Coordination type deep-sea oil transportation pipeline

An oil pipeline and deep-sea technology, applied in the field of coordinated deep-sea oil pipeline, can solve the problems that the bending resistance of the inner and outer pipes cannot be fully utilized, the pressure of the inner and outer pipes cannot be continuously transmitted, and the insulation layer does not have structural properties, etc., so that it is not easy to deform , High mechanical strength, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

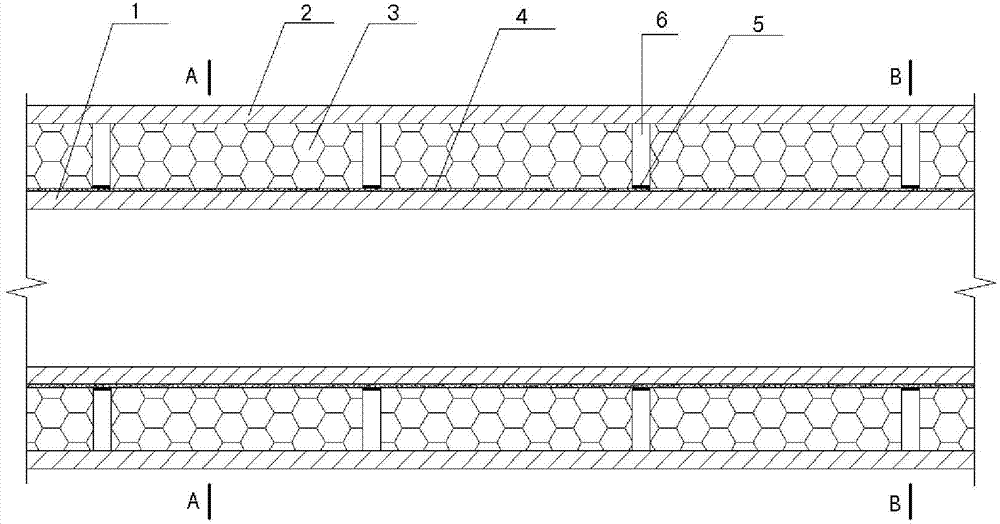

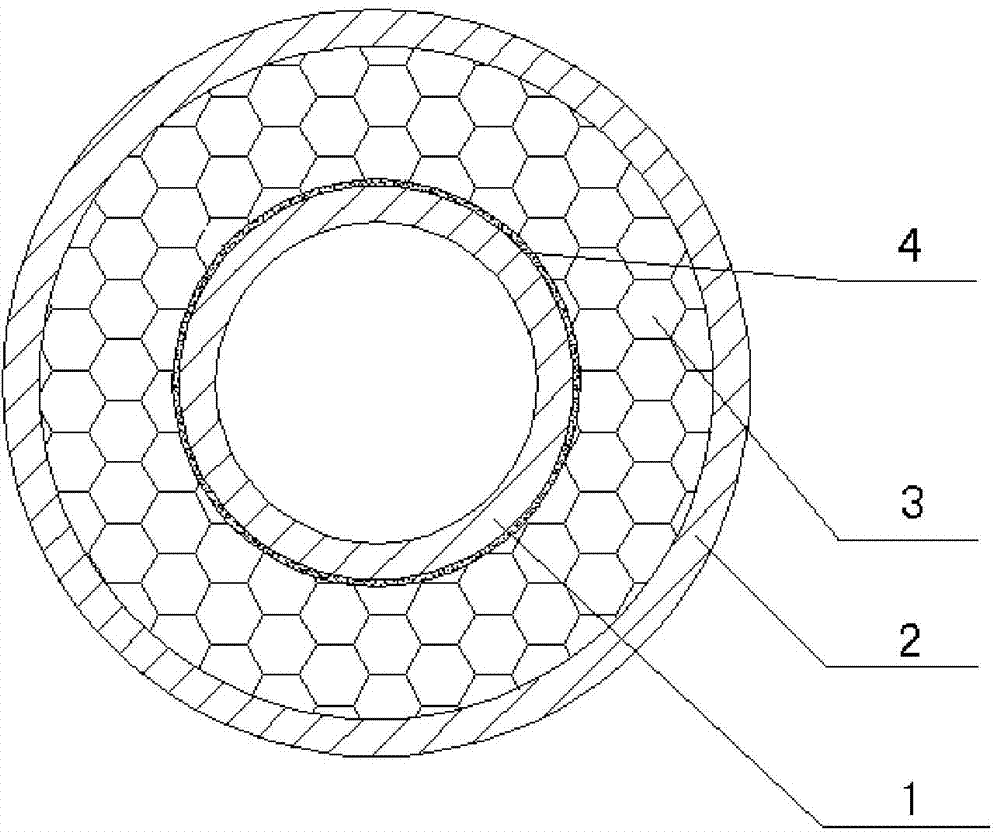

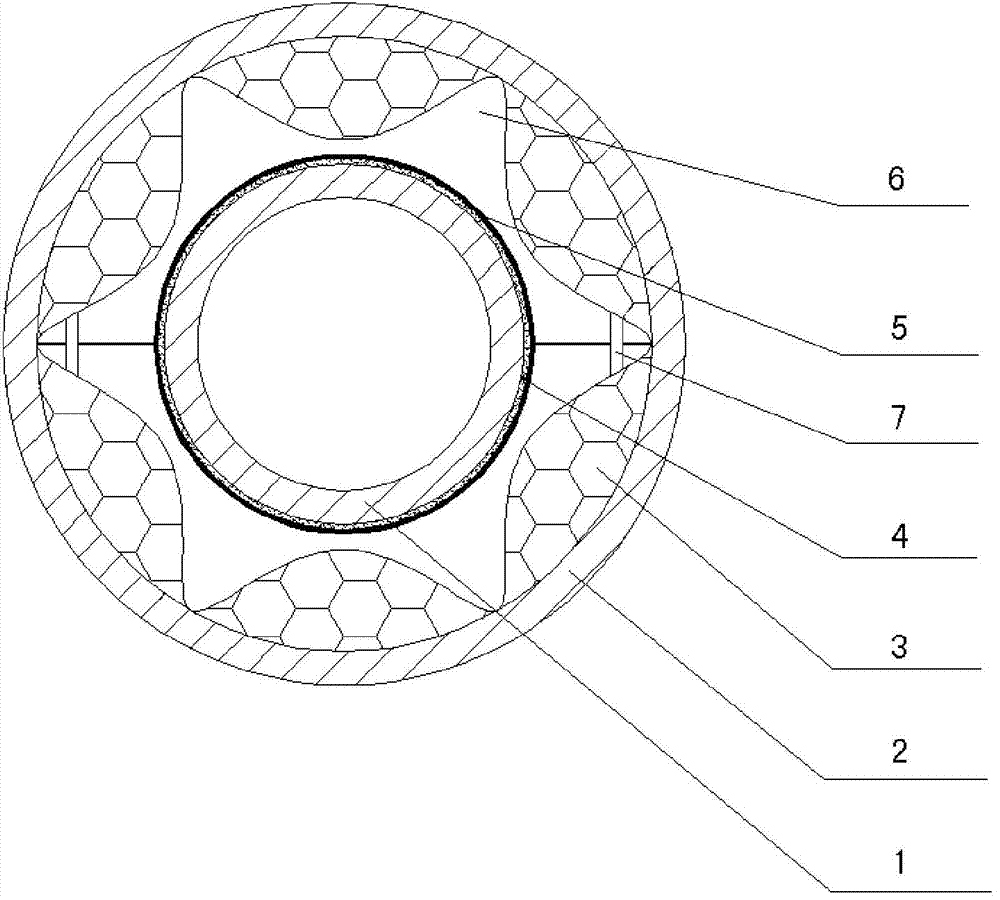

[0031] The present invention will be further described below in conjunction with the drawings:

[0032] Such as Figure 1 to Figure 4 As shown, a coordinated deep-sea oil pipeline includes an inner pipe 1 and an outer pipe 2. The inner pipe 1 and the outer pipe 2 are both made of steel casing, and the inner pipe 1 and the outer pipe 2 are filled with insulation material 3 The structural insulation layer is formed. The thickness of the insulation layer is usually 30-150mm. The insulation material 3 is made of polyurethane foam or foamed cement. The outer wall of the inner pipe 1 is coated with an anticorrosive layer 4, which is composed of fused epoxy powder , The thickness is 0.06-0.15mm, the anti-slip mat 5 is wound at equal intervals on the anti-corrosion layer 4, and the anti-slip mat 5 is provided with a centering ring 6. The centering ring 6 is made of polyamide nylon, has a semicircular structure with continuous grooves, and is provided with connecting holes on both sides,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com