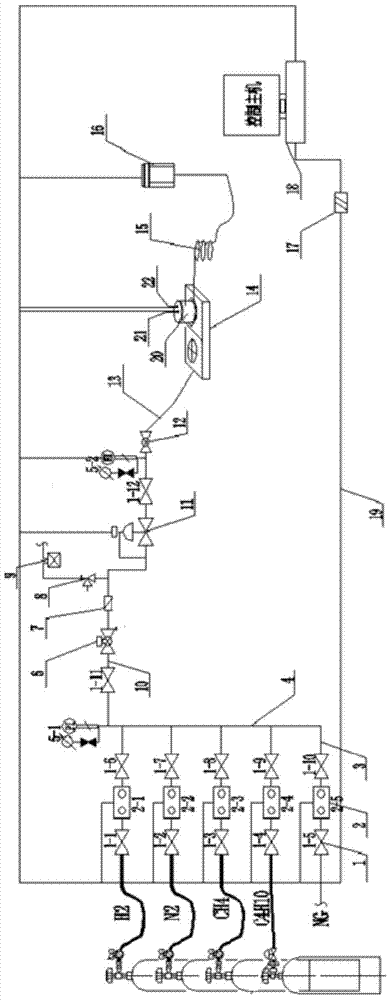

Mobile integrated gas cooker comprehensive performance experiment tester and test method

A technology for comprehensive performance testing and gas cooker, which is applied to a mobile integrated gas cooker comprehensive performance testing experiment test device and its testing field, and achieves the effects of powerful functions, flexible structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A comprehensive performance testing method for a "mobile integrated" gas cooker is carried out according to the following steps:

[0039] (1) Carry out an air tightness test.

[0040] Place or install the gas cooker on the test bench, and use a special gas leak detector or the air or nitrogen pipeline that comes with the system to check the gas tightness of the gas system and combustion system of the gas cooker.

[0041] (2) Adjustment of combustion conditions.

[0042] According to the reference gas source category, rated air supply pressure and rated heat load parameters marked on the nameplate of the gas cooker, set the reference gas, burn and ignite; adjust the best combustion condition of the cooker by adjusting the air damper at the bottom of the cooker, and maintain the The state remains unchanged, and all test processes are completed.

[0043] (3) Carry out thermal load test.

[0044] Using the rated pressure and reference gas marked on the cooker, within 15-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com