A kind of synthetic method of titanium-silicon molecular sieve with high skeleton titanium content

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve problems such as increasing production process and cost, increasing maintenance costs, and equipment corrosion, and avoiding The formation of non-framework titanium, the effect of reducing the mismatch of hydrolysis rate and reducing the loss of framework titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

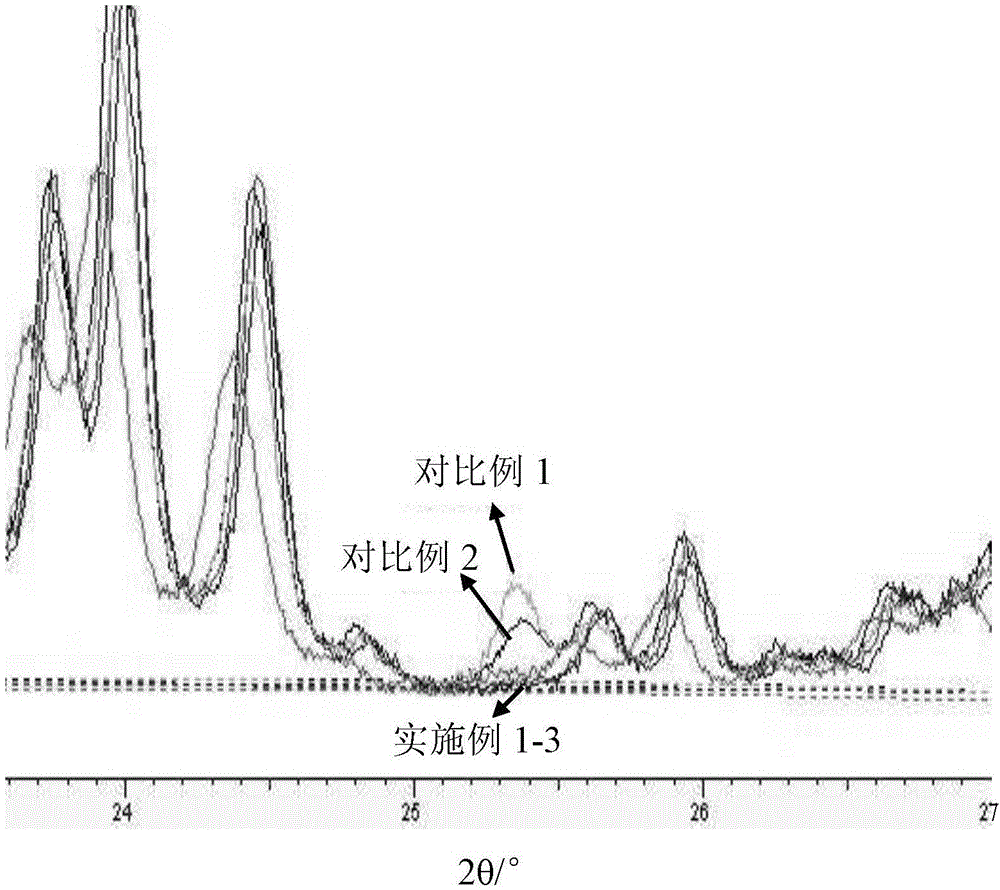

Examples

Embodiment 1

[0020] (1) After mixing the silicon source and the titanium source, add them to the aqueous solution of tetrapropylammonium hydroxide and stir them fully, and hydrolyze them for 0.5h at 0°C to obtain the hydrolyzed solution of the silicon source and the titanium source, the molar composition of which is Si:Ti: Tetrapropyl ammonium hydroxide=1: 0.01: 0.03, the massfraction of tetrapropyl ammonium hydroxide relative to water is 3%;

[0021] (2) The obtained hydrolysis solution is dealcoholized step by step, first dealcoholized at 50°C until the mass fraction of tetrapropylammonium hydroxide relative to water is 15%, and then dealcoholized at 61°C to tetrapropylammonium hydroxide Ammonium hydroxide is 21% relative to the massfraction of water;

[0022] (3) After alcohol removal, the mother liquor is put into a closed reaction kettle for pre-crystallization at 100° C. for 0.5 h, and then a certain amount of aliphatic amine compound n-butylamine is added, wherein the molar ratio Si...

Embodiment 2

[0025] (1) After mixing the silicon source and the titanium source, add them to the aqueous solution of tetraethylammonium hydroxide and stir fully, hydrolyze for 5 hours at 50° C. to obtain the hydrolysis solution of the silicon source and the titanium source, and its molar composition is Si: Ti: tetra Ethyl ammonium hydroxide=1: 0.05: 0.6, the mass fraction of tetraethyl ammonium hydroxide relative to water is 14%;

[0026] (2) The obtained hydrolysis solution is dealcoholized step by step, first dealcoholized at 60°C to tetraethylammonium hydroxide relative to the mass fraction of water is 20%, and then dealcoholized at 85°C to tetraethylammonium hydroxide Ammonium hydroxide is 50% relative to the massfraction of water;

[0027] (3) After alcohol removal, the mother liquor is put into a closed reaction kettle for pre-crystallization at 150° C. for 10 h, and then a certain amount of ethylamine is added, wherein the molar ratio Si:ethylamine=1:0.6;

[0028] (4) Continue to p...

Embodiment 3

[0030] (1) After mixing the silicon source and the titanium source, add them to the aqueous solution of tetramethylammonium hydroxide and stir fully, and hydrolyze for 1 hour at 50° C. to obtain the hydrolyzed solution of the silicon source and the titanium source, and its molar composition is Si: Ti: tetramethylammonium hydroxide Methyl ammonium hydroxide=1: 0.03: 0.2, the mass fraction of tetramethyl ammonium hydroxide relative to water is 10%;

[0031] (2) The obtained hydrolysis solution is dealcoholized step by step, first dealcoholized at 60°C to a mass fraction of tetramethylammonium hydroxide relative to water of 15%, and then dealcoholized at 80°C to tetramethylammonium hydroxide Ammonium hydroxide is 45% relative to the massfraction of water;

[0032] (3) After alcohol removal, the mother liquor is put into a closed reaction kettle for pre-crystallization at 120° C. for 4 hours, and then a certain amount of tri-n-propylamine is added, wherein the molar ratio Si:tri-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com