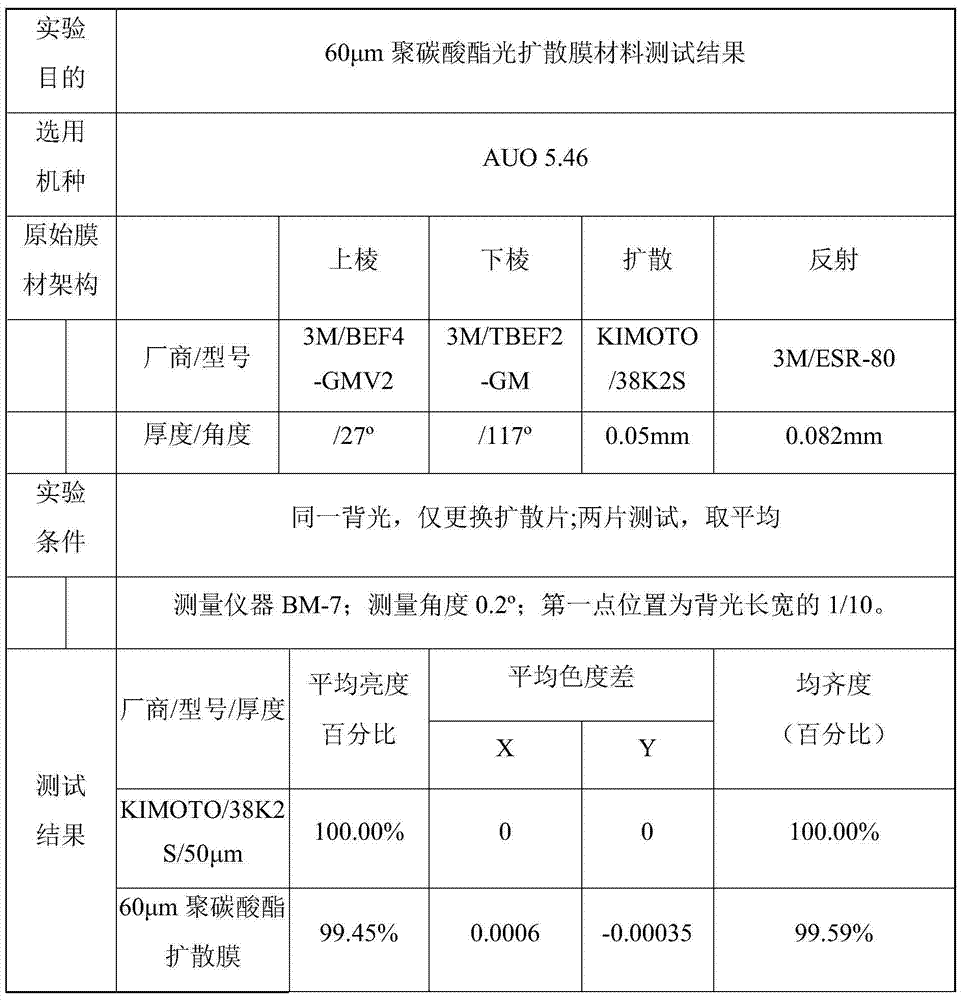

Polycarbonate light diffusion film for backlight displaying of mobile phone and preparation method of polycarbonate light diffusion film

A polycarbonate, light diffusing film technology, applied in optics, optical components, educational appliances, etc., can solve the problems of pollution, PET diffusion film easily deformed, diffusion coating falling off environment, etc., to prevent pollution and facilitate subsequent production and processing , the effect of high quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A polycarbonate light-diffusing film for mobile phone backlight display of the present invention and a preparation method thereof will be described in detail below in conjunction with specific embodiments.

[0036] The raw material and mass percent of polycarbonate light diffusion film of the present invention are as follows:

[0037] Polycarbonate 93%~98%

[0038] Silicone resin 1%~7%

[0039] PMMA powder 1% to 7%.

[0040] Raw material: Polycarbonate Teijin Chemicals

[0041] Silicone resin Shin-Etsu Silicone Particle size 2μm~4μm

[0042] PMMA micropowder Soken Chemical Particle size 3μm~5μm

[0043] Special equipment: high-mix and low-mix compounding units; special machine for polycarbonate light diffusion masterbatch; optical film production line; roller group with lens structure.

[0044] The plastic extrusion process is one-time molding, without the use of chemical liquid additives such as organic solvents, and has no organic gas hazards to the environment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com