Environmental-protection type fabric dry cleaning agent

A dry cleaning agent, an environmentally friendly technology, applied in the directions of detergent compounding agent, detergent composition, detergent composition fragrance, etc., which can solve the problems of inconvenient removal with water and not necessarily removing dirt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

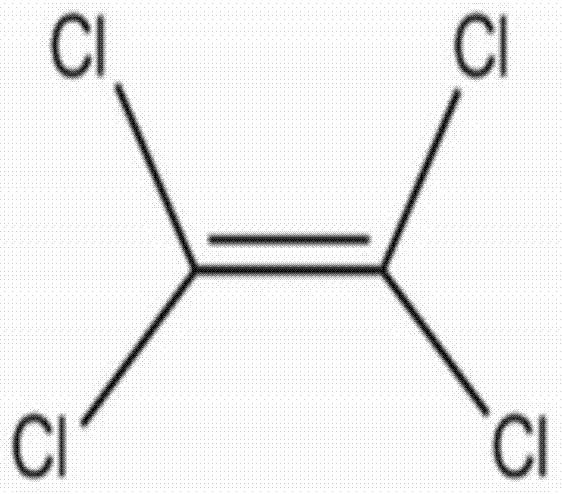

Image

Examples

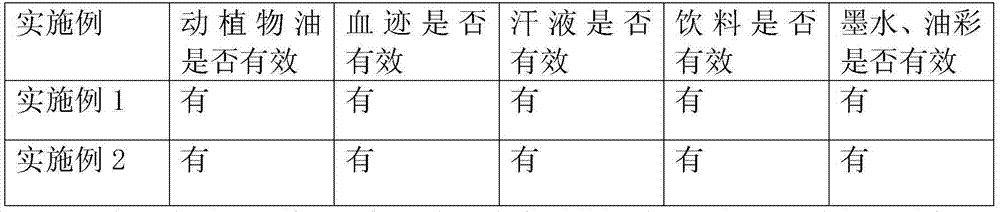

Embodiment 1

[0017] 24 parts of sodium sulfate of fatty alcohol polyoxyethylene ether, 2 parts of wormwood, 15 parts of rosemary extract, 35 parts of perchlorethylene, 5 parts of centipede, 5 parts of orange oil, 10 parts of ethanol, and 4 parts of citric acid.

[0018] Will be prepared according to the above ratio, the steps are as follows:

[0019] (1) Add Baibu and Artemisia argyi into a ball mill and grind for 3-4 hours, and pass through a 200-mesh sieve to reach the qualified standard;

[0020] (2) Add fatty alcohol polyoxyethylene ether sodium sulfate, ethanol, and citric acid into the reaction kettle, raise the temperature to 60°C±2°C, keep the stirring speed at 2500 rpm, and keep stirring for 1-2 hours;

[0021] (3) Add the qualified raw materials of babu and mugwort into the reaction kettle, and naturally cool down to 30°C ± 2°C while stirring;

[0022] (4) At 30°C±2°C, add orange oil, tetrachloroethylene, and rosemary extract to the reaction kettle, and stir for 1 hour to obtain...

Embodiment 2

[0024] 20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2 parts of wormwood, 11 parts of rosemary extract, 37 parts of perchlorethylene, 6 parts of basil, 7 parts of orange oil, 12 parts of ethanol, and 5 parts of citric acid.

[0025] Will be prepared according to the above ratio, the steps are as follows:

[0026] (1) Add Baibu and Artemisia argyi into a ball mill and grind for 3-4 hours, and pass through a 200-mesh sieve to reach the qualified standard;

[0027] (2) Add fatty alcohol polyoxyethylene ether sodium sulfate, ethanol, and citric acid into the reaction kettle, raise the temperature to 60°C±2°C, keep the stirring speed at 2500 rpm, and keep stirring for 1-2 hours;

[0028] (3) Add the qualified raw materials of babu and mugwort into the reaction kettle, and naturally cool down to 30°C ± 2°C while stirring;

[0029] (4) At 30°C±2°C, add orange oil, tetrachloroethylene, and rosemary extract to the reaction kettle, and stir for 1 hour to obtain the pr...

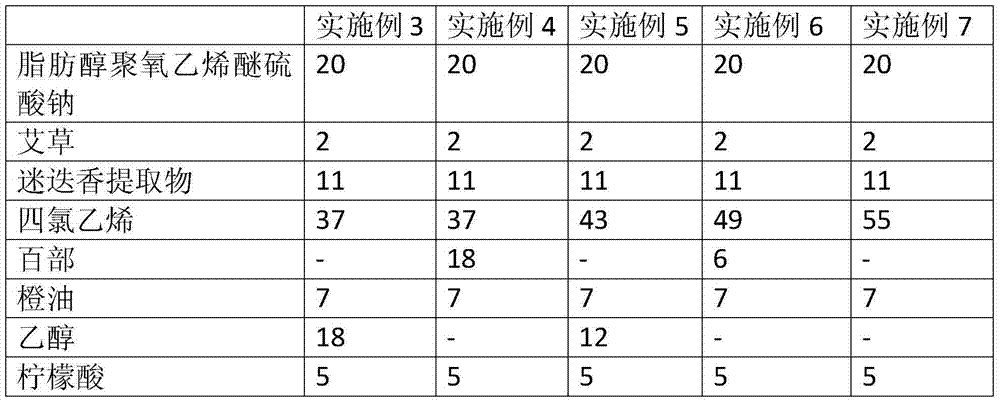

Embodiment 3

[0043] Contrast in embodiment 3,4,5,6 can find out, embodiment 3 single addition of ethanol is poorer than the effect of single addition of 100 parts, but embodiment 5,6 can find out that single addition of ethanol or 100 parts, increase in quantity is also Effective ones, Table 5.

[0044] table 5

[0045] Example

Escherichia coli sterilization rate%

Staphylococcus aureus sterilization rate%

Example 3

82

72

Example 4

90

81

Example 5

85

76

Example 6

79

68

[0046] As can be seen from Examples 5, 6, and 7, increasing ethanol or basil has a bactericidal effect, as shown in Table 6.

[0047] Table 6

[0048] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com