External Vibration Assisted Milling Method

A milling and vibrating table technology, applied in the field of cutting processing, can solve problems such as few reports on vibration cutting technology research, inability to guarantee machining accuracy, and inability to adjust vibration frequency, so as to expand the scope of processing, improve the quality of the machined surface, reduce Effect of average cutting force and cutting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

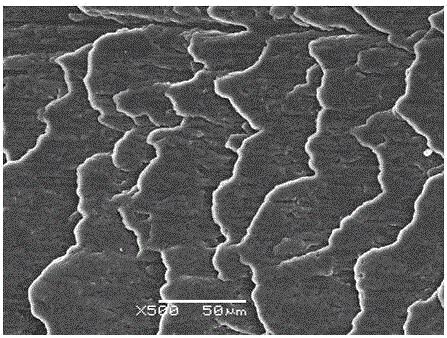

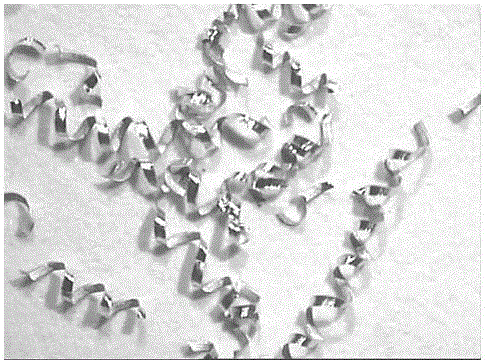

[0018] Horizontal unidirectional vibration processing:

[0019] The processing method adopts a device including a vibrating table, a machine tool table, a milling cutter, a machine tool spindle, a four-channel signal generator, and a four-channel power amplifier. The vibrating table is fixedly installed on the machine tool table, and the workpiece to be processed is fixedly installed on the vibrating table. The vibrating table is communicated with the four-channel power amplifier, and the four-channel power amplifier is communicated with the four-channel signal generator; the vibrating table includes a transverse vibrating plate and a longitudinal vibrating plate, the longitudinal vibrating plate is installed in the groove of the transverse vibrating plate, and the The vertical piezoelectric ceramic vibrator is arranged on both sides of the vertical direction, the horizontal vibrating plate is installed in the groove of the vibrating table, the horizontal piezoelectric ceramic ...

Embodiment 2

[0022] Longitudinal unidirectional vibration processing:

[0023] The processing method adopts a device including a vibrating table, a machine tool table, a milling cutter, a machine tool spindle, a four-channel signal generator, and a four-channel power amplifier. The vibrating table is fixedly installed on the machine tool table, and the workpiece to be processed is fixedly installed on the vibrating table. The vibrating table is communicated with the four-channel power amplifier, and the four-channel power amplifier is communicated with the four-channel signal generator; the vibrating table includes a transverse vibrating plate and a longitudinal vibrating plate, the longitudinal vibrating plate is installed in the groove of the transverse vibrating plate, and the The vertical piezoelectric ceramic vibrator is arranged on both sides of the vertical direction, the horizontal vibrating plate is installed in the groove of the vibrating table, the horizontal piezoelectric cerami...

Embodiment 3

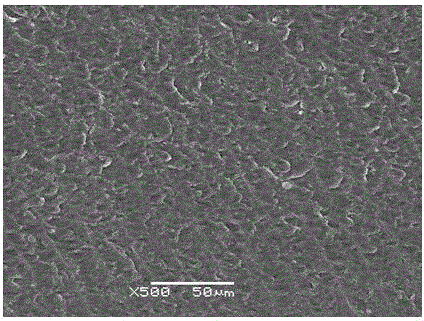

[0026] Horizontal and vertical two-way vibration processing:

[0027] The processing method adopts a device including a vibrating table, a machine tool table, a milling cutter, a machine tool spindle, a four-channel signal generator, and a four-channel power amplifier. The vibrating table is fixedly installed on the machine tool table, and the workpiece to be processed is fixedly installed on the vibrating table. The vibrating table is communicated with the four-channel power amplifier, and the four-channel power amplifier is communicated with the four-channel signal generator; the vibrating table includes a transverse vibrating plate and a longitudinal vibrating plate, the longitudinal vibrating plate is installed in the groove of the transverse vibrating plate, and the The vertical piezoelectric ceramic vibrator is arranged on both sides of the vertical direction, the horizontal vibrating plate is installed in the groove of the vibrating table, the horizontal piezoelectric ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com