Method for producing organic fertilizer by use of pretreated sludge

An organic fertilizer and pretreatment technology, applied in the preparation of organic fertilizers, organic fertilizers, sewage/sludge fertilizers, etc., can solve the problems of not being able to kill pathogenic bacteria, not being able to humify organic matter well, and achieving easy degradation. The effect of increasing organic matter content and promoting fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

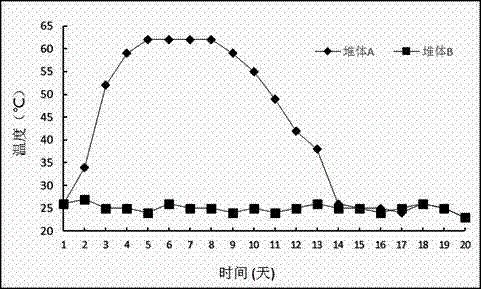

Image

Examples

Embodiment

[0016] A kind of method utilizing pretreatment sludge to produce organic fertilizer, the steps are as follows:

[0017] 1) Put 5kg of dewatered sludge with a water content of 80% into an autoclave and sterilize at 121°C for 3 hours;

[0018] 2) Crush the chaff to a particle size of 90-100 mesh, take 5kg of the chaff with a moisture content of 9% and mix it with the above high-temperature treated sludge to obtain a mixture, then add 1kg of nutrient solution to obtain a mixed material, which is marked as heap Body A, the nutrient solution is a mixed solution of sodium chloride, potassium nitrate, magnesium sulfate, ferrous sulfate, manganese sulfate and zinc sulfate dissolved in deionized water, sodium chloride, potassium nitrate, magnesium sulfate, sulfuric acid The mass ratio of ferrous iron, manganese sulfate and zinc sulfate is 2:1:1:1:1:1, and the concentration of sodium chloride in the mixed solution is 80g / L;

[0019] 3) Add sewage from the aeration tank of the urban sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com