Method for producing organic fertilizer by treating sludge by use of microbial technology

A microbial technology and organic fertilizer technology, which is applied in the field of using microbial technology to treat sludge to produce organic fertilizer, can solve the problems of inability to kill pathogenic bacteria, and the organic matter cannot be well humified, and achieve the effect of short treatment period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A method for producing organic fertilizer by treating sludge with microbial technology, the steps are as follows:

[0019] 1) Dewater the sludge so that the moisture content of the sludge is 80%;

[0020] 2) The above dewatered sludge was subjected to constant temperature hydrothermal treatment at 121°C for 3 hours;

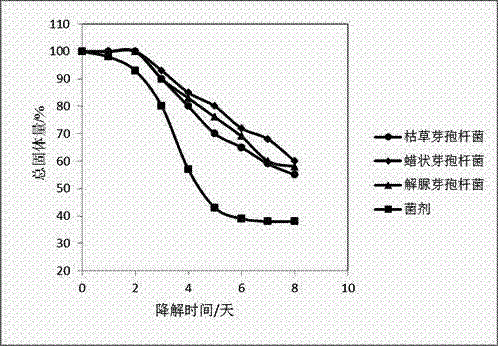

[0021] 3) Use lysis broth (LB) medium to cultivate microbial bacteria. The lysis broth (LB) medium is composed of tryptone, yeast extract, sodium chloride and deionized water. The concentration of each component in the mixture is It is tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, the pH of the mixture is 7.4; the culture method is to culture on a shaker at 50°C for 24 hours at a speed of 150rpm; The ratio is 1:1000 and inoculated in the sludge. The microorganisms are a mixture of Bacillus subtilis, Bacillus cereus and Bacillus urealyticum, and the mass share of each component is 40 parts of Bacillus subtilis and 40 parts of Bacillus cereus. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com