A hydrogenation catalyst for preparing hydrogenated petroleum resin and its preparation method

A technology for hydrogenation of petroleum resins and hydrogenation catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of resin hydrogenation catalysts that have not been industrialized Issues such as reports and research started late, to achieve the effects of increasing lifespan, improving dispersion effect, and slowing down poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0024] By weight percentage, the main catalyst Pd, the content is 0.5wt%; the co-catalyst Ag, the content is 0.3wt%; 2 o 3 Is the balance; Catalyst carrier γ-Al 2 o 3 , its specific surface area is 110m 2 / g, pore volume 0.45ml / g, bulk density 0.65g / cm 3 .

[0025] Preparation method: prepare palladium nitrate, silver nitrate, and metal niobium pentachloride of Group VB and dissolve them in hydrochloric acid to obtain a mixed solution;

[0026] γ-Al 2 o 3 Put it in a fluidized bed reactor with a temperature of 110°C, and then spray the above mixed solution evenly on the carrier to obtain a composite carrier, dry it, roast it at 250°C for 3 hours, and reduce it at 250°C for 3 hours under the condition of hydrogen, namely hydrogenation catalyst.

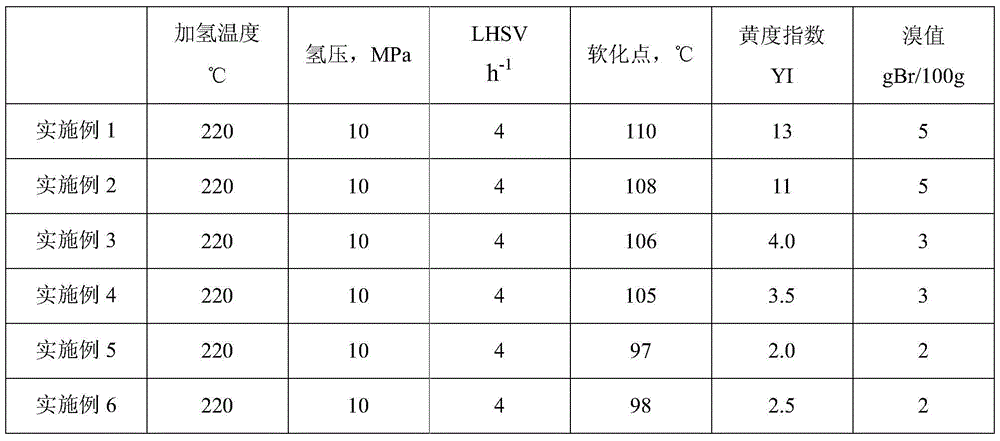

[0027] The parameters of Examples 2-6 are shown in Table 1, and the preparation method is the same as in Example 1.

[0028] Catalyst performance evaluation: Dissolve the petroleum resin to be hydrogenated with the initial Gar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com