A simple and controllable low-cost industrial preparation method of high-strength heat-resistant PLA products

A low-cost, high-strength technology, applied in the field of biodegradable plastics, can solve the problems of difficulty in obtaining good synchronous regulation of heat resistance and mechanical strength, and the reduction of mechanical properties of PLLA/PDLA stereocomplexes. The effect of facilitating continuous production and increasing SC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0022] (1) Raw material drying: fully dry PLLA and PDLA so that the moisture content is lower than 0.005%;

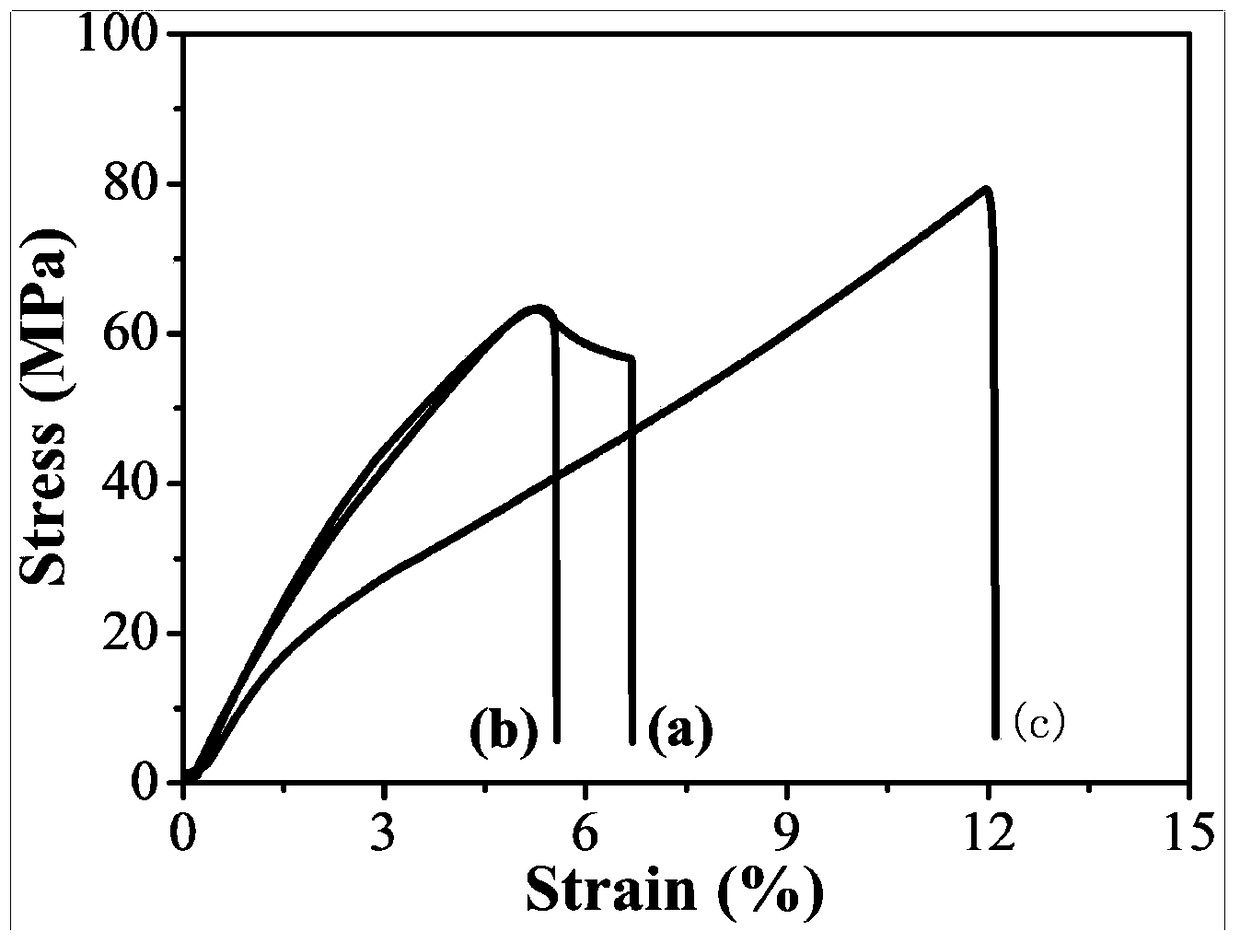

[0023] (2) Twin-screw extrusion blending and compounding, high-speed stretching: 3-10wt% PDLA is fully mixed with the matrix PLLA and then melted and compounded with the twin-screw extruder, and then passed through the roller from the narrow slot die at high speed Pulling out, the drawing ratio is controlled at 1-15 to form a highly oriented sheet, and the cold air blast cooling is carried out synchronously during the pulling process. See Table 1 for the specific formulation and extrusion compounding process parameters.

[0024] (3) Product molding: collect PLLA / PDLA extrudates and directly introduce them into the feeding port of the injection molding machine for injection molding. The specific molding process parameters are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com