Method of forming semiconductor device

A semiconductor and device technology, which is applied in the field of semiconductor device formation, can solve the problems of the semiconductor substrate being easily damaged, affecting the electrical performance of the semiconductor device, etc., and achieve the effects of improving electrical performance, optimizing electrical performance, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As mentioned in the background, the electrical performance of semiconductor devices formed in the prior art is poor.

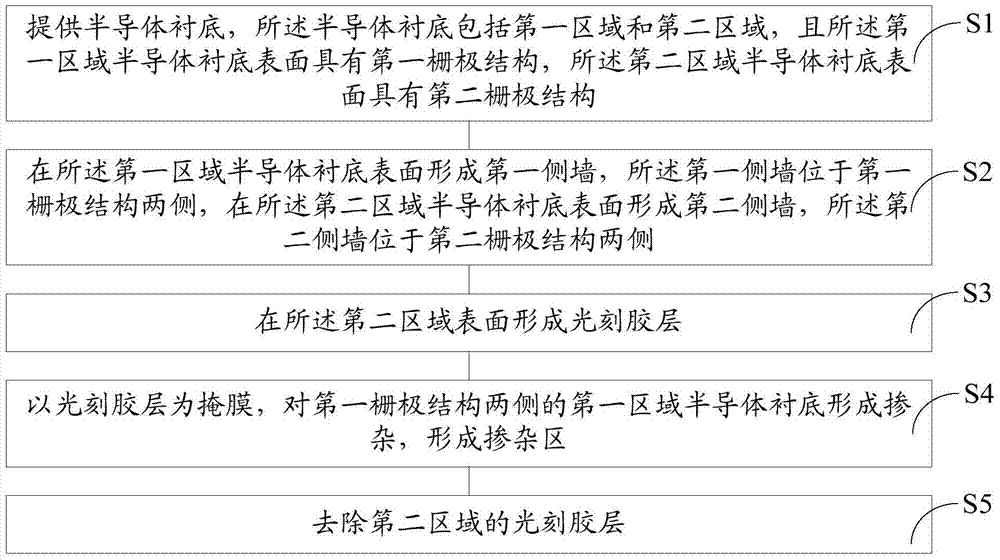

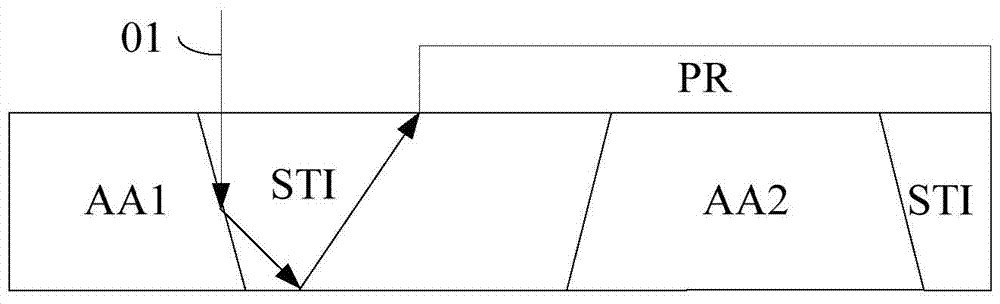

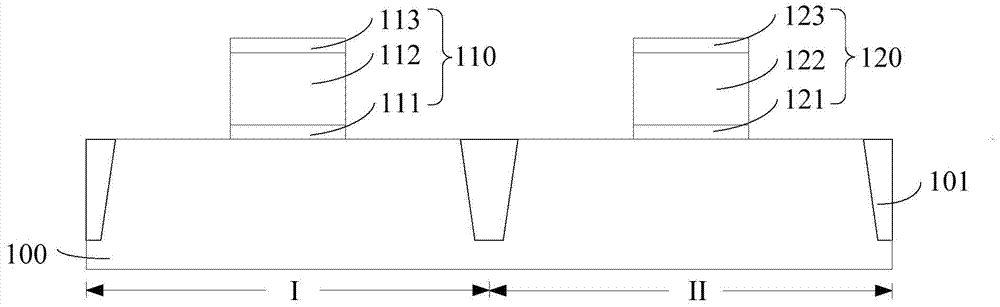

[0030] To this end, research is conducted on the formation method of semiconductor devices. The formation method of semiconductor devices includes the following steps, please refer to figure 1 : Step S1, providing a semiconductor substrate, the semiconductor substrate includes a first region and a second region, and the surface of the semiconductor substrate in the first region has a first gate structure, and the surface of the semiconductor substrate in the second region has The second gate structure; step S2, forming first sidewalls on the surface of the semiconductor substrate in the first region, the first sidewalls are located on both sides of the first gate structure, and on the surface of the semiconductor substrate in the second region Forming second sidewalls, the second sidewalls are located on both sides of the second gate structure; step S3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com