Laser collimation and beam expansion system for deep ultraviolet lithography

A technology of laser collimation beam expansion and deep ultraviolet light, applied in the field of laser collimation beam expansion, can solve the problem that the final beam shape, size and divergence angle cannot meet the requirements of use, and achieve compact structure, small size change and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

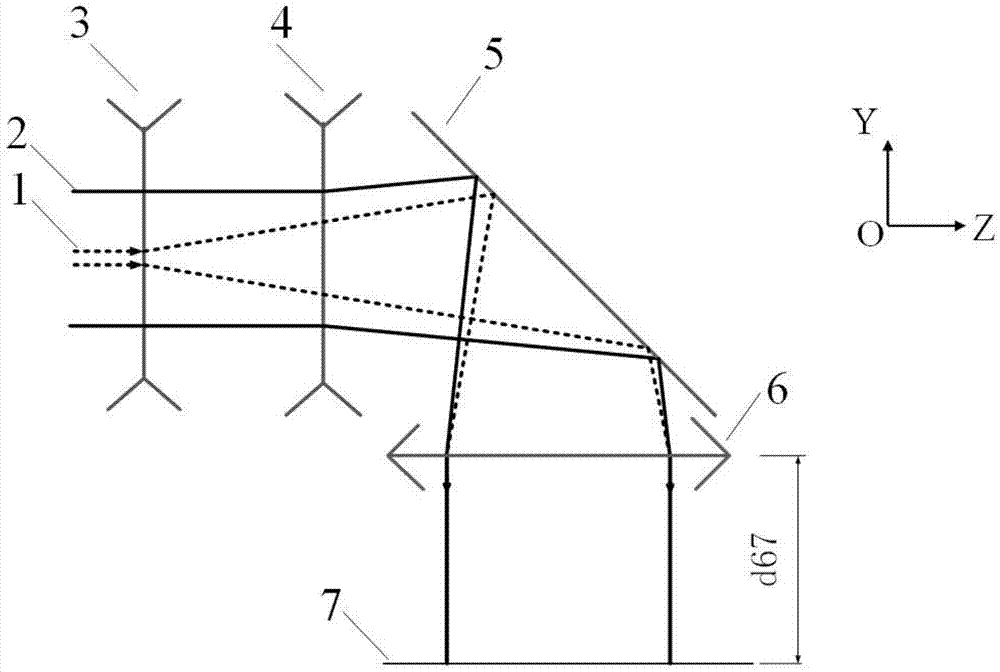

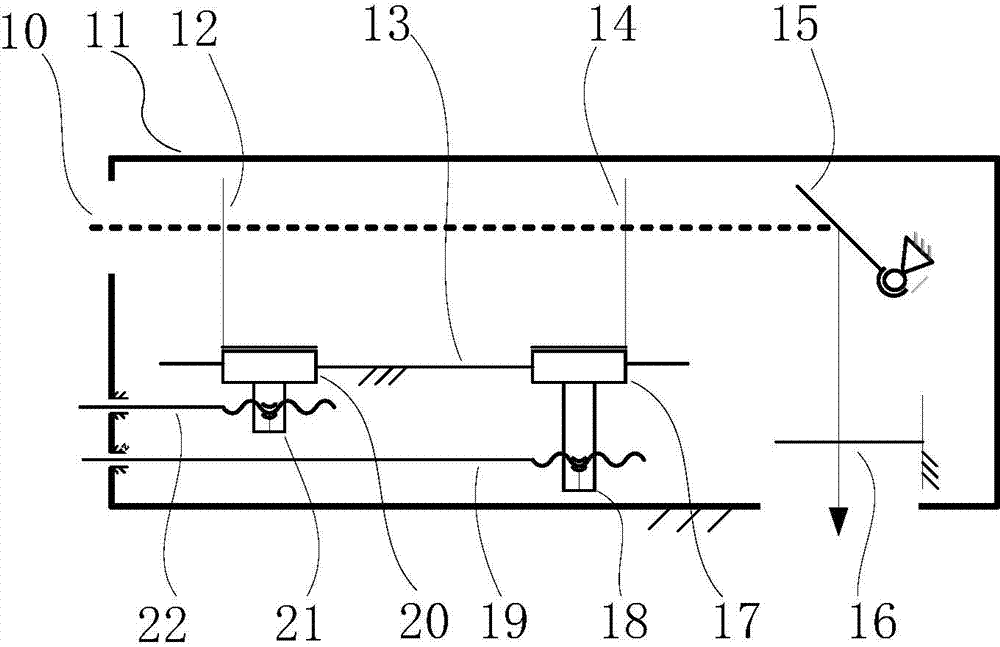

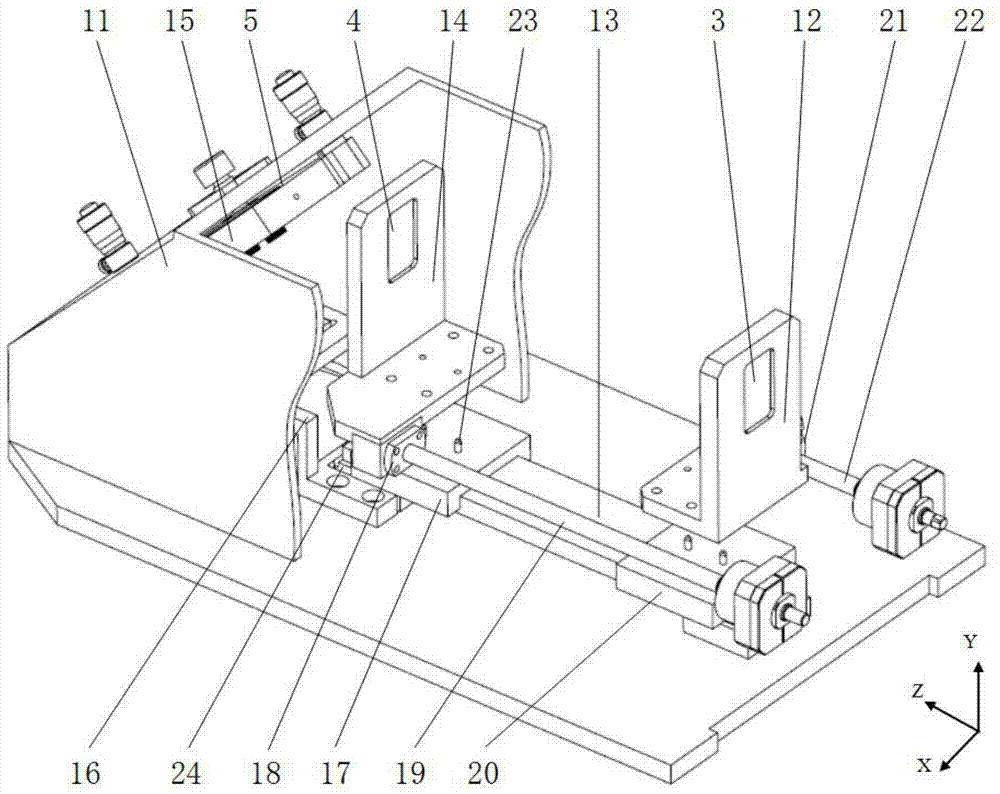

[0040] figure 1 It is a schematic diagram of the principle of the laser collimation and beam expansion system. The laser collimation and beam expansion system is composed of the first cylindrical mirror 3, the second cylindrical mirror 4, the plane mirror 5 and the spherical mirror 6. The spherical mirror 6 is connected with the first cylindrical mirror 3 respectively. and the second cylindrical mirror 4 to form two collimating beam expanders. Since the laser beam may have a divergence angle, in the present invention, the propagation direction of the center beam of the beam is taken as the propagation direction of the entire beam. Taking the propagation direction of the central beam of the laser output beam along the positive direction of the Z axis as an example, a Cartesian coordinate system is established, the focal power of the first cylindrical mirror 3 is in the X direction and is negative, and the cross-section of the laser beam emitted by the laser is at Divergence in...

Embodiment 2

[0068] Such as Figure 4 As shown, on the basis of Embodiment 1, a second reflector 8 and a second spherical mirror 9 are added, and 7 is the light source input port in the photolithography machine. The second reflector 8 reflects the light path at 90 degrees, and its position and quantity are arranged according to needs, so that the light beam transmission path can be flexibly designed. Adding the second spherical mirror 9 can realize the beam index required in Embodiment 1 when the laser transmission distance exceeds 15m or even longer, which greatly increases the application occasions of the laser beam expander system.

[0069] Only change the beam transmission distance requirement in Embodiment 1, keep the output beam parameters of the laser light source, and require the output light source parameters to be the same as in Embodiment 1, and still use the first cylindrical mirror 3, the second cylindrical mirror 4 and the spherical mirror in Embodiment 1 6 parameters.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com