A kind of preparation method of nanoscale titanium silicon molecular sieve

A titanium-silicon molecular sieve, nano-scale technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reduced specific surface area, reduced catalytic performance of molecular sieves, etc., to achieve good catalytic performance and save energy Production procedure and cost control, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

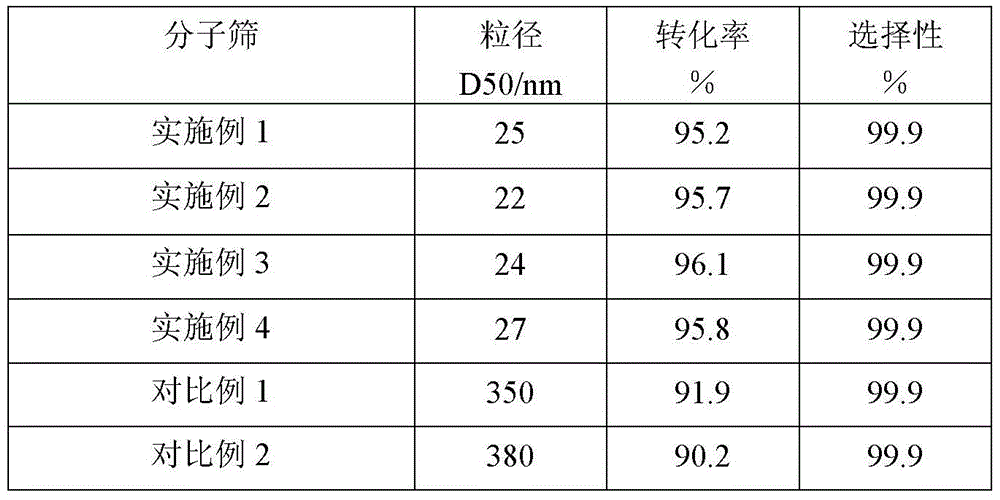

Examples

Embodiment 1

[0021] (1) After mixing the silicon source and the titanium source, add them to the aqueous solution of tetrapropylammonium hydroxide and stir them fully, and hydrolyze them for 0.5h at 0°C to obtain the hydrolyzed solution of the silicon source and the titanium source, the molar composition of which is Si:Ti: Tetrapropylammonium hydroxide: water=1: 0.01: 0.03: 1;

[0022] (2) Remove alcohol from the obtained hydrolysis solution at 50° C. for 3 hours, continuously add water to it during the alcohol removal process to prevent gelation, and the quality of the solution after adding water does not exceed the quality before alcohol removal;

[0023] (3) After removing the alcohol, the mother liquor is put into a closed reactor for pre-crystallization at 100°C for 0.5h, and then a certain amount of tetramethylguanidine is added, wherein the molar ratio Si:tetramethylguanidine=1:0.05;

[0024] (4) Continue to put the above mixed solution into a closed reactor for hydrothermal crystal...

Embodiment 2

[0026] (1) After mixing the silicon source and the titanium source, add them to the aqueous solution of tetraethylammonium hydroxide and stir fully, hydrolyze for 5 hours at 50° C. to obtain the hydrolysis solution of the silicon source and the titanium source, and its molar composition is Si: Ti: tetra Ethyl ammonium hydroxide: water = 1: 0.05: 0.6: 100;

[0027] (2) Dealcoholize the obtained hydrolyzed solution at 60° C. for 2 h, continuously add water to it during the process of dealcoholization to prevent gelation, and the quality of the solution after adding water does not exceed the quality before dealcoholization;

[0028] (3) After removing the alcohol, the mother liquor is put into a closed reactor for pre-crystallization at 150° C. for 10 h, and then a certain amount of tetramethylurea is added, wherein the molar ratio Si: tetramethylurea = 1: 0.6;

[0029] (4) Continue to put the above mixed solution into a closed reaction kettle for hydrothermal crystallization at ...

Embodiment 3

[0031] (1) After mixing the silicon source and the titanium source, add them to the aqueous solution of tetramethylammonium hydroxide and stir fully, and hydrolyze for 1 hour at 50° C. to obtain the hydrolyzed solution of the silicon source and the titanium source, and its molar composition is Si: Ti: tetramethylammonium hydroxide Methyl ammonium hydroxide water = 1: 0.03: 0.2: 20;

[0032] (2) dealcoholize the obtained hydrolyzed solution at 85° C. for 0.5 h, continuously add water to it during the process of dealcoholization to prevent gelation, and the quality of the solution after adding water does not exceed the quality before dealcoholization;

[0033] (3) After alcohol removal, the mother liquor was put into a closed reactor for pre-crystallization at 120° C. for 4 hours, and then a certain amount of tetramethylguanidine was added, wherein the molar ratio Si:tetramethylguanidine=1:0.2.

[0034] (4) Continue to put the above mixed solution into a closed reactor for hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com