Polyhedral Pd-Pt alloy nano catalyst and preparation method and application of nano catalyst

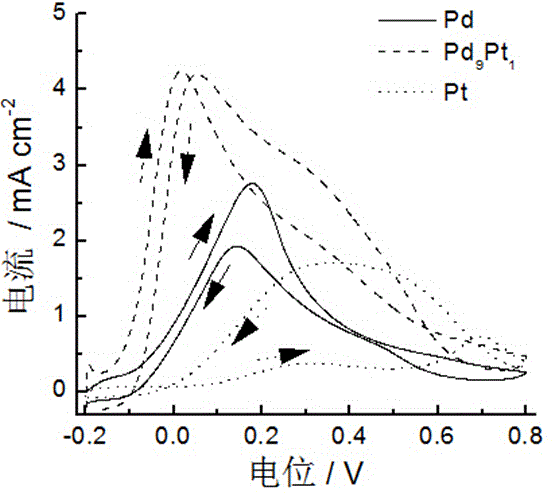

A nano-alloy and catalyst technology, applied in the field of electrochemical energy, can solve the problems of high cost and limited platinum resources, and achieve the effects of good dispersion, lower manufacturing costs, and reduced usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

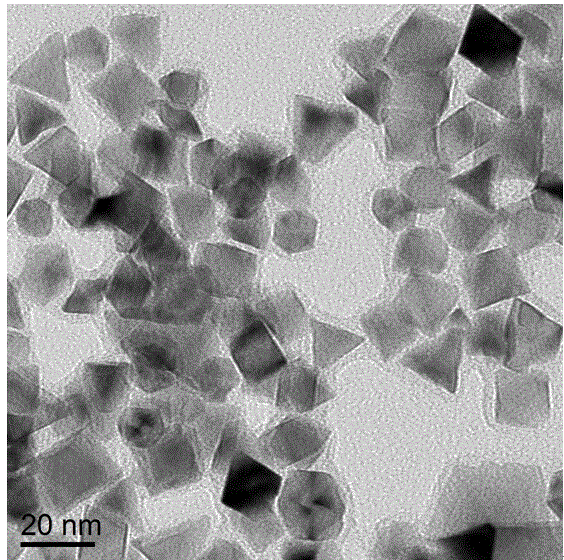

[0029] The preparation of embodiment 1, Pt1Pd9 alloy

[0030] Get 5.2mg of chloroplatinic acid solid and 15.9mg of palladium chloride solid (the ratio of platinum to palladium is 1:9) and dissolve in the mixed solution of methanol and water (the volume ratio of methanol to water is 1:1); 117.3mg octaaminosilsesquioxane (the mol ratio of metal precursor and octaaminosilsesquioxane is 1: 1), use 1mol / L hydrochloric acid solution to adjust the pH value of above-mentioned mixed solution to 5 after ultrasonic oscillation, keep Stirring is the full contact and complexation of the stabilizer with Pd ions and Pt ions to obtain the active metal precursor mixed solution; the prepared raw material solution is transferred to a hydrothermal reactor, the reaction temperature is 90-170 °C, and the reaction time is 10 h; The reduced nanomaterials are separated from the liquid, washed with water and ethanol several times, and heated and dried in a vacuum oven at 50-90°C to prepare polyhedral P...

Embodiment 2

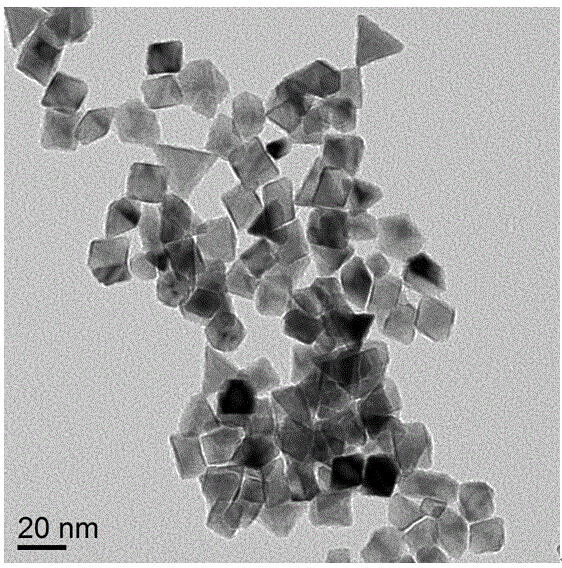

[0033] The preparation of embodiment 2, Pt3Pd7 alloy

[0034]Get 15.5mg of chloroplatinic acid solid and 12.5mg of palladium chloride solid (the ratio of platinum to palladium is 3:7) and dissolve in the mixed solution of methanol and water (the volume ratio of methanol to water is 3:1); 234.6mg octaaminosilsesquioxane (the mol ratio of metal precursor and octaaminosilsesquioxane is 1: 5), use 1mol / L hydrochloric acid solution to adjust the pH value of above-mentioned mixed solution to 3 after ultrasonic oscillation, keep Stir to fully contact and complex the stabilizer with Pd ions and Pt ions to obtain a mixed solution of active metal precursor; transfer the prepared raw material solution to a hydrothermal reactor, the reaction temperature is 90-170 ° C, and the reaction time is 6 h; The reduced nanomaterials are separated from the liquid, washed with water and ethanol several times, and heated and dried in a vacuum oven at 50-90°C to prepare polyhedral Pt3Pd7 alloy nanocata...

Embodiment 3

[0036] The preparation of embodiment 3, Pt5Pd5 alloy

[0037] Get 25.9mg of chloroplatinic acid solid and 8.9mg of palladium chloride solid (the ratio of platinum to palladium is 5:5) and dissolve in the mixed solution of methanol and water (the volume ratio of methanol to water is 6:1); 234.6mg octaaminosilsesquioxane (the mol ratio of metal precursor and octaaminosilsesquioxane is 1: 2), use 1mol / L hydrochloric acid solution to adjust the pH value of above-mentioned mixed solution to 7 after ultrasonic oscillation, keep Stir to make the stabilizer fully contact and complex with Pd ions and Pt ions to obtain the active metal precursor mixed liquid; transfer the prepared raw material liquid to a hydrothermal reaction kettle, the reaction temperature is 90-170 ° C, and the reaction time is 5 h; The reduced nanomaterials are separated from the liquid, washed with water and ethanol several times, and heated and dried in a vacuum oven at 50-90°C to prepare polyhedral Pt5Pd5 alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com