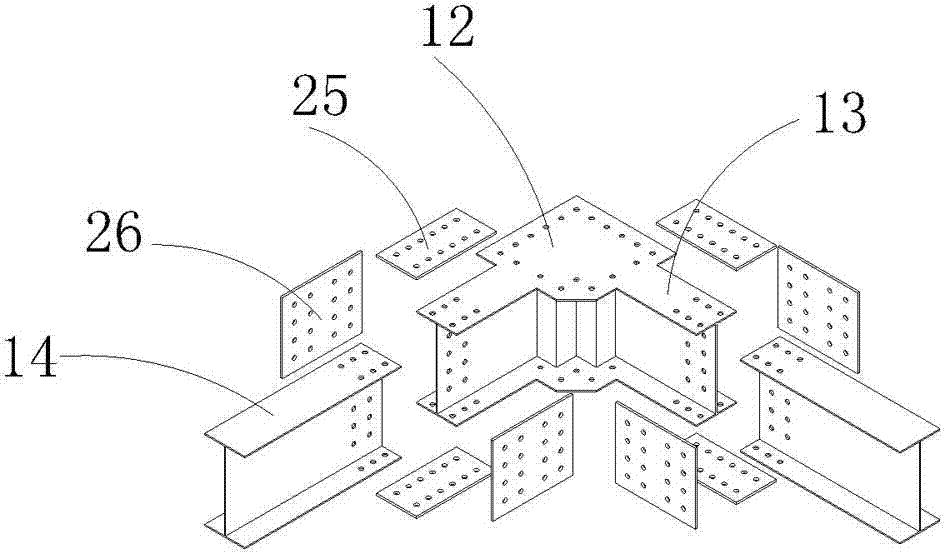

[0065] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, an assembled special-shaped hollow column frame-shear wall residential building system includes at least a two-story frame system 1, and the two-story frame system 1 is continuously distributed up and down, and the frame system 1 includes at least one central column mechanism 2 , at least 4 side column mechanisms 3 and at least 4 corner column mechanisms 4, the four ends of the center column mechanism 2 are fixedly connected with the side column mechanisms 3 respectively, the two ends of the side column mechanisms 3 are respectively fixedly connected with the corner column mechanisms 4, and the center The upper part of the column mechanism 2 is provided with a central steel column mechanism 5, the upper part of the side column mechanism 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com