Passive temperature measuring sensor of substation primary equipment

A technology for primary equipment and temperature measurement, applied in thermometers, measuring heat, measuring devices, etc., can solve the problems of difficult to adapt to the strong magnetic field of the substation, the working environment of strong interference, the high power consumption of the chip, and the inconvenience of use, so as to improve the inspection Efficiency, strong applicability and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

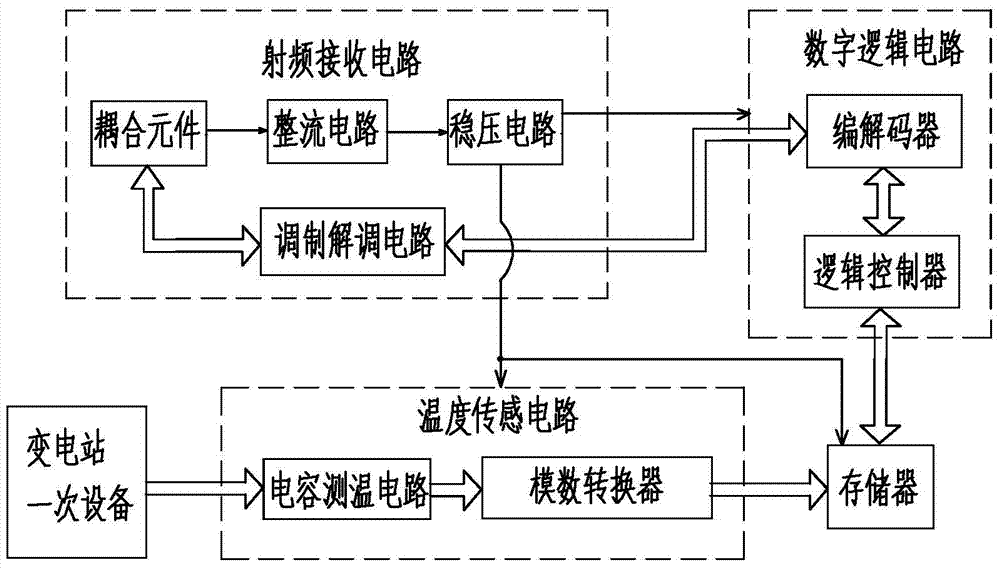

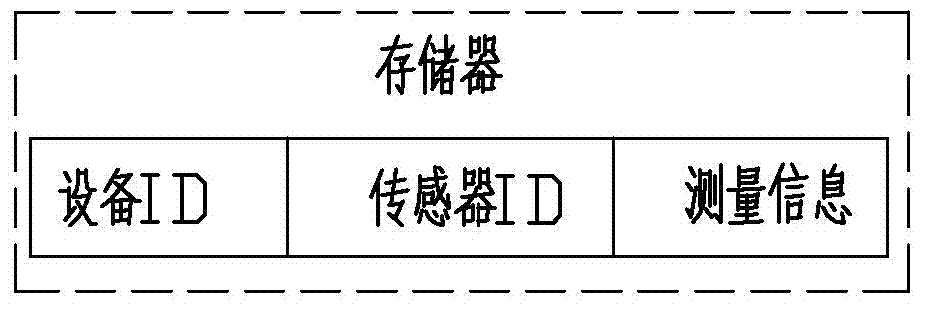

[0015] See figure 1 , the substation primary equipment passive temperature measurement sensor of this embodiment is mainly composed of a radio frequency receiving circuit, a temperature sensing circuit, a digital logic circuit and a memory.

[0016] The radio frequency receiving circuit is mainly composed of a coupling element, a rectifying circuit, a voltage stabilizing circuit and a modulation and demodulation circuit. On the one hand, the coupling element is used to couple with the electromagnetic field to obtain magnetic energy, and on the other hand, it is used to receive and send radio frequency electromagnetic wave signals of corresponding frequencies. The rectifier circuit is used to convert the alternating magnetic energy transferred by the coupling element into a DC voltage. The voltage stabilizing circuit is used to stabilize the voltage output by the rectifying circuit and then output the working power of the sensor. The modulation and demodulation circuit is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com