Acotiamide hydrochloride medicinal preparation and preparation method thereof

A technology of acotiamide hydrochloride and acotiamide hydrochloride trihydrate, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

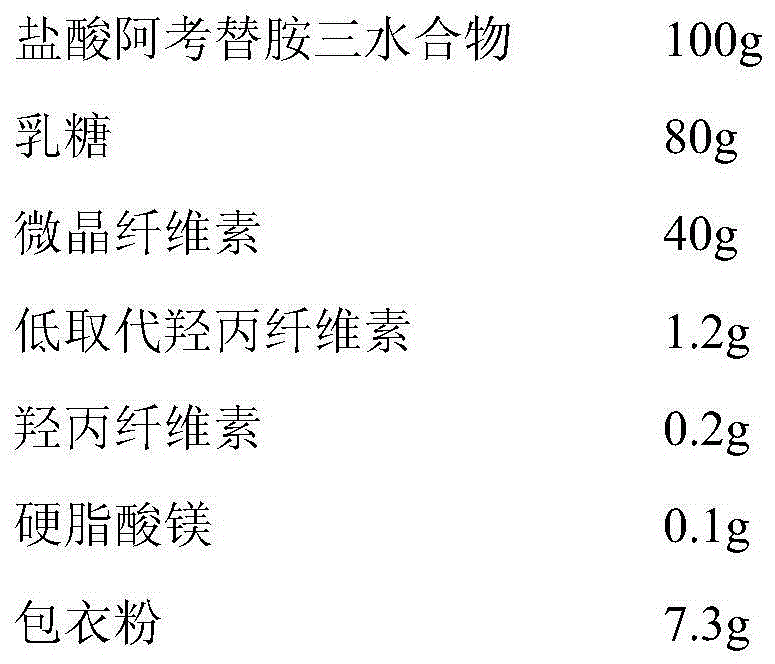

[0028] Embodiment 1 (1000 pieces amount)

[0029]

[0030]Put the raw materials into a common pulverizer to pulverize and pass through a 80-mesh sieve. Weigh the prescribed amount of acotiamide hydrochloride trihydrate and lactose in a wet granulator and pre-mix until the uniformity RSD value of the mixture is less than 3.0%, add microcrystalline cellulose and low-substituted hydroxypropyl cellulose and mix evenly, add viscose The mixture is made of soft material, granulated with a 20-mesh sieve, dried in a constant temperature oven (fluidized bed drying), granulated with a 20-mesh sieve, added with the prescribed amount of magnesium stearate, blended, tabletted, coated, and packaged.

Embodiment 2

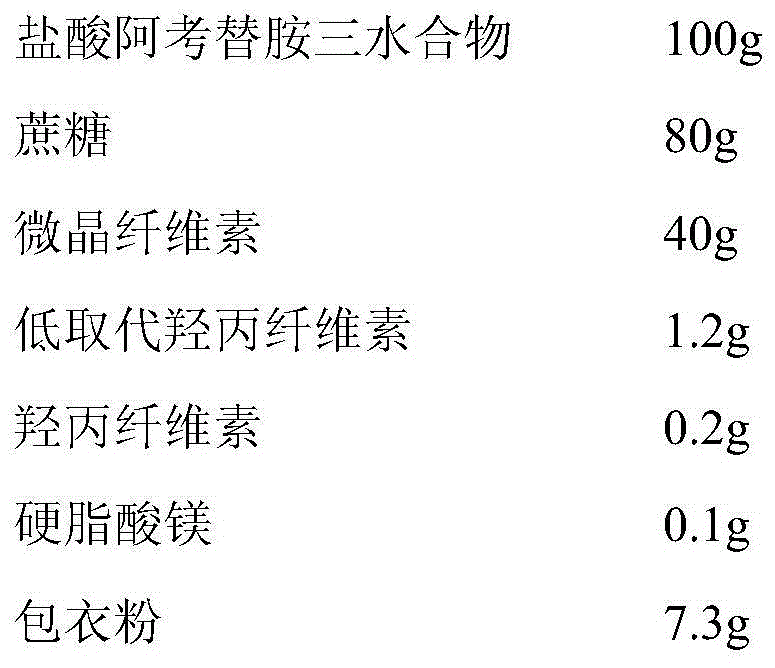

[0031] Embodiment 2 (quantity of 1000 pieces)

[0032]

[0033] Put the raw materials into a common pulverizer to pulverize and pass through a 80-mesh sieve. Weigh the prescribed amount of acotiamide hydrochloride trihydrate and sucrose in a wet granulator and pre-mix until the uniformity RSD value of the mixture is less than 3.0%, add microcrystalline cellulose and low-substituted hydroxypropyl cellulose and mix evenly, add viscose The mixture is made of soft material, granulated with a 20-mesh sieve, dried in a constant temperature oven (fluidized bed drying), granulated with a 20-mesh sieve, added with the prescribed amount of magnesium stearate, blended, tabletted, coated, and packaged.

Embodiment 3

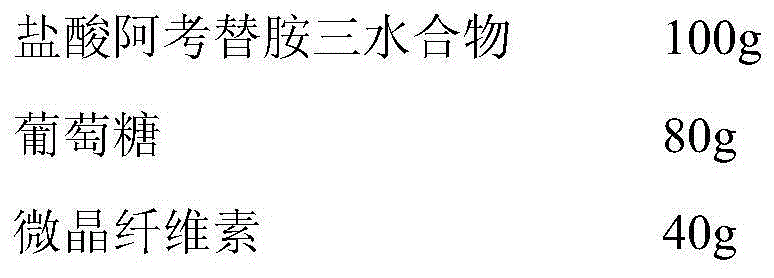

[0034] Embodiment 3 (quantity of 1000 pieces)

[0035]

[0036]

[0037] Put the raw materials into a common pulverizer to pulverize and pass through a 80-mesh sieve. Weigh the prescribed amount of acotiamide hydrochloride trihydrate and glucose in a wet granulator and pre-mix until the uniformity RSD value of the mixture is less than 3.0%, add microcrystalline cellulose and low-substituted hydroxypropyl cellulose and mix evenly, add viscose The mixture is made of soft material, granulated with a 20-mesh sieve, dried in a constant temperature oven (fluidized bed drying), granulated with a 20-mesh sieve, added with the prescribed amount of magnesium stearate, blended, tabletted, coated, and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com