Method for extracting procyanidine from grape seeds

A proanthocyanidin and grape seed technology, applied in the direction of organic chemistry, can solve the problems of proanthocyanidin composition, many dissolved impurities, and long extraction time, so as to save the purification of macroporous adsorption resin, and the subsequent purification steps are simple and avoid Effects of prolonged exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

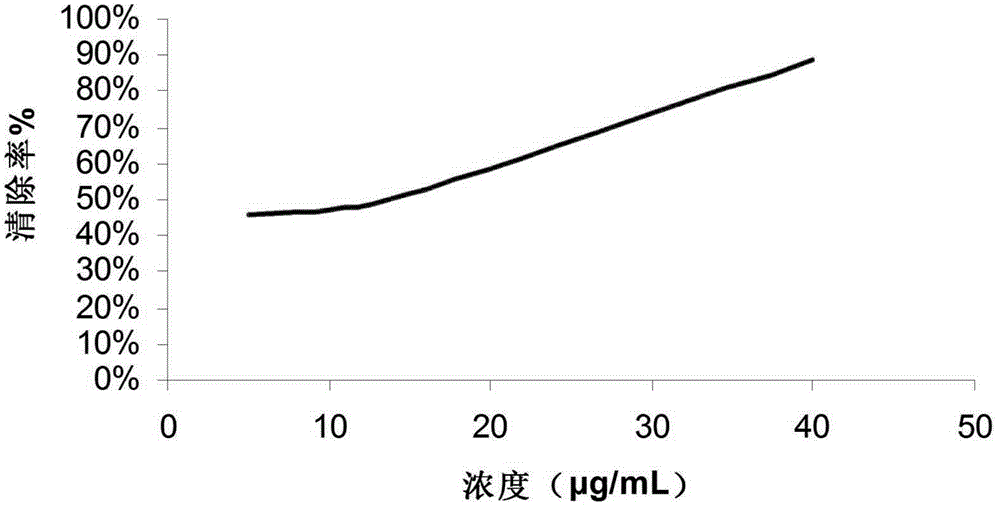

Embodiment 1

[0023] The degreased grape seeds were crushed to 60 mesh, 100 g was weighed and 1200 g of ethyl acetate was added, and ultrasonic treatment was performed at a frequency of 80 kHz and a power of 250 W for 30 min. Grape seed particles are filtered out, the filtrate is concentrated under reduced pressure and ethyl acetate is recovered to obtain a crude extract , the crude extract Store at low temperature and avoid light; add 1000g of purified water to grape seed granules, add 8g of cellulase, enzymolyze at 45°C for 40min, and perform ultrasonic treatment for 5min every 10min, ultrasonic frequency 80kHz, power 250W; Add 1000 g of ethyl acetate to the solution, and extract with the same ultrasonic conditions as above for 30 min. Separate the ethyl acetate layer afterwards, concentrate under reduced pressure, reclaim ethyl acetate, the crude extract obtained Store at low temperature and avoid light; adjust the pH of the remaining aqueous solution containing grape seed particles...

Embodiment 2

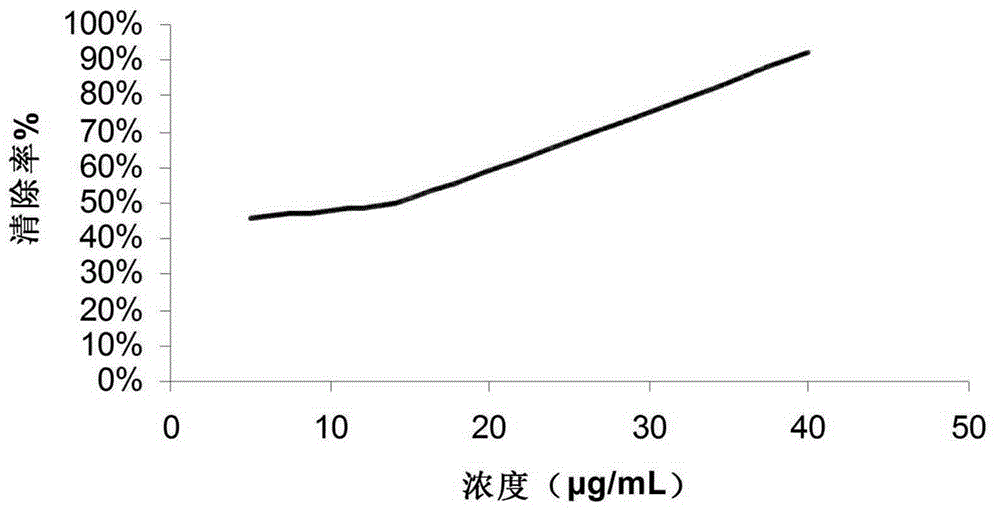

[0025] The degreased grape seeds were crushed to 80 mesh, 200 g was weighed and 2000 g of ethyl acetate was added, and ultrasonic treatment was performed at a frequency of 80 kHz and a power of 250 W for 40 min. Grape seed particles are filtered out, the filtrate is concentrated under reduced pressure and ethyl acetate is recovered to obtain a crude extract , the crude extract Store at low temperature and avoid light; add 2000g of purified water to grape seed granules, add 12g of cellulase, enzymolyze at 40°C for 40min, and perform ultrasonic treatment for 5min every 10min, ultrasonic frequency 80kHz, power 250W; Add 2000 g of ethyl acetate to the solution, and extract for 40 min under the same ultrasonic conditions as above. Separate the ethyl acetate layer afterwards, concentrate under reduced pressure, reclaim ethyl acetate, the crude extract obtained Store at low temperature and avoid light; adjust the pH of the remaining aqueous solution containing grape seed particl...

Embodiment 3

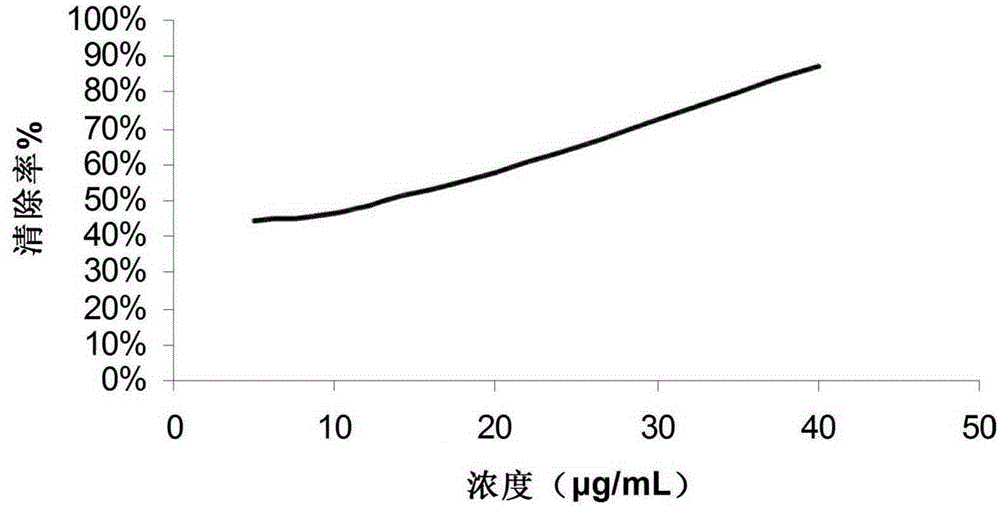

[0027] The degreased grape seeds were crushed to 50 mesh, 100 g was weighed and added into a closed container and 1200 g of ethyl acetate was added, filled with nitrogen, and ultrasonically treated at a frequency of 80 kHz and a power of 250 W for 40 min. Grape seed particles are filtered out, the filtrate is concentrated under reduced pressure and ethyl acetate is recovered to obtain a crude extract , the crude extract Store at low temperature and avoid light; add 1000g of purified water and 10g of cellulase to the filtered grape seed particles, place in a closed container and fill with nitrogen, enzymatically hydrolyze at 45°C for 40min, and perform ultrasonic treatment for 5min every 10min. Ultrasonic frequency 80kHz, power 250W; add 1000g ethyl acetate to the solution after enzymatic hydrolysis, and extract under the same ultrasonic conditions for 40min. Separate the ethyl acetate layer afterwards, concentrate under reduced pressure, reclaim ethyl acetate, the crude ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com