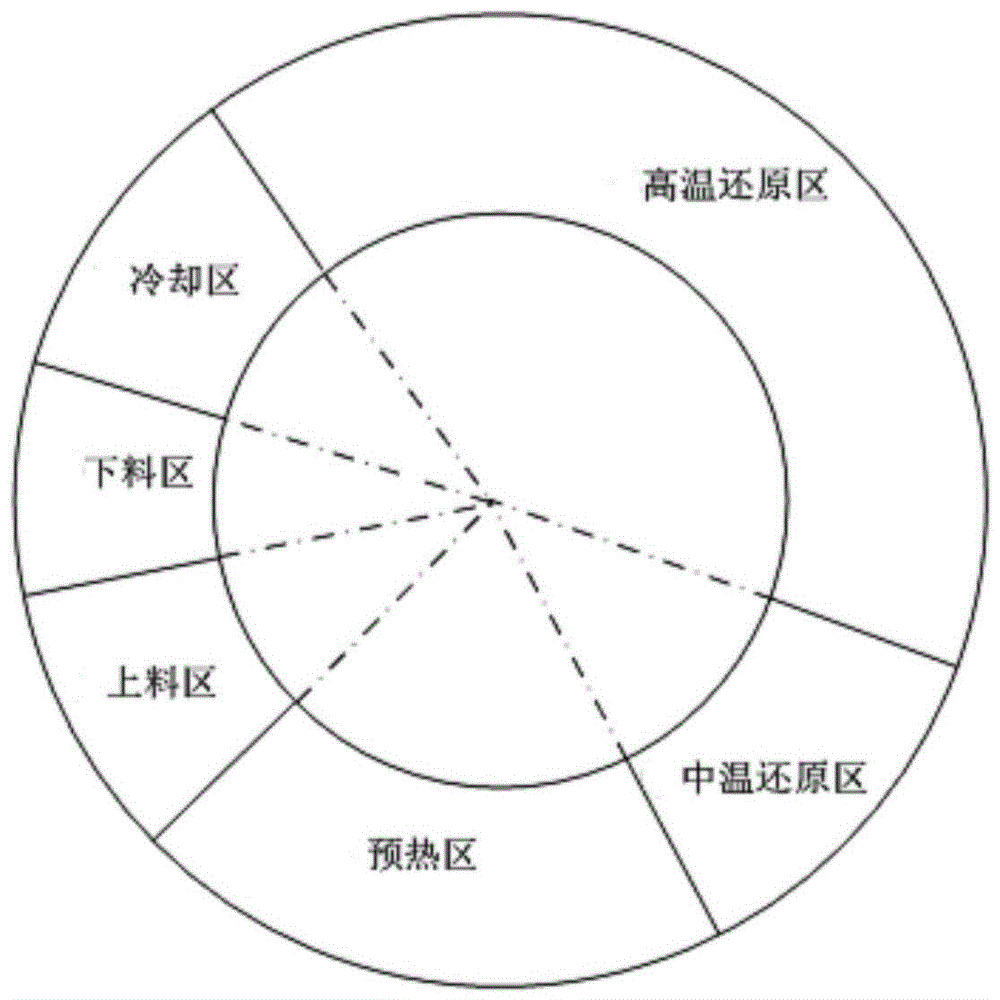

A Rotary Hearth Furnace Bottom Structure Realizing Thick Material Layer Reduction

A rotary hearth furnace bottom and rotary hearth furnace technology, applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve the problem of increasing the temperature of carbon-containing pellets, increasing the input of rotary hearth furnace equipment, and limiting the height of material layers, etc. problem, to achieve the effect of increasing the thickness of the thick material layer, shortening the reduction time, and preventing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

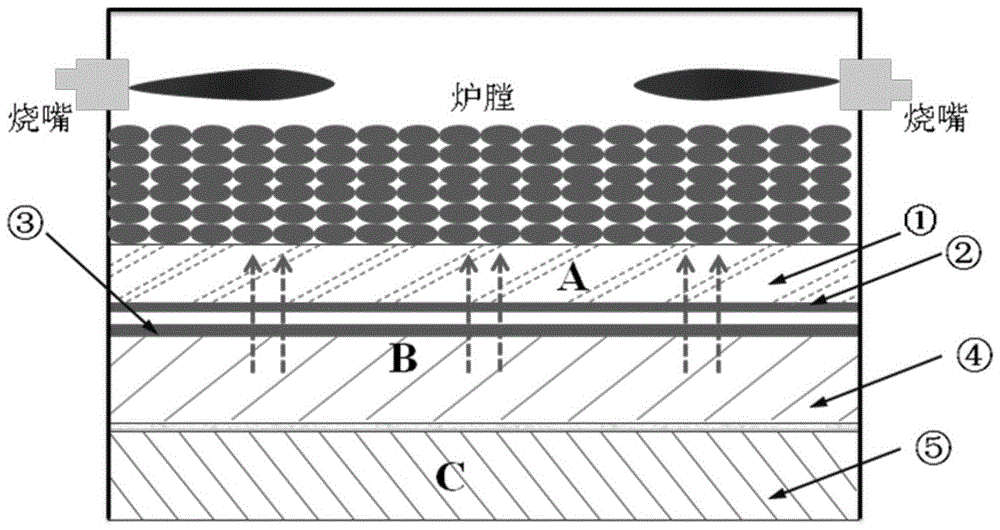

Embodiment 1

[0039] The rotary hearth furnace with the furnace bottom structure designed by the invention is used to quickly reduce the copper slag with a thick material layer. The paving thickness is 150-200mm; the resistance wires made of 0Cr27Al7Mo2 are embedded in the heating layer corresponding to the preheating zone, the medium temperature reduction zone and the high temperature reduction zone, and the number of resistance wires in the heating layer corresponding to the medium temperature reduction zone is The number of resistance wires in the heating layer corresponding to the preheating zone is 1.5 times, and the number of resistance wires in the heating layer corresponding to the high temperature reduction zone is 2 times the number of resistance wires in the heating layer corresponding to the preheating zone; The resistance wire heats the material upward from the bottom of the furnace, and the radiant tube on the furnace wall heats the material downward from the horizontal directi...

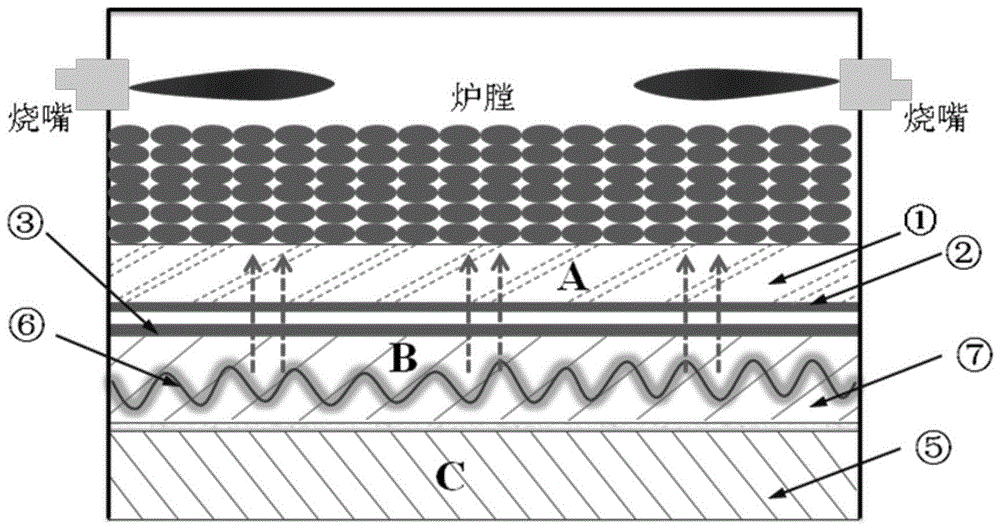

Embodiment 2

[0041] The rotary hearth furnace with the furnace bottom structure designed by the invention is used to quickly reduce the vanadium-titanium sea placer with a thick material layer. The paving thickness is 100-150 mm; resistance wires made of 0Cr27Al7Mo2 are embedded in the heating layer corresponding to the preheating zone, medium temperature reduction zone and high temperature reduction zone, and the number of resistance wires in the heating layer corresponding to the medium temperature reduction zone is The number of resistance wires in the heating layer corresponding to the preheating zone is 1.5 times, and the number of resistance wires in the heating layer corresponding to the high temperature reduction zone is 2 times the number of resistance wires in the heating layer corresponding to the preheating zone; The resistance wire heats the material upwards from the bottom of the furnace, and the radiant tube on the furnace wall heats the material downwards from the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com